Industry 4.0

With so much noise around Industry 4.0 and contradicting definitions from one person to the next, it’s no surprise to see why so many schools and teachers don’t know where to begin in training students in the classroom. Toolkit is proud to be the undisputed leader in providing schools and industry professionals Industry 4.0 Training Solutions.

How does one identify the important topics and skills to cover in the classroom when there are so many areas and directions one could take?

Toolkit is here to help with this. Lean on us as you prepare your students for the 4th Industrial Revolution, and we will guide you with the industry’s most intuitive and most robust portfolio of Industry 4.0 training solutions on the market.

From smart devices, IO-link, collaborative and industrial robots, networking and communication protocols, mobile robots, Management Execution Softwares, Predictive Maintenance, Cybersecurity, Data Analytics and more – training for a rapidly digitalizing and changing manufacturing world can be a daunting challenge.

History of i4o

The Fourth Industrial Revolution (Industry 4.0) is a term for the current state of digital expansion seen across the globe and within every industry. It’s a new era that builds on and extends the impact of digitization in new and unanticipated ways. Industry 4.0 has been made possible by digitizing and automating the computerization of previous industrial revolutions through autonomous, cyber-physical systems and machine learning. Rapid disruptive advances in technology like artificial intelligence, robotics, blockchain, and 3D printing have created uncertainty and fear of increased unemployment and inequality.

Recent studies from McKinsey estimate that nearly 375 million workers may need to switch occupational categories as a result of the Industry 4.0. For advanced economies, up to one-third of the 2030 workforce in the United States and Germany, and nearly half in Japan may need to learn new skills and find other occupations. Jobs are not as cut and dry as they once were; most occupations require a set of varied skills and tasks. But rather than being replaced by robots, many jobs will see an increase in the amount of tasks which can be automated.

In fact, McKinsey found that less than 5% of global occupations can be replaced by automation. However, in about 60% of occupations, about a third of associated tasks could be automated, causing workers to either find new jobs or upgrade skills to meet demands.

Automation and Jobs

The low-skilled, repetitive jobs that are at highest risk for replacement through automation will also require new high-skilled positions focused on management, quality control, and require increased supervision. Cost savings in production could, in theory, be translated to reduced product price and thus increased demand, actually helping the economy. Which could potentially increase demand for partly automated occupations.

Toolkit prides itself on providing learners with the Industry 4.0 cyber physical training systems and certifications to prepare the next generation of the workforce.

Showing 1–12 of 13 results

-

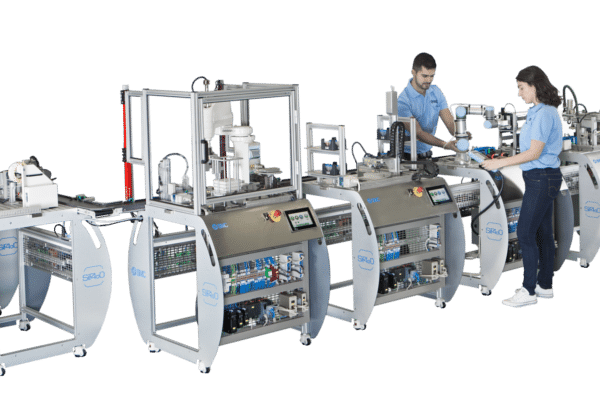

SMC Smart Innovative Factory Training System

Take a look at the most remarkable, fully-connected Industry 4.0 Training Platform on the market for hands-on training, exploration, and research in advanced manufacturing industries: SMC’s SIF-400.

SMC’s Industry 4.0 Smart Innovative Factory reproduces an industrial, cyber-physical smart factory – in both production applications and supply chain applications – for a school to provide real-world advanced manufacturing training. The training system is a modular design comprised of 14 interconnected stations for hands-on training and research of connected systems, operational data and data analytics, IIoT, predictive and preventative maintenance, management execution software (MES), inventory tracking and control, cybersecurity, and more.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

SMC Robot Training System RTS-200

SMC is proud to bring this one-of-a-kind Robot Training Platform to schools for real world robot training!

