Electrical

Toolkit is proud to offer schools the very best Electrical Training Systems available for students to build their understanding and mastery of electrical technologies. The building blocks for careers in multiple pathways, electrical technologies are the important foundational learning blocks for students as they begin their studies.

Mastering electrical skills will lead to successful careers in fields such as Advanced Manufacturing, Skilled Trades, Mechatronics, HVAC, Alternative Energy, and Automotive Technologies, and more.

Electrical Skills

Students must learn basic concepts of electricity and electrical measurements. They must be able to analyze circuits, troubleshoot circuits, and understand differences between Alternating Currents (AC) and Direct Currents (DC). Learners will be expected to understand basic topics including inductance, capacitance, combination circuits, and transformers, along with series and parallel circuits.

Learners will be expected to wire industrial devices while also understanding electrical safety.

Job Outlook

Most jobs in CTE require a strong foundation in electrical technologies and concepts. From electricians to technicians, jobs in the electrical field are growing in need and pay. As technologies and systems grow more complex and advanced, the demand for increased training in electrical technologies is also growing.

Toolkit’s hands-on training systems combined with digital simulation solutions and eLearning provides students with needed industry-validated skills and certifications.

Showing 1–12 of 21 results

-

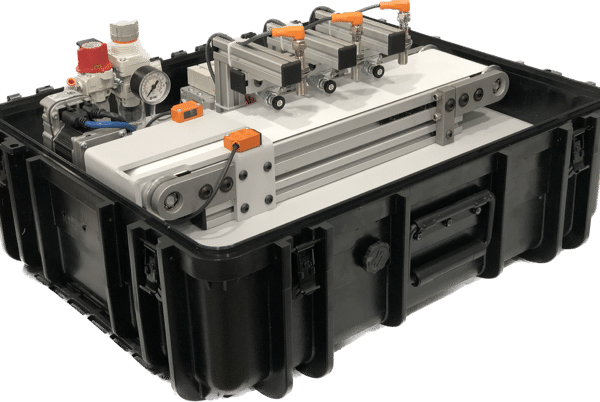

SMC Suitcase Conveyor Training Application

With the SMC PLC Training Applications, students can apply their programming, troubleshooting, and automation skills with real-world, industry-applicable training scenarios.

The Suitcase Conveyor Application allows students to connect the mobile trainer to an external PLC or the SMC PLC Training System (PCT-200) for expanded training opportunities and skills-development.

The conveyor and integrated sensors allow for students to program the PLC to sort and distribute workpieces and parts in an engaging and project-based learning approach.

-

SMC Programmable Logic Controller (PLC) Training System

Take your automation training to the next level with SMC’s Hands-on PLC Training System. With a mobile hard-shell suitcase, this versatile and expandable solution provides the perfect environment to learn about programmable controllers, digital I/O, analog I/O and human machine interfaces (HMIs).

Plus, with two external connection blocks, you can connect any external I/O devices directly to the controller. Get the most out of your training today with SMC’s PLC Training System!

-

SMC Industrial Controls Training System

Equip your students with the skills they need to succeed with the SMC Industrial Controls Trainer (ICT-200). Our flexible platform allows for hands-on experiments in wiring and troubleshooting of control circuits, giving students access to devices that enable them to connect and wire all circuit components directly.

With our system, students can operate, install, design, wire and troubleshoot (DC, AC) electric motor control circuits, helping them stay ahead in the competitive industrial control field.

A mobile suitcase option is available.

-

SMC Basic ACDC Electrical Training System (AC, DC, Solid State)

The SMC BEMATE-200 – Your Basic Electricity Mate – provides hardware for hands-on activities and the study of DC, AC and Solid State fundamentals. All devices are permanently mounted and can be quickly connected in a variety of configurations via Banana Jack connectors.

Users will be introduced to the function and use of various devices and circuits. In addition, test equipment and fault insertion activities will allow for development of troubleshooting skills.

