Drop us a line today to schedule a time to discuss more!

Semiconductor Industry Training Initiative (SITI)

Toolkit's SITI (Semiconductor Industry Training Initiative) for the future of the semiconductor manufacturing industry is a complete, turn-key training program for schools, workforce development programs, and companies to provide best-in-class industrial training for semiconductor manufacturing professionals.

Training for semiconductor manufacturing requires deep understanding of highly specialized and heavily automated processes. Toolkit, in combination with the industry manufacturing experts at SMC, provide this holistic semiconductor industry training program for the long-term viability and health of semiconductor manufacturing businesses and the economy at large.

Learn more about SITI, associated SMC Industry microcredentials and certifications, and how to prepare for a new world of advanced manufacturing.

Key Training Areas of the Semiconductor Industry Training Initiative (SITI)

Toolkit and our partners at SMC are proud to offer education, training, and manufacturing institutions a turn-key, one-stop-shop for training in the semiconductor manufacturing industry.

SMC's invaluable experience working as the world's #1 automation supplier in the semiconductor industry brings a valuable and needed insight to industry training in the semiconductor field.

Below are a list of equipment and training material needed for a complete semiconductor training program.

Semiconductor Cleanroom Garments

The number one cause of attrition of workers in the semiconductor industry is, perhaps surprisingly, the "bunny suits" required to be worn in highly sensitive manufacturing areas. Because of this, Toolkit recommends all training for semiconductor-specific industries be performed in full cleanroom attire.

Semiconductor Electrical Training

Semiconductor industry technicians and professionals are expected to have a strong mastery of skills in troubleshooting and repairing electrical + electronic systems. Toolkit's Semiconductor Industry Training Initiative takes a deep dive into electrical concepts and technologies to provide learners with a strong foundation in electrical concepts. Students will master skills in Alternating Currents, Direct Currents, Solid State technologies, troubleshooting, and hand tools.

Semiconductor Pneumatics and Electropneumatics Training

Toolkit's Semiconductor Industry Training Initiative (SITI) provides a comprehensive training solution for semiconductor professionals in the area of pneumatics and electro-pnuematics systems. Students will learn various pneumatic technologies, such as actuators, control valves, pressure switches, cylinders, gauges, filters, and basic hand tools. Learners will be expected to follow installation instructions with minimal assistance, troubleshoot, identify induced flaws. Learners will become proficient in needed semiconductor industry skills such as conducting preventative maintenance routines on pneumatic systems and identifying and interpreting pneumatic components and technologies given pneumatic diagrams.

Semiconductor Vacuum Technology Training

Understanding and Repairing Vacuum technologies is a vital skill in the semiconductor manufacturing industry. Toolkit's Semiconductor Industry Training Initiative (SITI) brings industry-leading technologies from SMC to learners' fingertips to gain mastery over these important skills. Students are expected to learn and understand vacuum technologies, what creates vacuums, and how to create low/high/ulta high vacuum levels. Learners will master how to create vacuum pumps and gauges, how to perform preventative maintenance procedures, and how to troubleshoot and repair vacuum systems.

Programmable Logic Controller - PLCs

The SITI training program includes hands-on training and curriculum in PLC programming, a key automation components of manufacturing in the semiconductor industry. Students will learn key attributes and concepts behind PLCs and automated manufacturing, how to program automated systems, and how to troubleshoot integrated automation systems.

Semiconductor Robotics Training

Semiconductor manufacturing relies heavily on automated systems, automated manufacturing, and robotic systems to produce highly precise and consistent results. Semiconductor manufacturing technicians and professionals can be expected to program, maintain, calibrate, and repair automated robot systems. Learners who complete SMC's Semiconductor Industry Training Initiative will learn how to install automated systems that include robots, end effectors, automated material handling systems and more. Additionally, they will know how to repair, troubleshoot, and maintain all advanced manufacturing systems in the semiconductor industry.

Semiconductor Sensors Technology Training

Semiconductor manufacturing relies on sensors for quality control, quality assurance, and manufacturing. Students will be expected to know the ins-and-outs of industrial sensor types, how to install, calibrate, set tolerances, and integrated into advanced automation systems.