The RTS-200 training system provides participants with a hardware platform for performing hands-on development for robotic operations. The mobile platform includes various applications which can be quickly installed to provide advanced activities, expanding the learning objectives beyond simple pick and place functions. The design allows participants to advance from basic programming to integration of various technologies including electrical controls, pneumatics, controllers, artificial vision, sensors and more – all with simple drop-in training panels.

Have multiple robots? The RTS-200 allows for multiple robot models and brands to be dropped in as well!

SMC’s Partnership with Universal Robots allows students to get real-world certification on Universal Robots!

-

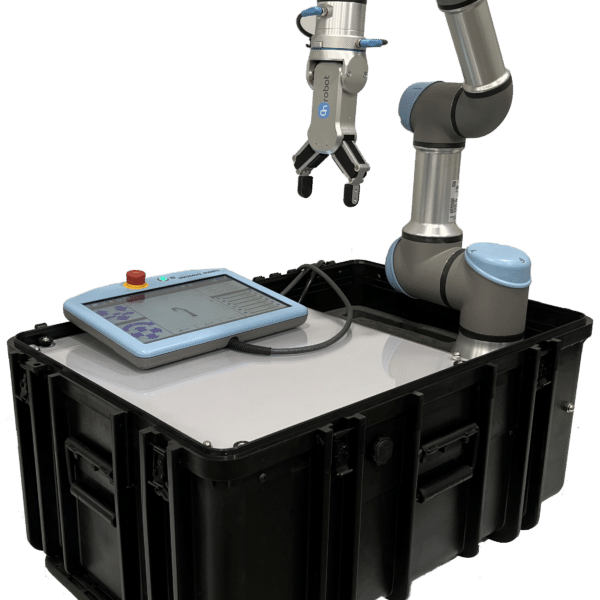

Universal Robot Suitcase Robot Training System

Toolkit Technologies is proud to bring this one-of-a-kind Robot Training Platform to schools for real world robot training!

The RTS-100 combines the modularity and industrial training capabilities of our RTS-200 Robot Training Cart with the advantages of a portable and compact, rugged suitcase form factor. This allows for easy and safe transport to remote training locations, satellite campuses, recruiting events and more. Additionally, the rugged and compact storage case allows for your robot training systems to be easily stored when not in use. Classrooms limited on space particularly enjoy the compact footprint of the RTS-100.

Toolkit’s Portable Robot Training System includes the controller, workpieces, training activities, curriculum, and all required components for successful robotics training. Foam inserts allow for safe and organized storage for all components and workpieces.

The RTS-100 is a great choice for providing industrial training activities around the Universal Robot UR3e, while giving you the flexibility and redeployment advantages of a mobile and portable training system. Reach out for alternative robot options such as Mecademic, uFactory, and more!

-

5-Station Smart Innovative Factory

The 5-Station Configuration of the SMC SIF-400 takes a condensed yet robust look at hands-down the most remarkable, fully-connected Industry 4.0 Training Platform on the market for hands-on training, exploration, and research in advanced manufacturing industries: SMC’s SIF-400.

SMC’s Industry 4.0 Smart Innovative Factory reproduces an industrial, cyber-physical smart factory – in both the production and supply chain – with a modular design of 14 interconnected stations for training and studies in connected systems, operational data and data analytics, IIoT, predictive and preventative maintenance, management execution software (MES), inventory tracking and control, cybersecurity, and more!

-

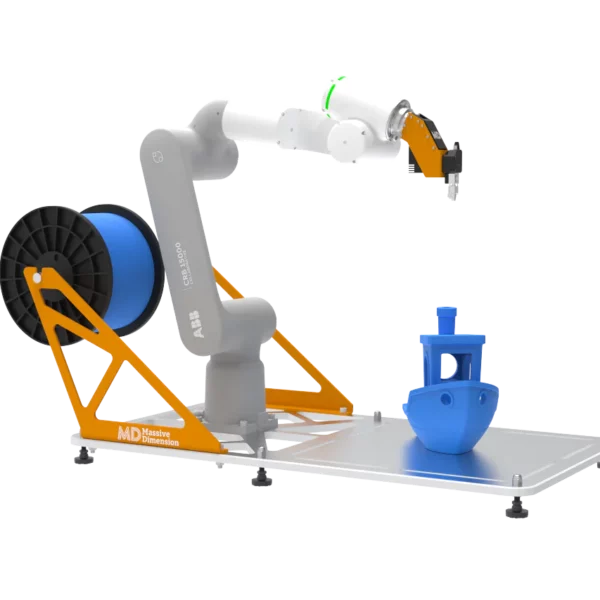

ABB Collaborative Robot 3D Printing

Have you ever wanted to print BIGGER with your classroom 3D printer? Or have you wanted to explore the capabilities of your industrial and collaborative robots?

