Industry 4.0

Showing 1–12 of 29 results

-

Niryo 6-Axis Training Robot

Discover our Niryo tabletop 6-axis robots for training, education, and research.

The first 6 axis desktop robotic arm inspired by industry 5.0 – Start Training for the Future Today!

The Niryo Ned2 is an educative solution for everyone who wants to teach or learn through robotics.

The robot is inspired by industry, and includes robust curriculum, manuals and activities for all levels of learners to get practical career and technical education training.

-

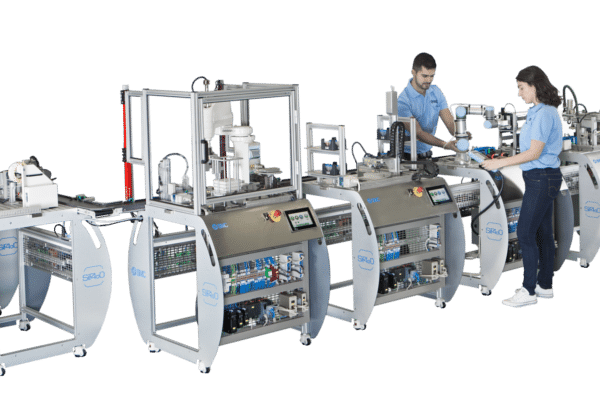

SMC Smart Innovative Factory Training System

Take a look at the most remarkable, fully-connected Industry 4.0 Training Platform on the market for hands-on training, exploration, and research in advanced manufacturing industries: SMC’s SIF-400.

SMC’s Industry 4.0 Smart Innovative Factory reproduces an industrial, cyber-physical smart factory – in both production applications and supply chain applications – for a school to provide real-world advanced manufacturing training. The training system is a modular design comprised of 14 interconnected stations for hands-on training and research of connected systems, operational data and data analytics, IIoT, predictive and preventative maintenance, management execution software (MES), inventory tracking and control, cybersecurity, and more.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

SMC Mechatronics + Industry 4.0 Learning System (M&I-400)

The newest training system for developing skills in both Mechatronics and Industry 4.0 technologies.

SMC’s M&I-400 is a learning system designed for training on industrial technologies in mechatronics and industry 4.0, while being incredibly attractive and visually appealing. The industrial system makes it easy for students to attain industry’s most needed skills through exciting and practical activities, while also attracting students to learn these skills and technologies.

Projects and activities can be carried out that motivate students to explore Industry 4.0 concepts and technologies while also learning important fundamental concepts related to Mechatronics.

SMC’s M&I-400 emulates a highly automated factory, where different types of products are produced, packed and shipped. The M&I-400 training system makes it possible to work on advanced and connected manufacturing concepts.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

SMC Flexible Manufacturing System – Industry 4.0

The best just got better with this incredible training from SMC! SMC’s FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market for mechatronics and industrial troubleshooting training and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training.

The SMC Flexible Manufacturing System is used by countless companies and schools across the globe for real industry training.

-

Highly Automated Training System HAS-200

Train your students with the same Industry 4.0 training system used by companies like Intel and Boeing for their workforce training!

The HAS-200 SE i4o brings SMC’s industry leading technologies into a modular, customizable smart factory for education with training options in PLC programming, HMI programming, Management Execution Systems software, interconnected systems, smart devices, robotics, and more.

