Process Control

Process Control is the ability to monitor and adjust a process to produce a desired output. This may pertain to Advanced Manufacturing industries, Oil and Gas, Instrumentation, Food and Beverage Processing, and More.

TOOLKIT’s Process Control training systems are designed to industrial standards to train students for future careers in these fields, and are complete with simulations, SCADA software and digital solutions to fit your classroom’s industry training needs.

Students will learn skills in monitoring and controlling Process Control such as Pressure, Level, Flow, and Temperature.

Showing all 10 results

-

Tabletop Process Control Trainer

We’ve taken our Process Control Training System to a whole new level with the introduction of our tabletop and suitcase Process Control trainer from Innotek. Featuring all features of the IPT-200, the tabletop trainer is capable of teaching Pressure, Level, and Flow variables in a straight-forward, intuitive, and easy to understand way.

The hands-on tabletop process control trainer can be connected to the SMC PLC Training System for expanded controls and instrumentation, or connected to the standard process suitcase for PID control.

-

SMC Process Control and Instrumentation Training System

The SMC IPT-200 Process Control and Instrumentation Training System allows students to perform hands-on experiments in important concepts related to Pressure, Flow and Level applications. All components are entirely industrial to reflect future student experiences in the field.

The system is delivered in a mobile frame version and allows to include several add-ons, including concepts and technologies related to Temperature.

-

SMC Automated Process Control Training System

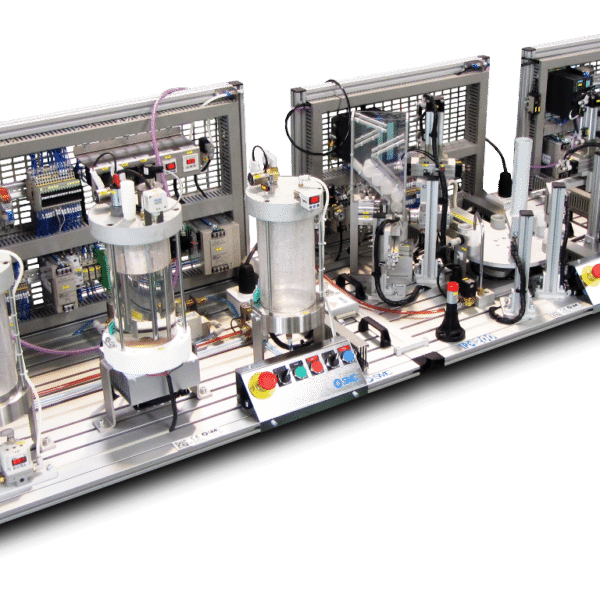

The IPC-200 is SMC’s unique training solution specific to automation and process control. Commonly used for training in the food & beverage production and processing industries as well as pharmaceutical industry, the IPC-200 brings real-world industrial skills and technologies to students’ fingertips with an exciting and project-based tabletop training system.

A fully modular and flexible automate process control system, the IPC-200 is comprised of three modules which can work individually or as a complete process line. Various configurations can be created to adapt the IPC-200 equipment to our users different requirements and budgets.

IPC-200 emulates a liquid production and bottling plant and includes the technologies used in a continuous process industry, such as pneumatics, electric motors, sensors, continuous processes, programmable controllers, industrial communications, etc.

It is built entirely from industrial materials so that student works with the same elements found in the working environment.

-

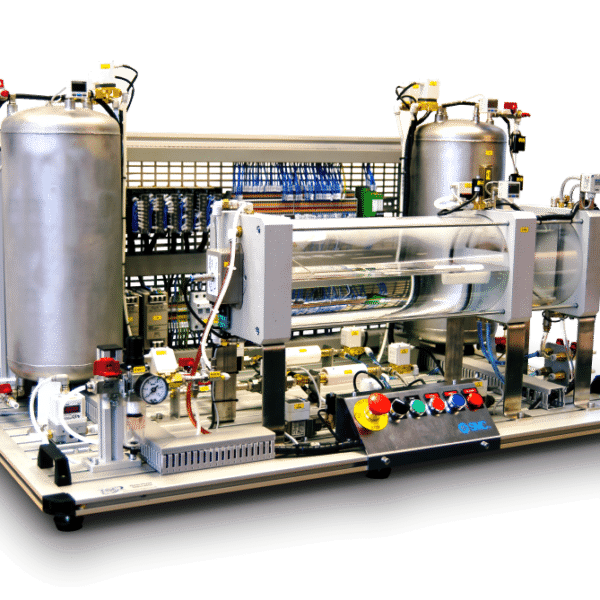

SMC Three-Phase Separator

The new 3-Phase Separator Training System from SMC emulates the industrial separation process of the oil, gas and water obtained from oil wells during the oil production process. The process is performed with all gaseous and liquid components in a pressurized container.