We are proud to introduce the MDAC1 3D Printing System for Education, the first of its kind classroom robotic 3D printer!

The Collaborative Robot 3D Printing system features a GoFa CRB 15000 cobot and pioneering FDM 3D printing technology from Massive Dimension for unparalleled capabilities and excitement.

Now certified and authenticated by STEM.org!

-

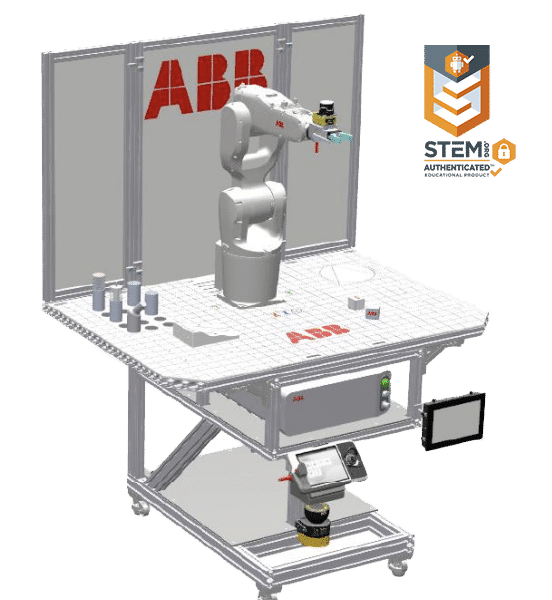

ABB Cobot FlexTrainer STEM Education Cell

Go Faster! Go Farther! Go Further! Go Train on ABB’s new Collaborative Robot, GoFa CRB 15000!

We are thrilled to bring ABB’s newest collaborative robot training system – the ABB Cobot FlexTrainer with ABB’s newest collaborative robot, the GoFa, to education.

The mobile training platform features a sleek design and various industry training applications. Paired beautifully via ABB RobotStudio, students can get hands-on training and virtual/digital solutions with AR/VR.

Now certified and authenticated by STEM.org!

-

ABB Fenceless FlexTrainer Robot Training System

The new ABB Fenceless FlexTrainer Cart was designed specifically for education. To bring students face-to-face with one of industry’s leading robots.The hands-on training cart utilizes ABB’s IRB 1200 or IRB 1100 industrial robots for practical, industry-driven skills training. The fenceless collaborative design allows open site-lines to the robot, maintaining safety with an ABB safety sensor located at the bottom of the cell.Now Certified and Authenticated by STEM.orgOther features of the FlexTrainer include:– ABB STEM Education Activity Tabletop (removable)

– Electric Gripper EoAT

– ABB 3D Printed STEM Education Activity Kit for hands-on training activities

– SMC Linear conveyor system

– HMI

– Integrated vision

– SMART Certification and Curriculum for STEM and Robotics

– Large casters for easy transportation

– Fits through a standard door

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.

-

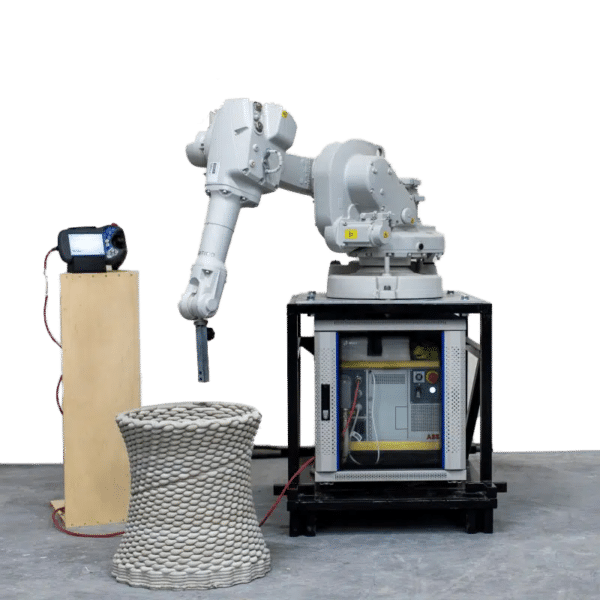

Robotic Concrete 3D Printing

3D print a house! Or a table, bench, or chair! Or perhaps a walking bridge or staircase! Introducing large-scale concrete 3d printing from TOOLKIT!

