Manufacturing

Showing 13–24 of 67 results

-

Hand Tools Fundamentals Training Bench

TOOLKIT’s Hand Tools Fundamentals Training System is a versatile foundational training package key to careers in the modern Construction industry.

Paired with hands-on lab activities, this courseware will help to teach students fundamental concepts in measurement, cutting, power tools, fasteners, hand tools, material handling, workplace and soft skills, etc.

The optional workbench provides additional storage capabilities and doubles as a student activity platform.

-

SMC Mechanical Training System

The SMC MEC-200 Mechanical Training system provides participants with hardware allowing for hands-on experiments in the use, troubleshooting, installation, and maintenance of mechanical drive technologies.

Topic coverage includes mechanical shaft alignment, pulley alignment, belt installation, sprocket alignment, chain installation, gear alignment practices and speed ratios, and is all based around practical, real-world activities and tasks.

Learners will practice industry-driven hands-on skills such as leveling an electric motor, calculating mechanical efficiency, installation of jaw couplings, and installation and alignment of a sleeve coupling and shaft, and more.

-

SMC Basic ACDC Electrical Training System (AC, DC, Solid State)

The SMC BEMATE-200 – Your Basic Electricity Mate – provides hardware for hands-on activities and the study of DC, AC and Solid State fundamentals. All devices are permanently mounted and can be quickly connected in a variety of configurations via Banana Jack connectors.

Users will be introduced to the function and use of various devices and circuits. In addition, test equipment and fault insertion activities will allow for development of troubleshooting skills.

-

SMC Smart Sensors Training System

The SMC SENSOTRAINER-200 is the sensor technology trainer that allows students to learn the different sensors used in industry, such as inductive, capacitive, optical, and fiber optics.

The SENSOTRAINER-200 training system is a platform for exploratory exercises in the topic of digital, analog and smart sensor technologies – all commonly found in various industrial settings. The system easily connects to the SMC PLC Training System for expanded learning.

This system offers an easy connection and flexibility for changing position and orientation in order to explore how the signal is performing.

-

SMC Pneumatics Training System

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed the most state-of-the-art and robust training system for teaching Pneumatics and Electro-Pneumatics Fundamentals to schools, training centers, and colleges. All components are industrial, used by companies around the world, so you can rest assured that your pneumatics learning directly translates to on-the-job relevance.

The Pneutrainer-400 comes with modular design that allows several customizable options to suite your training needs. Choose you form factor (mobile cart or tabletop), single or double-sided, and choose your training package!

SMC Pneumatics training systems are complete with interactive lesson plans, curriculum, user activities, eLearning and simulation software for the world’s most complete and comprehensive Pneumatics training platforms.

-

SMC Transparent Hydraulics Training System

A true, one-of-a-kind training system from SMC! The HYDROMODEL-200 meets industrial training needs related to Hydraulics in a very visual way.

All hydraulics components are made up of a transparent methacrylate body with internal industrial metal hydraulic parts. This allows students to see inside the hydraulics components as they operate and actually see the hydraulic fluid moving. No Hydraulics Training System in the world does for student understanding of Hydraulic Theory what the Hydromodel-200 does in a simple, visual way.

-

SMC Hydraulics Training System

Hydraulic drives continue to be used in numerous applications in automated industry. With the SMC HYDROTRAINER-200 you will be able to meet all of your training requirements in the technology related to these drives.

From Basic Hydraulics to Electro-Hydraulics to Proportional Hydraulics, SMC’s Industry-leading Hydraulics Training System is designed to fit your very needs along with the training needs of your local area industries. Designed using top-quality industrial components in an ergonomic classroom training cart or tabletop form, the Hydrotrainer-200 has everything required in order to get real-world skills and start working from the very first day.

Use in conjunction with SMC eLearning and SMC’s autoSIM-200 simulation software for holistic hands-on training AND engaging and interactive virtual training.

-

Compact Pneumatics Training System

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed this low-cost, yet robust, tabletop pneumatics and electro-pneumatics training system featuring all industrial components. The versatile Pneumate-200 training system is “your classroom pneumatics training mate!” that provides practical hands-on training activities in the areas of Pneumatics, Electro-pneumatics and Pneumatic Applications.

-

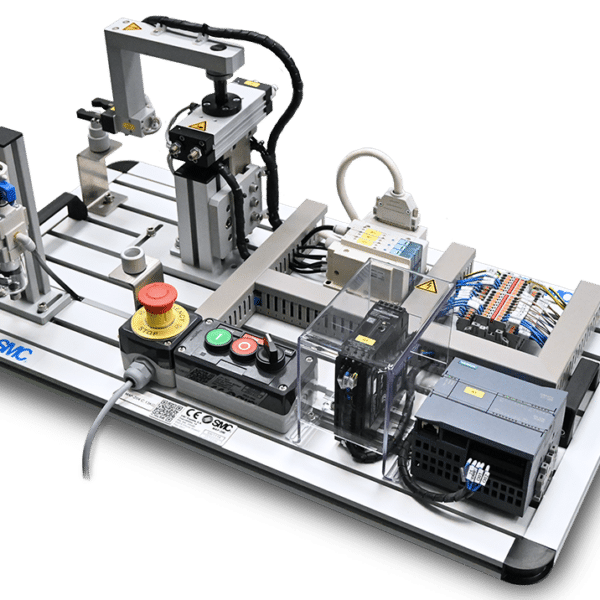

Part Feeding and Detecting Training System – MAP-201

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-201: Body Supply Part Feeder + Detector/Ejector

The process: A gravity feeder houses the parts in a column. Each part has a non-symmetrical interior housing and is ejected by a pneumatic cylinder. The correct orientation of the part is verified using a cylinder with a plunger. After verification, an oval section pneumatic cylinder moves the work-piece to the final position. Otherwise, a single acting cylinder removes the part via the evacuation ramp.