A Three Phase Separator for oil production is a large container designed to separate the fluids obtained from the well into its individual constituent components: oil, gas and water. These types of separators are based on the principle that the three components have different densities. This allows separating them when they move slowly, the gas in the upper part, the water in the bottom and the oil in the middle.

SMC’s new 3-Phase Separator Training System includes all hardware, software, and learning content for effective training in process control and three-phase separation concepts.

-

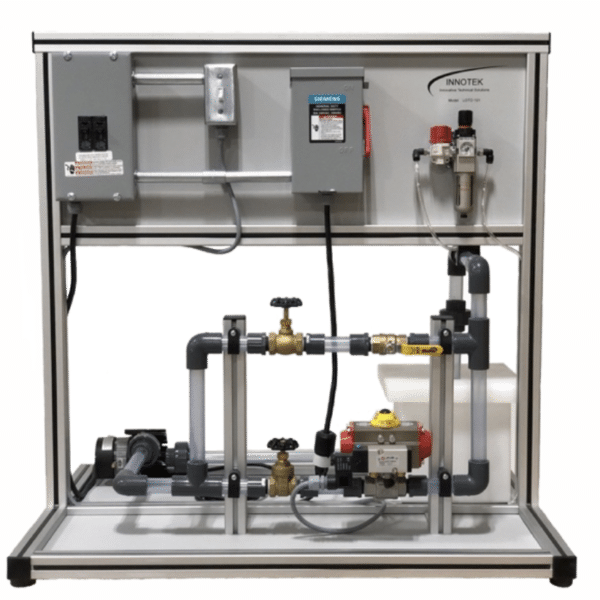

Lock-Out Tag-Out Training System

The Innotek Lockout-Tagout Training system provides learners with hardware allowing for demonstration and assessment of LOTO procedures. Lock-Out Tag-Out trainer puts students in the front seat of proper safety procedures in industrial workplaces.

According to the Occupational Safety and Health Administration (OSHA), lock-out/tag-out is one of the Top 10 “”Most Serious Violations”” and “”Most Often Cited Violations”” in industrial workplaces. LOTO must be taken seriously, as lives could be at stake. Workers maintaining equipment can be seriously injured from the unexpected energization of, release of stored energy from, or startup of equipment.

Proper Lock-Out Tag-Out procedures establish standards for the shutdown of equipment, so that energy sources can be isolated to prevent the release of potentially-hazardous energy during routine maintenance activities. Following proper LOTO procedures helps workers to avoid preventable workplace accidents and injuries.

The LOTO-101 training system is a functional system and operates a pump/tank circuit with various power sources and valves for multiple training scenarios. All required safety devices are included with the system for both electrical and mechanical devices.

-

Pumps Training System

The Pumps Training System provides a hardware solution for hands-on training and study in the topic area of pumps and pump characteristics. Students learn how to operate, install, maintain, troubleshoot, analyze performance, and select centrifugal pumps.

The PUMP-200 training system teaches skills related to commonly used pumps in industrial applications, such as centrifugal pumps, which are used in almost every industry to transfer non-hydraulic fluids of various types from one place to another.