Toolkit is proud to be the exclusive education provider of large-scale Concrete 3D Printing for Training and Research. In partnership with the industrial leader and pioneer in the field, Vertico, we are thrilled to bring high schools, career centers, technical colleges and universities one of the most exciting new technologies for construction, automation and robotics.

Our system utilizes a high-precision industrial robot from ABB, equipped with state-of-the-art Concrete 3D Printing Technology, intuitive Control & Supervision Software, and Train-the-Trainer professional development.

We offer several models, including single and bicomponent printheads, small-scale lab printers and full-sized industrial systems capable of printing a house!

-

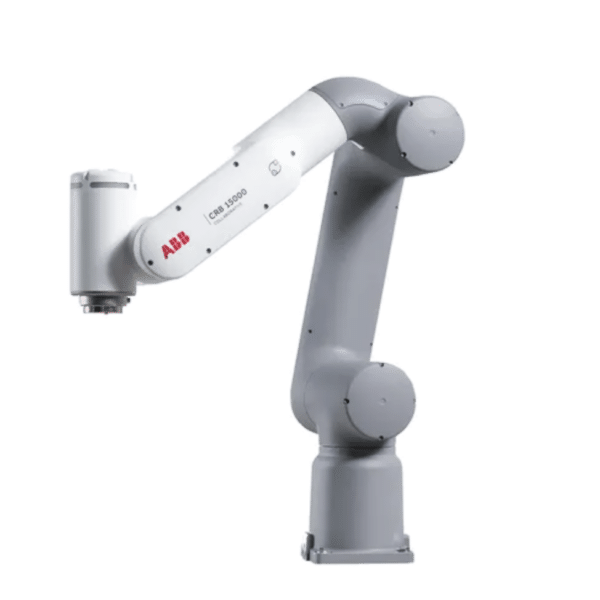

ABB GoFa CRB 15000 Collaborative Robot

Go Faster! Go Farther! Go Further! Go Train!

We are thrilled to bring ABB’s newest collaborative robot, the GoFa, with industry leading speed, precision, reach and more!

Ease-of-use is in focus here – with enhanced user-interaction capabilities, superior lead through, and ABB Wizard easy programming, training robotics and automation has never been more accessible.

Students can get hands-on industry-driven robotics experience from day 1 with unlimited training potential! Understanding the advantages of collaborative robotics and automation, machine tending, welding, pick & place, etc. has never been easier!

-

ABB IRB 14000 YuMi Collaborative Robot

The first robot to do it. Collaboratively. Uniquely and Effectively. She grabs attention and keeps it.

Best-in-class safety. Ultimate flexibility. Approachable design. ABB’s YuMi robot was engineered to work directly alongside your people and students, and boost productivity and training.

YuMi is the first truly collaborative dual-armed robot, designed for a world in which humans and robots work together. It heralds a new era of robotic coworkers which are able to work side-by-side on the same tasks as humans with extreme accuracy while ensuring the safety of those around it.

Available in single or double-arm configurations.

-

ABB IRB 1100 Industrial Robot

The ABB IRB 1100 industrial robot is a compact automation workhorse.

Aimed at increasing manufacturing productivity in highly automated industries – electronics, semiconductors, automotive, manufacturing, deburring, grinding, etc – the IRB 1100 provides up to 35% faster cycle times and best-in-class repeatability for high quality manufacturing. It consistently outperforms similar robots in terms of payload and position repeatability (RP) even when under space constraints.

For the classroom, there is no better compact industrial robot training platform with complete curriculum, training applications, industrial certification, industry-relevance, simulation softwares, and more.