Description

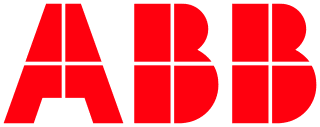

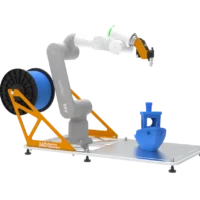

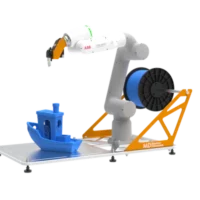

This 3D printing cell is a powerful solution that uses the ABB GoFa and Massive Dimension’s filament extruder. This solution is ideal for colleges and universities as it includes comprehensive course materials and globally recognized STEM certification.

Six-axis printing, simplified

This cell is designed with ease of use in mind, eliminating barriers for users looking to move into the future of fused deposition modeling with six-axis motion*. In a compact, lightweight package, the printing cell is easy to transport and deploy and can run on single-phase, low-voltage electrical supplies.

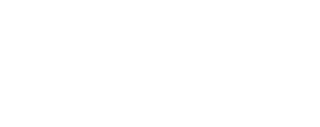

ABB’s printing software for RobotStudio (which is donated to schools) enables users to go from CAD model to toolpath in thirty minutes or less.

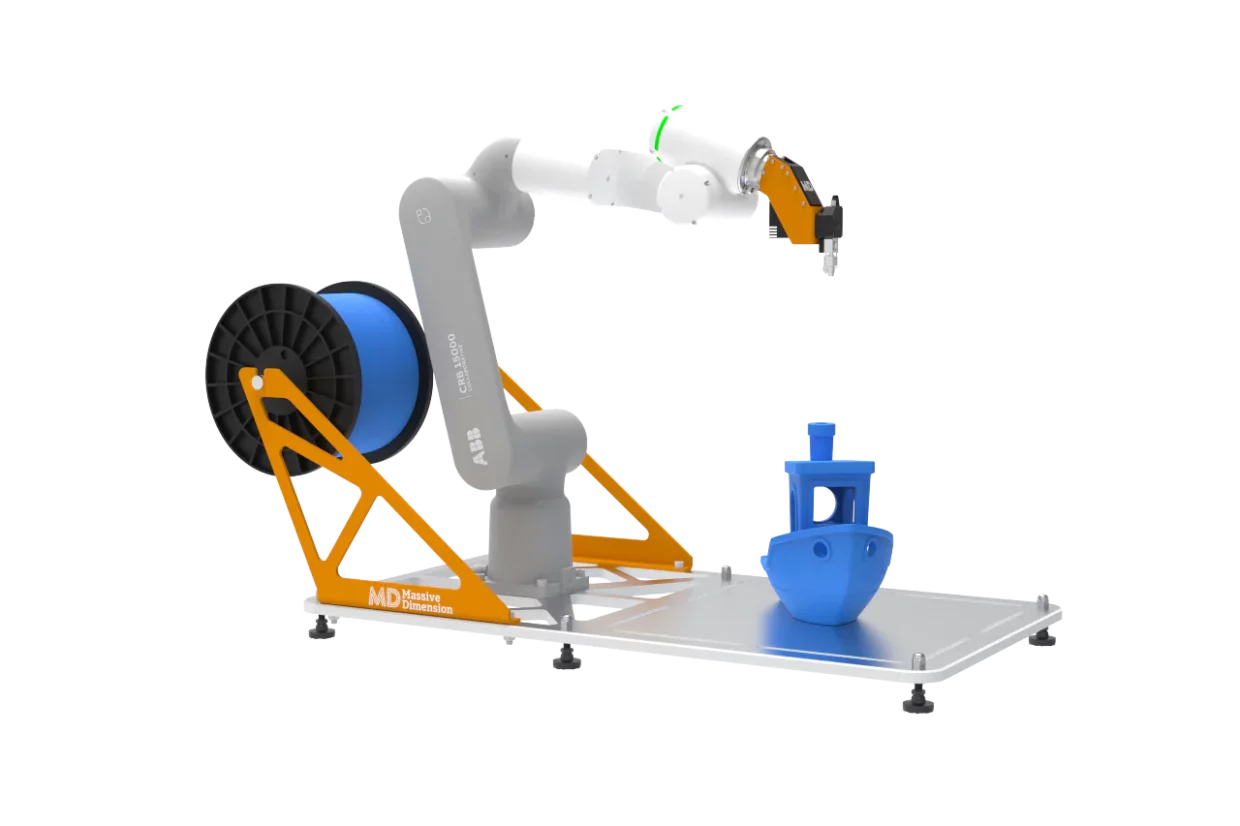

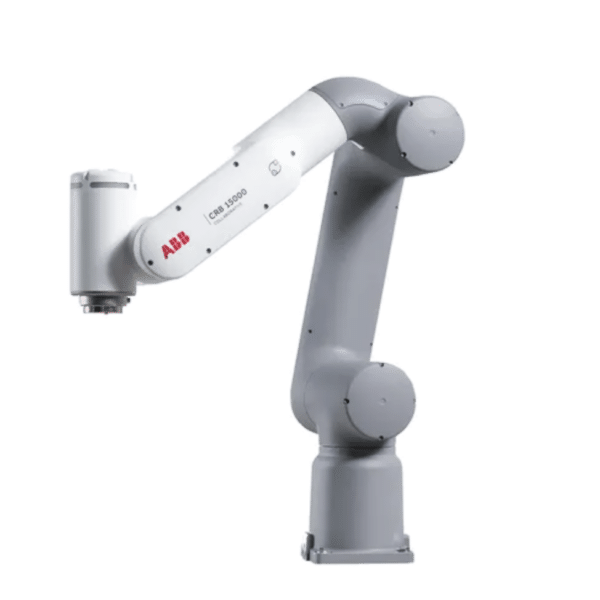

A robot that is strong, yet safe

The GoFa CRB 15000 robot from ABB is designed to handle payloads up to 5kg. It has integrated torque sensors in each of its six joints, offering superior power and force-limiting performance. Together, these bring GoFa to an immediate stop if it senses any contact with an object, and making it perfect for educational settings and environments.

Easy set-up and Operation

Set-up and configuration is easy with intuitive, graphical Apps directly on the FlexPendant. With the 3D Printing Powerpac add-in for RobotStudio, converting print files from your preferred slicer into RAPID modules is simple and straightforward.