-

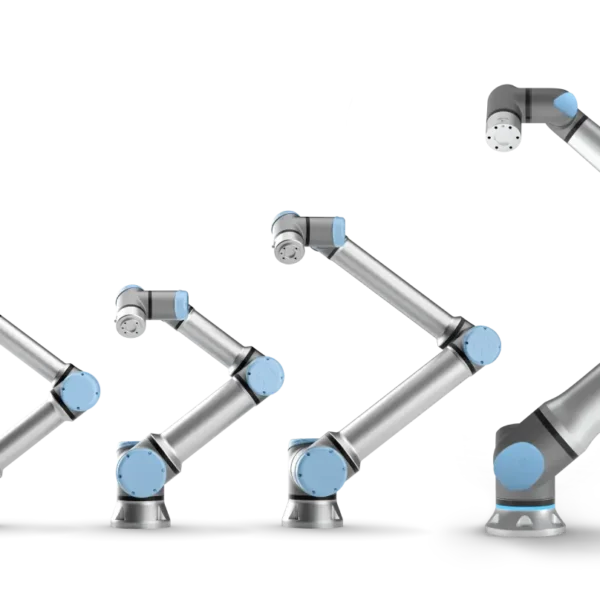

Universal Robots Collaborative Robots

Toolkit Technologies is proud to offer Universal Robots’ industry-leading collaborative robots to education and training institutions around the country.

Empower your students with cutting-edge industrial skills training solutions using Universal Robots’ collaborative robots. Our hands-on training systems, featuring all-industrial technologies sourced from industry leaders like SMC, UR, Miller Electric, and others, immerse learners in real-world applications that prepare them for dynamic careers in today’s tech-driven workforce.

Elevate your educational programs with our state-of-the-art robotics technology, fostering innovation and expertise in your students. Explore our range of training solutions now for comprehensive technical education solutions that drive future success.

We are proud to offer robust curriculum, eLearning, on-site training, and custom training applications with every UR Robot.

Let us know what robotics application you want to teach, and we’ll build it!

-

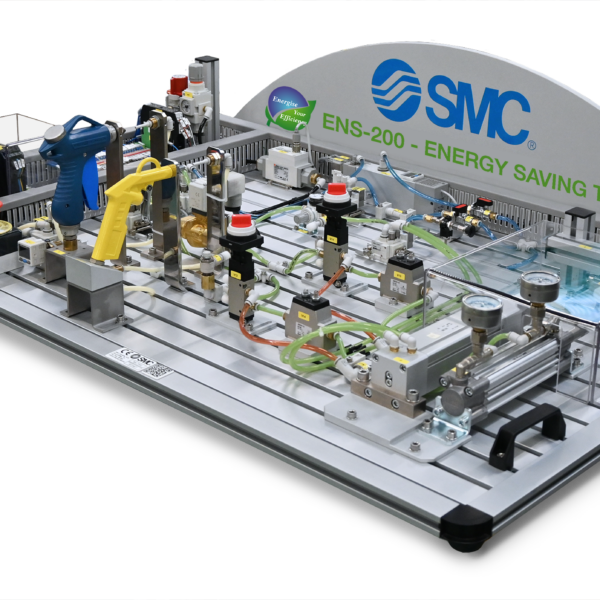

SMC Air Energy Savings Trainer

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed a state-of-the-art training system for teaching students about Sustainability, Energy Efficiency, Green Technologies, and Air Leakage.

The ENS-200 integrates a series of applications (vacuum, actuators and blowing) aimed at getting technicians to understand and implement the proper procedures and standards associated with energy saving in compressed air installations.

Modern Manufacturing needs to be green and companies are adopting these green energy conservation technologies and techniques, so let’s train students to be prepared.

The ENS-200 teaches you how to detect possible excessive consumption and suggest actions to prevent it. Users will analyze different scenarios through a series of guided activities. Each experiment shows how much has been saved, both as a percentage and in the chosen currency.