Advanced Manufacturing + Automation Training

Advanced Manufacturing and advanced automation is at the core of any semiconductor manufacturing environment. Semiconductors are the technologies they encompass are modern manufacturing marvels. Training for the Semiconductor Industry relies heavily on training in advanced manufacturing and automation, and their relevant technologies like robotics, machine vision, and more.

Semiconductor Training Systems

SMC Basic Electricity Mate (BEMATE-200)

The SMC BEMATE-200 AC/DC Training System is the portable basic electricity training system that allows learners to explore technologies and concepts around Alternating Currents, Direct Currents, and Solid State devices.

Students are challenged with real-world project-based exercises and then taught important industry-related troubleshooting skills.

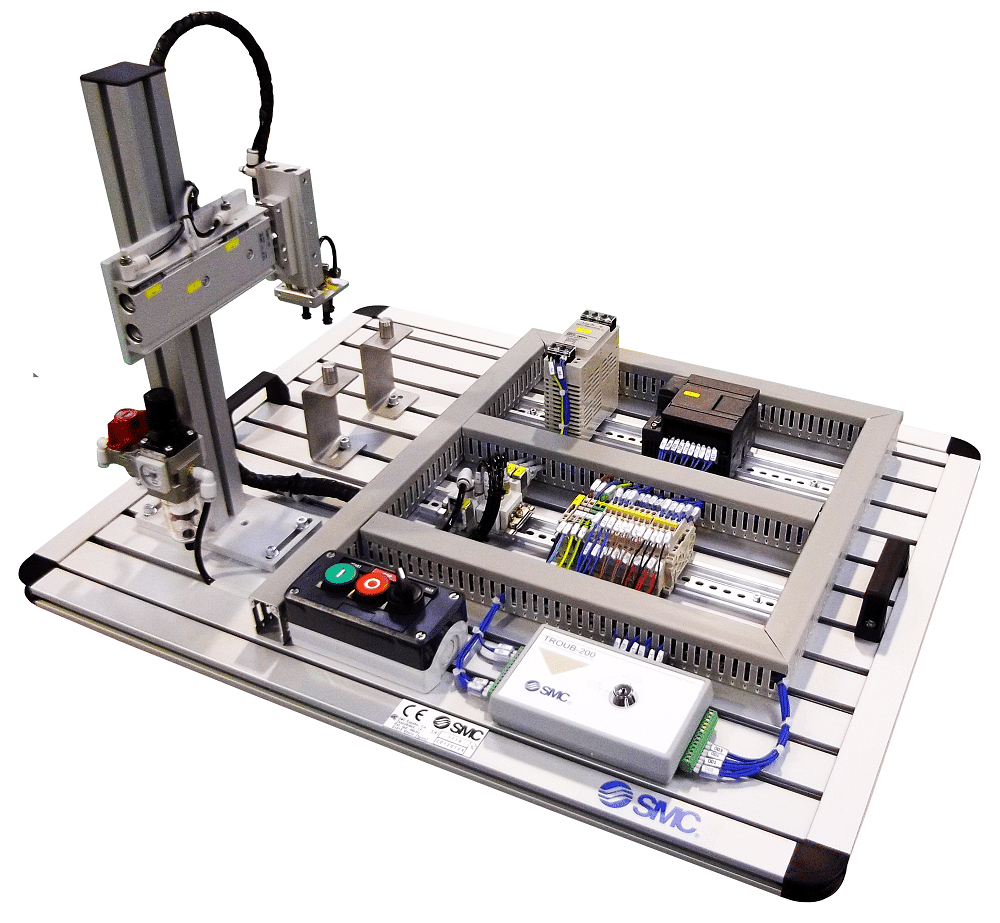

SMC PLC + HMI Training System (PCT-200)

SMC's Programmable Logic Controller + Human Machine Interface training system, the SMC PCT-200, provides the flexible learning system for hands-on training in automation and the semiconductor industry.

Students learn programming, automations systems integrations, remote programming, and troubleshooting on industrial-standard PLCs and software.

With PLC and HMI options from AllenBradley, Siemens, Omron, and more, SMC has the hands-on training solution for your semiconductor manufacturing training.