-

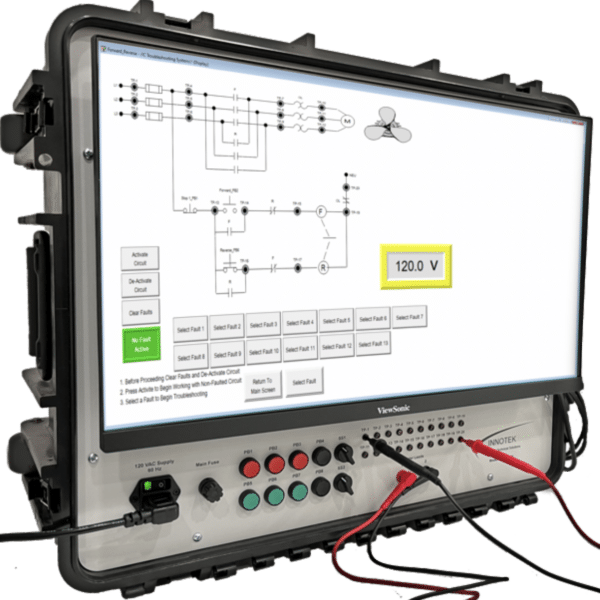

Electrical Troubleshooting System

We are excited to take your students’ and employees’ industrial troubleshooting skills to a whole new level with our Innotek Electrical Troubleshooting System, ETS-101.

The Electrical Troubleshooting System provides a hardware solution that introduces the fundamentals of troubleshooting electrical circuits in a sleek, portable, and approachable manner.

The unit is completely integrated into a portable suitcase allowing for easy transport. The unit provides circuits that are used in industrial applications, allowing participants to perform develop systematic troubleshooting skills.

Users can choose their electrical troubleshooting focus area and the circuit for students to troubleshoot.

-

Motor Troubleshooting Training System

The MTS-101 Motor Troubleshooting System provides hands-on hardware for the development of skills and assessment of motor troubleshooting principals. Learners will utilize test equipment including an ohmmeter and megohmmeter to determine the condition of a 3-phase AC motor.

Insertable Faults are included on the side of the training system to allow for practical troubleshooting and testing to take place.

-

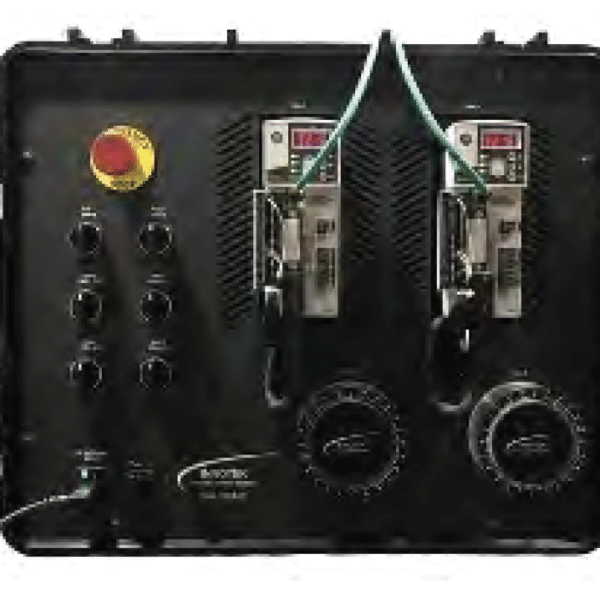

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

Conveyor and Logistics Automation Training System

The Conveyor and Logistics Automation Training System with Troubleshooting is our industrial training solution for school and companies looking for practical and realistic hands-on training activities in areas such as Maintenance, Troubleshooting, and Programming of industrial automation technologies commonly seen in warehouses, logistics settings, and industrial automation factories.

The mobile and modular system includes choices of PLC controller, Variable Frequency Drive, HMI’s, and conveyors. Conveyors stations can include: flatbed slider belt conveyors, roller bed belt conveyors, powered roller conveyor, plastic mesh conveyor, and more.

Up to 32 Troubleshooting Faults can be incorporated so students can troubleshoot and repair faulted components.

