Description

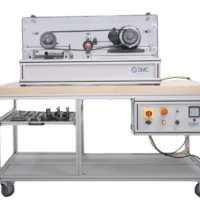

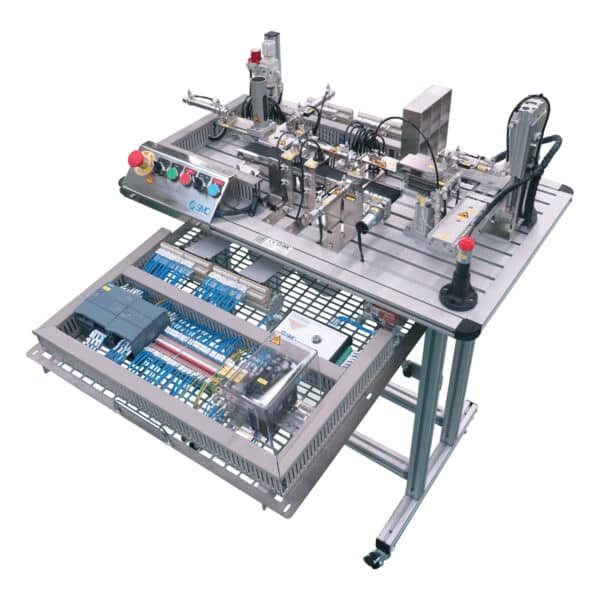

The SMC Mechanical Training system provides participants with hardware allowing for hands-on experiments in the use, troubleshooting, installation, and maintenance of mechanical drive technologies. Topic coverage includes mechanical shaft alignment, pulley alignment, belt installation, sprocket alignment, chain installation, gear alignment practices and speed ratios, and is all based around practical, real-world activities and tasks.

Our sleek, maple top workbench, under-mounted variable speed drive and electrical disconnect with integrated component drawers keeps all tools and components easily accessible and safely stored.

System includes: Shafts, Bearings, Pulleys, Belts, Sprockets, Chain, Torque Plate, Motor, Motor Tensioning Base, Chain and Belt Tensioning Idler.

Mechanical TOPIC Coverage

- – Mechanical Concepts

- – Fasteners

- – Measurement Devices

- – Belt Drives

- – Chain Drives

- – Gear Drives

- – Speed Ratios

- – Shaft Alignment

- – Torque Patterns

MEC-210: BELT DRIVE TRAINING SYSTEM

The configuration of the trainer as a belt-driven training system consists of the use of a power transmission system, which uses a combination of pulleys and belts to transmit mechanical power between shafts. The rotational force is transmitted to a drive shaft through the use of an electric motor. So that this mechanical rotational force can be distributed to the rest of the components assembled in the trainer.

This application allows students to explore and analyze the installation, alignment, tension and speed relationships associated with belt drives.

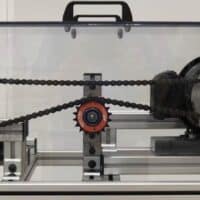

MEC-220: CHAIN DRIVE TRAINING SYSTEM

The configuration of the trainer as a chain drive training system involves the use of a power transmission system, which uses a combination of sprockets and chains to transmit mechanical power between shafts. The rotational force is transmitted to a drive shaft, which contains a sprocket, through the use of an electric motor. This mechanical rotational force can then be distributed to the rest of the components assembled in the trainer.

This application allows students to explore and analyze the installation, alignment, tension and speed relationships associated with chain drives.

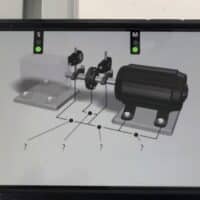

MEC-230: GEAR TRANSMISSION TRAINING SYSTEM

The configuration of the trainer as a gear-driven training system consists of the use of a power transmission system, which uses a combination of gears to transmit mechanical power between shafts. The rotational force is transmitted to a drive shaft, which contains a gear wheel, through the use of an electric motor. So that this mechanical rotational force can be distributed to the rest of the components assembled in the trainer.

It allows students to explore and analyze the installation, alignment, gearing, backlash measurement and speed ratios associated with gears.

MEC-240: BEARING INSTALLATION TRAINING SYSTEM

The trainer configuration as a bearing installation system consists of a separate bearing training unit. This unit can be mounted in the frame of other mechanical configurations or can be mounted directly on a workbench.

This application allows students to explore and analyze the installation, removal and adjustment considerations associated with bearing applications.

MEC-250: SHAFT ALIGNMENT TRAINING SYSTEM

The configuration of the trainer as a training system for shaft alignment consists of the use of an alignment and coupling system between shafts to enable the transmission of mechanical power. The rotational force is transmitted to a drive shaft, which incorporates a coupler at its free end, through the use of an electric motor. In such a way that this mechanical rotational force can be distributed to the rest of the components assembled in the trainer.

This application allows students to explore and analyze shaft coupling and alignment methods for mechanical transmission systems.