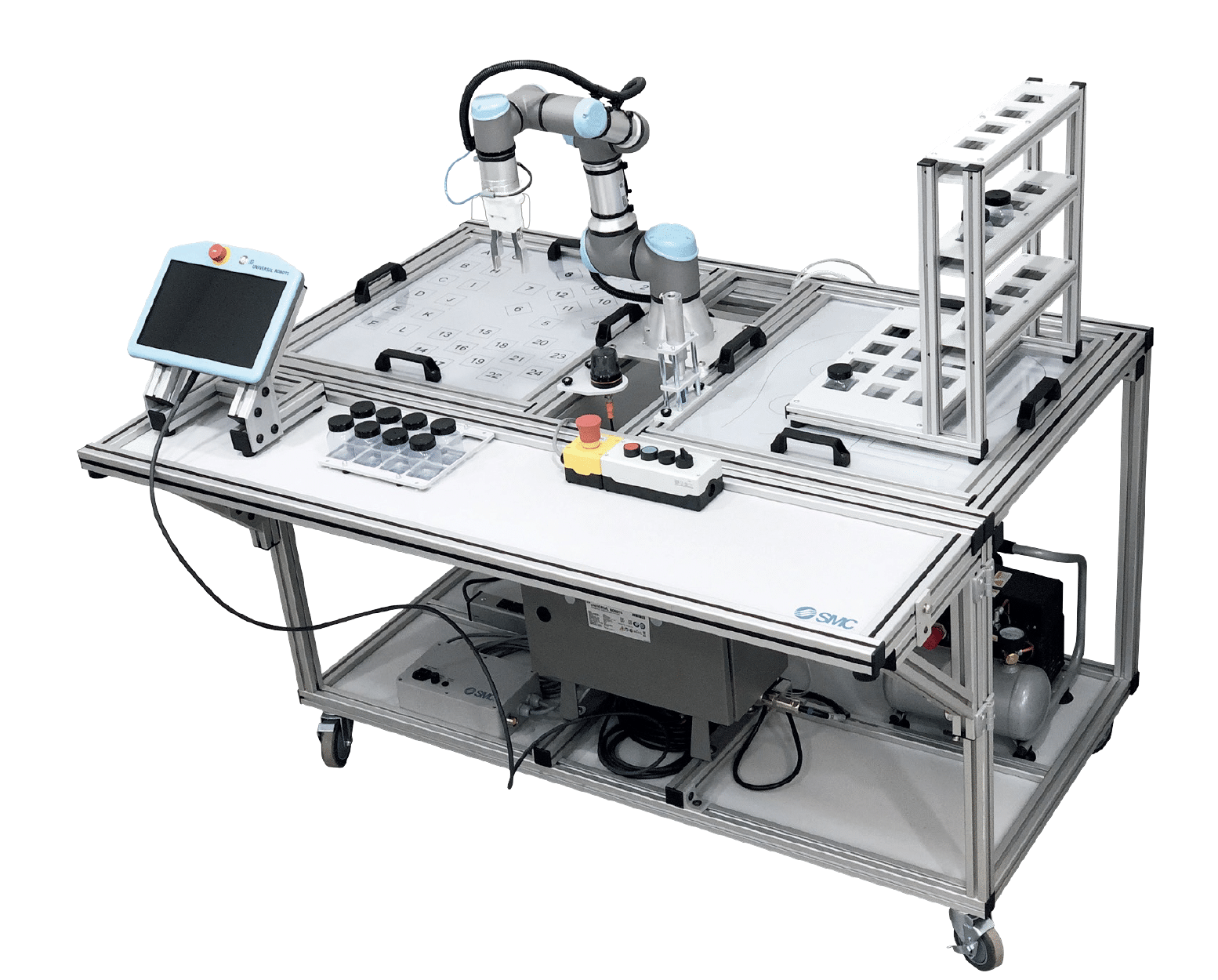

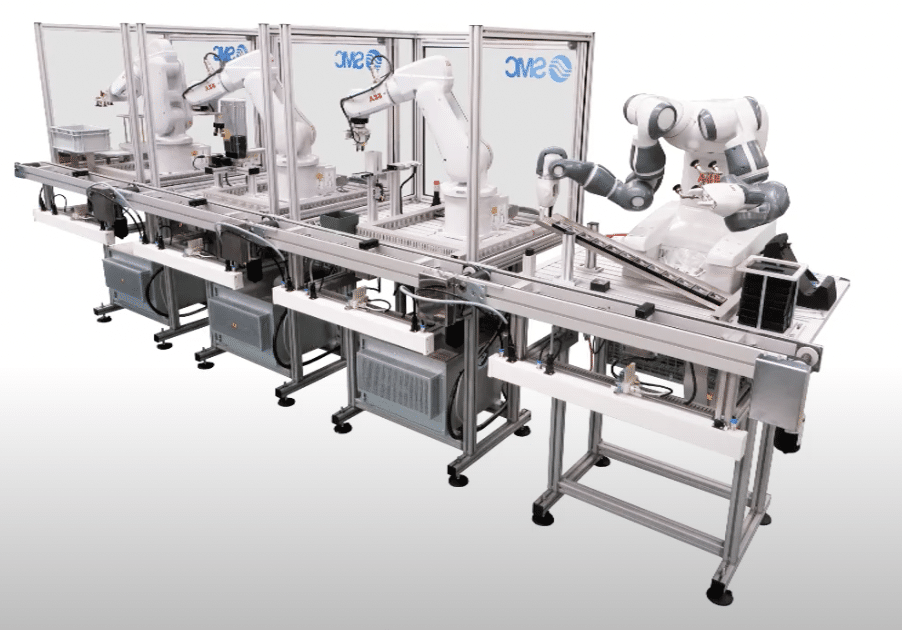

SMC Robot Training Systems (RTS-200)

Highly automated systems such as those found in the semiconductor manufacturing industry include both industrial, collaborative, and autonomous robots.

SMC's diverse training options for robotics include robots from any robot brand, such as ABB, Fanuc, Kuka, and Universal Robots. Stand-alone robot training systems such as the RTS-200, or integrated multiple-robot training solutions such as the RAS-200.

Complete with curriculum, practical activities, endless automation/integration possibilities, and industry relevant troubleshooting challenges, learners are well-prepared with the demands of industry through SMC's robot training systems.