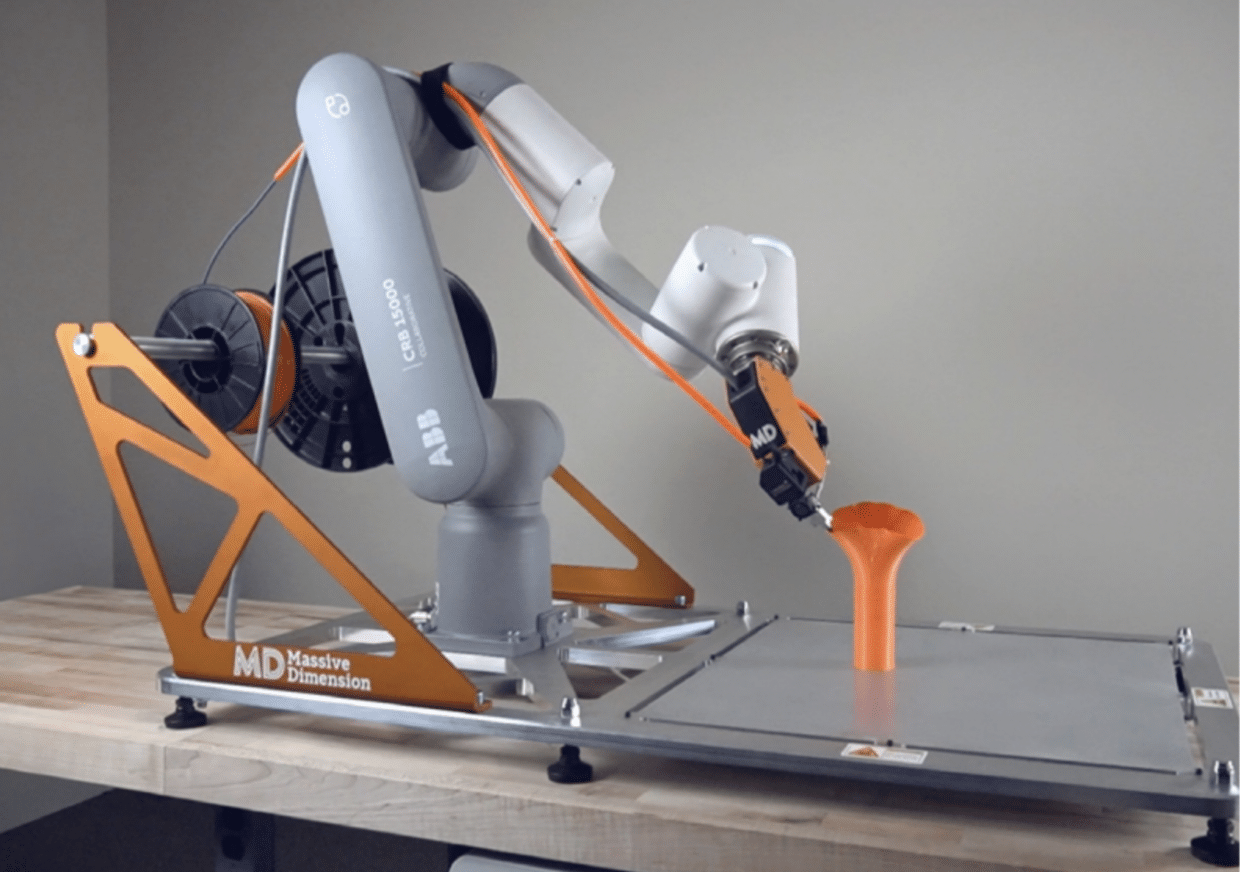

Compact and mobile

The entire MDAC1 assembly is built on an industrial strength protective frame with an integrated heated build plate and can be easily mounted on a tabletop or cart. Rugged leveling feet ensure that you can place it where you want it and get to production.

Key Features

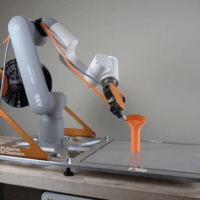

Filament Extruder – The filament extruder on the MDAC1 is compatible

with any 1.75mm filament and can be configured with nozzle sizes from 0.4mm to 1.2mm. Nozzle changes are quick and easy, as is switching materials. The extruder is direct-drive, eliminating troublesome jams more common with Bowden configurations.

Massive Build Volume – The MDAC1 allows you to break into the world of large-format printing with a 21.5in x 21.5in x 20in

build volume.

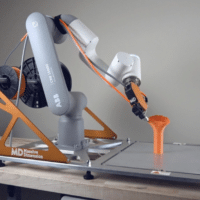

Go far beyond XYZ

Thanks to the additional degrees of freedom granted by a six-axis robot, the MDAC1 allows slicing strategies beyond the traditional horizontal deposition of gantry-based printers. Explore non- planar, multi-planar, and angled printing as solutions to the limitations of conventional printing, such as unsupported overhangs, or to improve surface finish and mechanical strength.

Standard Equipment

• ABB GoFa CRB 15000

• Massive Dimension Process Cabinet

• Massive Dimension Filament Extruder

• All-Metal Hot End

• Heated Build Surface

• 1 kg spool of PLA Filament

• 100 free RobotStudio licenses

Additional Options Available for Purchase

• Curriculum materials and globally recognized STEM certification for teachers/students

• Safety panels

• 1yr Adaxis 6-axis slicing software