-

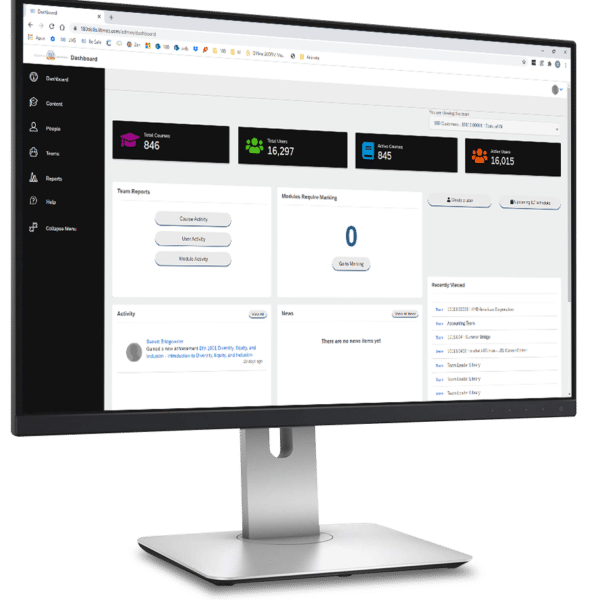

CTE + Workforce eLearning

Toolkit is proud to partner with Valor, 180 Skills, and SMC to bring you the most complete, thorough, and comprehensive eLearning solution for Career and Technical Education. An AWARD-WINNING Learning System for CTE, Workforce Development, and Industry Training.

Web-based eLearning content in over 900 courses – ranging from Career and Technical Education skills, Workforce Development training, Soft Skills development, and more!

Our new eLearning is the most comprehensive skills-based training program out there for real-world skills, certifications, and job-ready outcomes.

Over 600 Technical Skills Courses!

Over 200 Employability and Soft Skills Courses!

Over 80 Quality + Compliance Skills Courses!

-

SMC eLearning

SMC eLEARNING-200 is a flexible, web-based learning platform for skills-based, industry-driven learning to take place anywhere, anytime there is the motivation to learn!

Users can develop skills and theoretical knowledge around Automation and Technical topics such as Robotics, PLCs, Electrical, Pneumatics, Hydraulics, Motors, Sensors and More.

-

SMCTwin-400 Digital Twin Software

We are thrilled to bring the first Digital Twin training software to schools across the globe with SMC’s revolutionary Digital Twin-400 software.

SMCTwin-400 is an online, one-for-one emulation platform where students will be able to develop and control digital twin models. All models operate and behave in the exact manner in which they would in the real world, giving students a never-before-seen lens to view automation and industry.

This true Industry 4.0 software provides students with the ability to access virtual replicas of real SMC training equipment and industrial components, allowing them to safely experience industrial technologies and processes, monitor all of the system’s electrical and pneumatic values, program and create various PLC/HMI programs, and witness the results in real time!

-

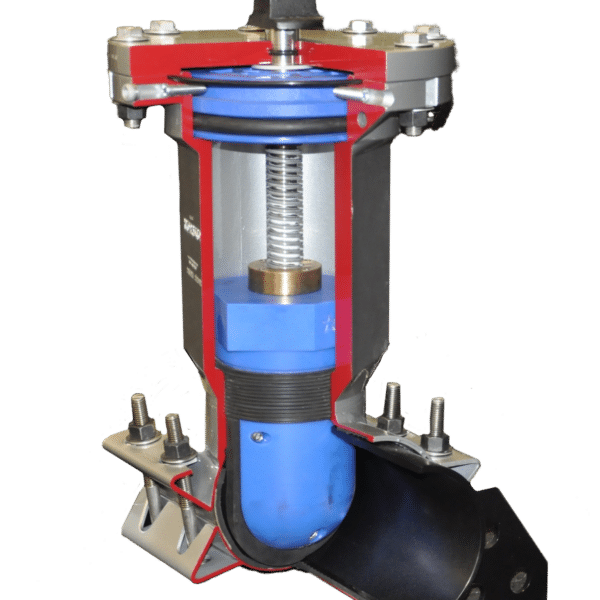

Cutaway Training Models

At Toolkit Technologies, we only bring the very best training aids, training systems, and industrial-quality technologies into the classroom. So for applications where you want to see, show, and demonstrate the inner workings of an object, look no further than our Custom Cutaway Creations.

We can create a visually intriguing cutaway display that will reveal the inner workings of any mechanical or electro-mechanical product. From concept to completion, we can make it happen. Our experience and expertise allows us to deliver the perfect training aid cutaway for your program. Or simply tell us what you’re looking for, and we’ll make it happen.