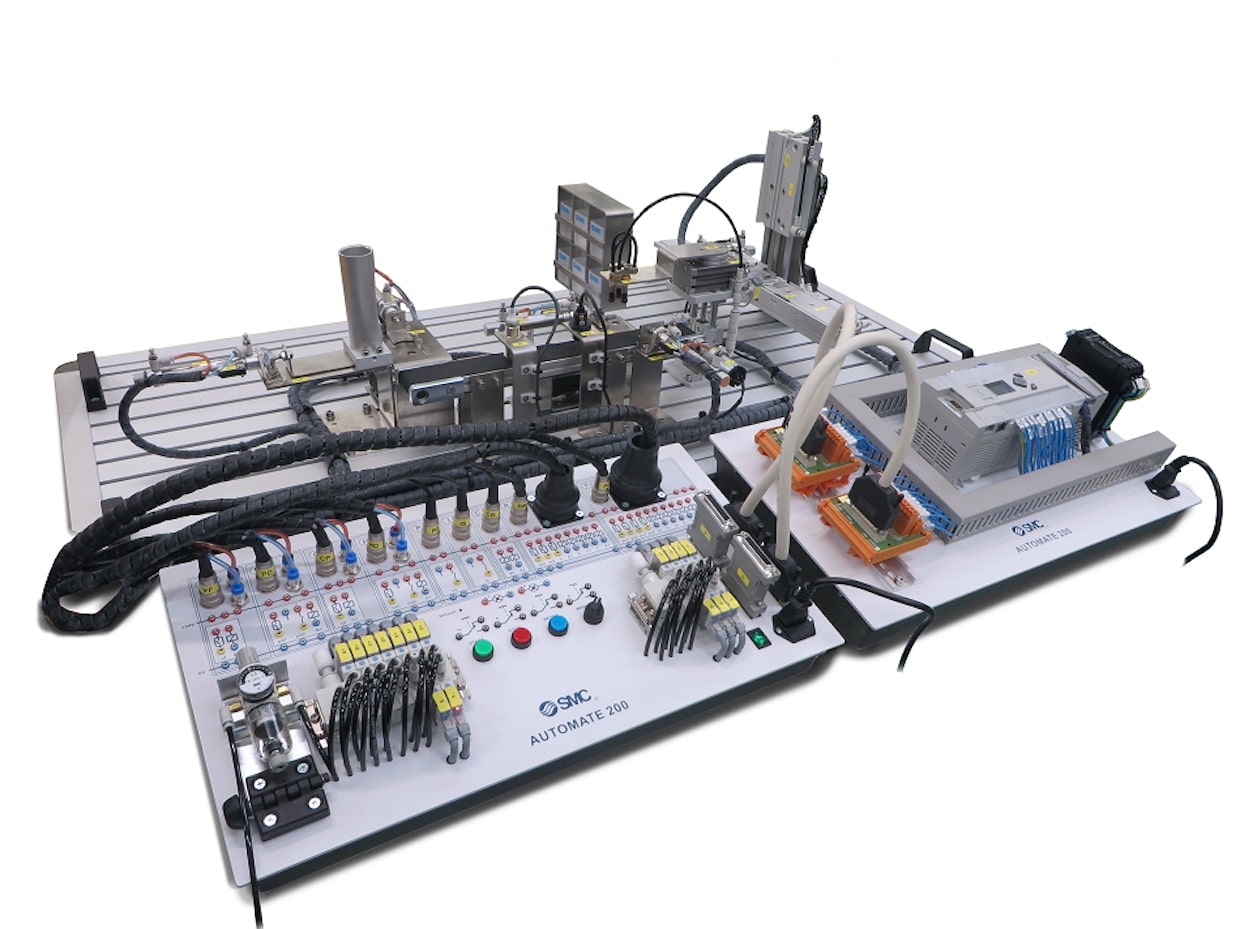

SMC Pneumatics + Electro-pneumatics Training System (Pneutrainer-400)

As the world's leading pneumatic and automation technology supplier to the semiconductor industry, SMC's pneumatics and electropneumatics training system (Pneutrainer-400) is a must have for semiconductor manufacturing training.

Complete with curriculum, simulation software, and practical activities, learners gain valuable industry insight and experience installing, maintaining and troubleshooting pneumatic cylinders, actuators, control valves, pressure switches, etc.

SMC Vacuum Technology Training System (VAC-200)

The semiconductor manufacturing industry heavily relies on vacuum technology for the movement of silicon wafers during the inspection process.

Vacuum technology also conveys small components such as resistors, capacitors and inductors during the production process.

Some of the components are as small as a grain of sand, and precision and cleanliness is of paramount importance.

SMC is the industry's leading supplier of vacuum technology components and systems, and SMC's Vacuum Training System is the best industry training solution to provide students with hands-on understanding of this important technology.

SMC Smart Sensors Training System (SensoTrainer-200)

There is no shortage of sensors in the semiconductor manufacturing industry, so SMC's SITI for semiconductor professionals includes sensor training systems at both the individual level and integrate systems level.

With the SMC SensoTrainer-200, learners can expect to understand what each sensor is, how they operate, how to maintain them, how to install sensors, repair them, and calibrate in various automation settings.

Learners can also expect to program sensors and automation systems to accomplish specific tasks, as well as troubleshoot advanced automation systems.

SMC's HIGHLY AUTOMATED SYSTEM (HAS-200)

The Highly Automated System is an integrated training system developed for, by, and in conjunction with INTEL for hands-on training in the semiconductor manufacturing industry.

Featuring all major industrial automation technologies for Industry 4.0 and advanced manufacturing training, the HAS-200 is the advanced semiconductor training system needed for students to apply individual learning areas developed throughout SITI to one integrated system.

Students will learn system integrations, programming, and troubleshooting on an industrial system with industrial perspective.

SMC's Industry 4.0 Smart Factory Training System

For further exploration of advanced manufacturing and heavily automated systems, SMC brings the Smart Innovative Factory for Industry 4.0 technologies to learners for deep exploration of integrated and connected systems.

With smart sensor technology, Management Execution System software, industrial robots, and all major technologies seen in the Semiconductor Manufacturing industry, the SMC Smart Factory training system is a thorough and holistic approach to industry training.