-

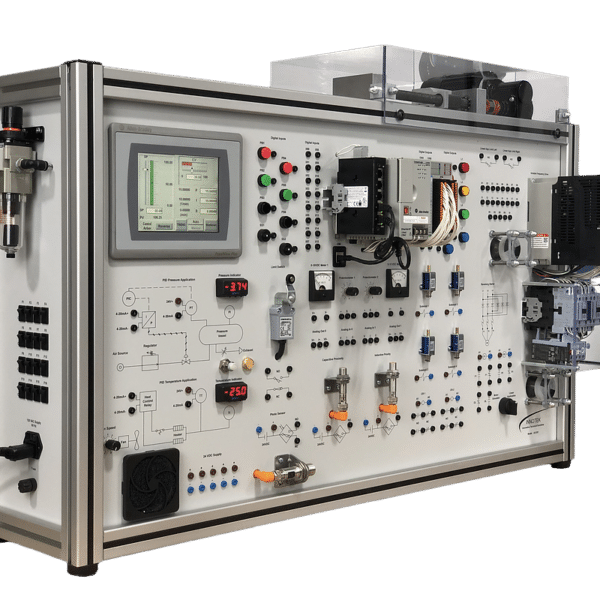

PLC Automation Training System | all-in-one

The ATS-200 Automation Training System provides students with a hardware platform for performing hands-on skills development activities for automation technologies operations. The tabletop or mobile platform includes various applications which can be quickly connected to provide advanced activities, expanding the learning objectives beyond simple on/off functionality.

The all-in-one PLC Training System includes:

◉ Operator Control Application

◉ Sensors and Switches Application

◉ Pneumatic Actuator/Valve Application

◉ Linear Ball Screw Application

◉ BCD Thumbwheel and 7 Segment Display

◉ Dual Analog Potentiometer and Meters

◉ Motor Control Application

◉ Variable Speed Drive (Any Brand)

◉ PLC (Any Brand)

◉ HMI (Any Brand)

◉ PID Pressure Application

◉ PID Temperature Application

The system shown as tabletop trainer with banana jack connections. The unit can be purchased with a mobile frame with all components pre-wired to the PLC requiring no additional connections.

-

Tabletop Wiring Training System

The compact, tabletop EW-101 Electrical Wiring Training System allows for hands-on student lab activities in wiring residential, commercial/industrial, HVAC, and low-voltage systems (fire alarm, security system, etc) circuits.

The double-sided, hands-on training system gives students safe and approachable access to wire various circuits and devices commonly found in real world settings.

Customize your system by choosing your training focus (two per training system):

-

Lock-Out Tag-Out Training System

The Innotek Lockout-Tagout Training system provides learners with hardware allowing for demonstration and assessment of LOTO procedures. Lock-Out Tag-Out trainer puts students in the front seat of proper safety procedures in industrial workplaces.

According to the Occupational Safety and Health Administration (OSHA), lock-out/tag-out is one of the Top 10 “”Most Serious Violations”” and “”Most Often Cited Violations”” in industrial workplaces. LOTO must be taken seriously, as lives could be at stake. Workers maintaining equipment can be seriously injured from the unexpected energization of, release of stored energy from, or startup of equipment.

Proper Lock-Out Tag-Out procedures establish standards for the shutdown of equipment, so that energy sources can be isolated to prevent the release of potentially-hazardous energy during routine maintenance activities. Following proper LOTO procedures helps workers to avoid preventable workplace accidents and injuries.

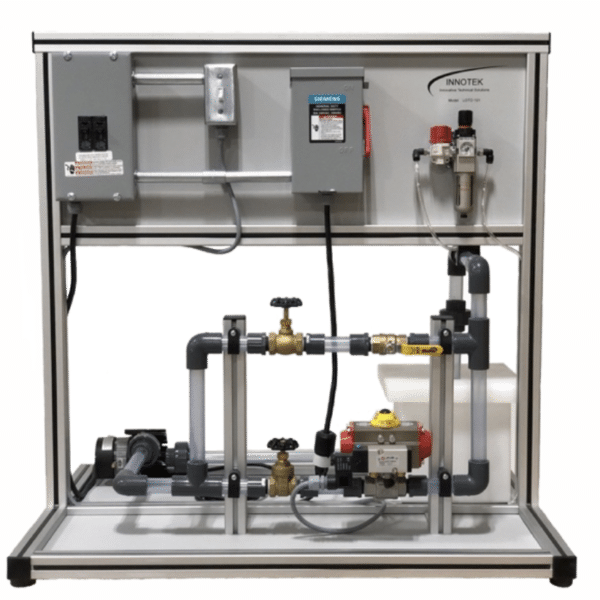

The LOTO-101 training system is a functional system and operates a pump/tank circuit with various power sources and valves for multiple training scenarios. All required safety devices are included with the system for both electrical and mechanical devices.

-

Transformer Training System

We are proud to offer 2 different models of the Transformer Training System:

TRX-101: Fundamental Transformer Training System

TRX-201: Transformer Training System

Both Transformer Training System models provide participants with the necessary hardware for students to learn through hands-on experiments in transformer connections and operation.