-

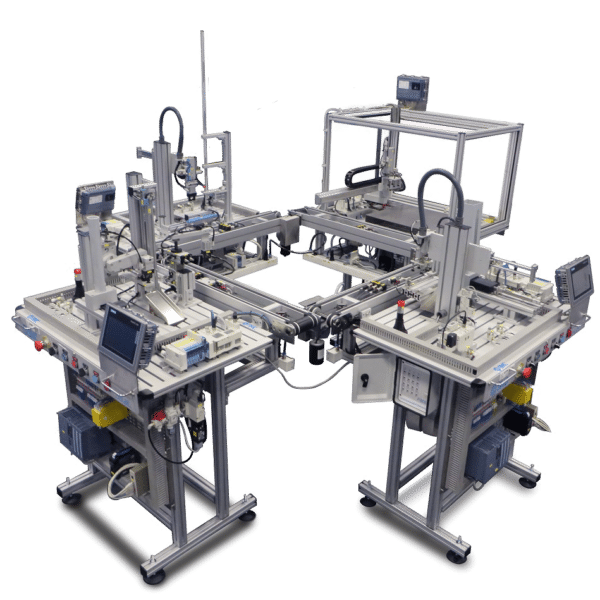

4-Station Flexible Manufacturing System i4o

The best just got better with this incredible training from SMC! The FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training for industry.

The 4-Station Configuration brings classrooms a compact and expandable solution for hands-on Industry 4.0 training with built-in troubleshooting.

Students will get industry-relevant hands-on training around the crucial skills demanded by manufacturing and industry. Industrial manufacturing skills student expect to receive include automation processes, safety, PLC programming, Distributed IO, smart devices, artificial vision, and more!

-

Hirebotics Robotic Welding System

We are proud to represent the #1 robotic welder on the market today in terms of ease-of-use and approachability. Learn why companies across the country are adopting this collaborative robot welding cart in record numbers.

The challenge with implementing robotic welding systems is that rarely can you find expertise in both welding AND robotics. This industrial cobot welding system from Toolkit Technologies and Hirebotics alleviates all hurdles with it’s turn-key, all-in-one system that delivers high quality precision and accuracy, easy-to-use and approachable user interface, and best-in-class results.

Start training the future generation of welders on automation robot welding training carts.

Available with UR10e or UR20 robots.

Available as a Cobot Welder or as a Cobot Plasma Cutter.

-

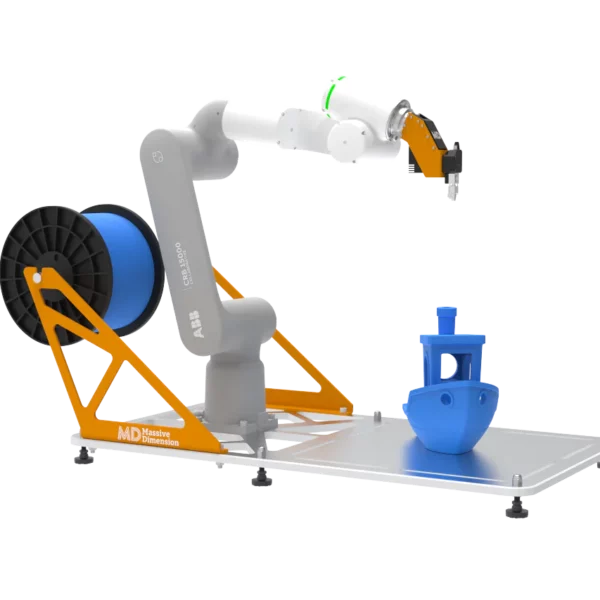

ABB Collaborative Robot 3D Printing

Have you ever wanted to print BIGGER with your classroom 3D printer? Or have you wanted to explore the capabilities of your industrial and collaborative robots?

We are proud to introduce the MDAC1 3D Printing System for Education, the first of its kind classroom robotic 3D printer!

The Collaborative Robot 3D Printing system features a GoFa CRB 15000 cobot and pioneering FDM 3D printing technology from Massive Dimension for unparalleled capabilities and excitement.

Now certified and authenticated by STEM.org!

-

Omron Mobile Robot

The Omron LD Mobile Robot is a self-navigating Autonomous Mobile Robot (AMR) designed for dynamically moving material in challenging environments that may include confined passageways as well as dynamic and peopled locations. Unlike traditional autonomously guided vehicles (AGVs), Omron Mobile Robot requires no facility modifications, such as floor magnets or navigational beacons, saving users deployment costs.

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.