-

Vacuum-Held Material Handling Training System – MAP-202

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

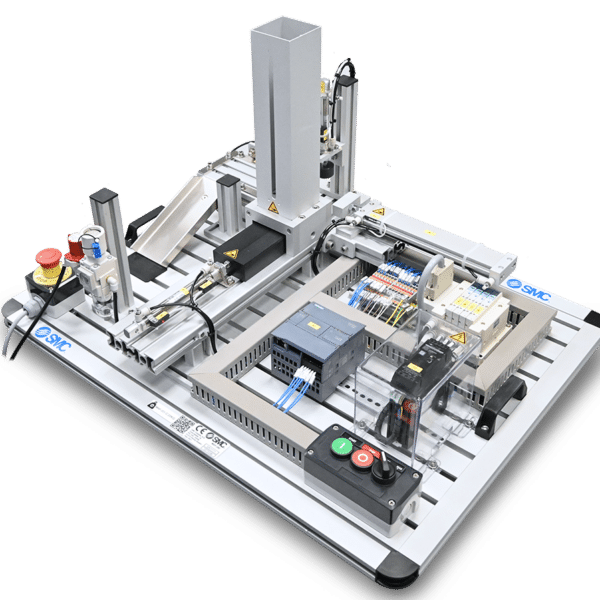

MAP-202: Vacuum-Held Handling Device with Two Shafts

MAP-202: The function of this handling device is to transfer the part from a starting area to a final unloading area, using three vacuum pads. This is a cartesian handling device with two shafts which moves a part from one position to another, holding it with a set of three vacuum pads.

-

Vertical Revolving Material Handling Training System – MAP-203

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

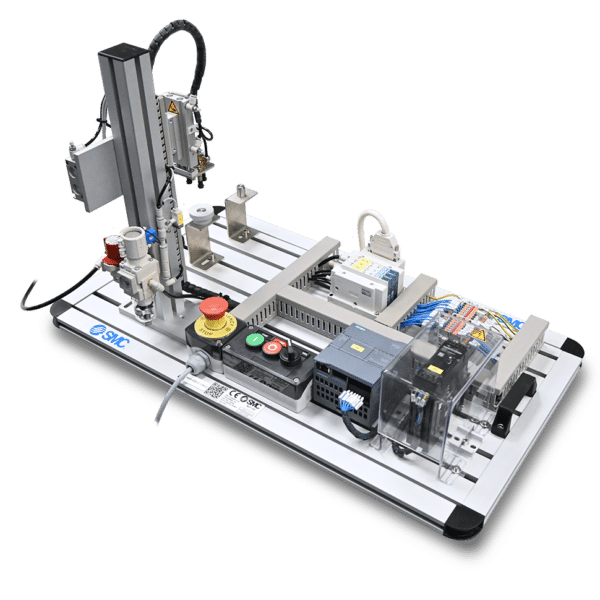

MAP-203: Vertical Revolving Handling Training System with Internal Gripper

The function of this material handling device is to transfer the part from a starting area to an unloading area, using an internal gripper. The part used in this process is a bearing so that when it is placed on the unloading area, it fits perfectly onto a stainless steel pivot with a slightly smaller diameter than the bearing’s inner diameter.

-

Horizontal Rotolinear Material Handling Training System – MAP-204

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

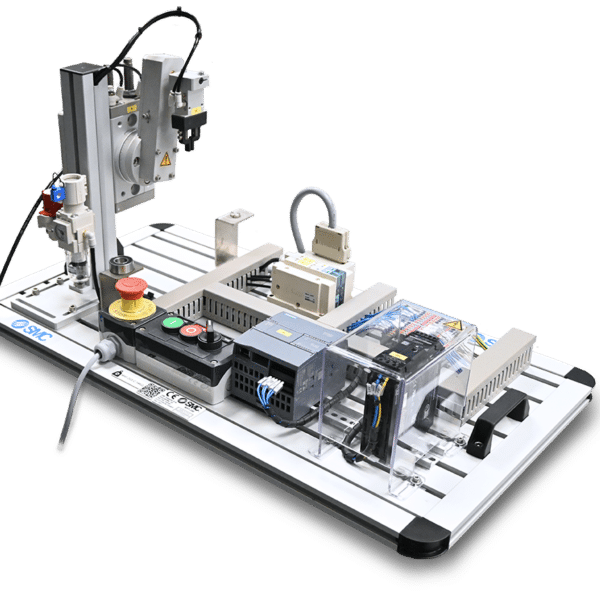

MAP-204: Vertical Revolving Handling Training System with Internal Gripper

The function of the handling device is to transfer the part from a starting area to an unloading area through a rotolinear actuator that displaces an outer gripper. The part being transported is a metal bearing.

The part used is made from anodized aluminum, 14.6mm diameter and 41mm height, so that when the part is placed on the unloading area it fits perfectly onto a stainless steel pivot with a slightly larger diameter than the shaft.