Description

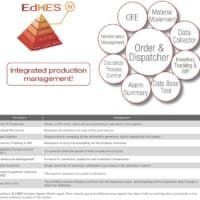

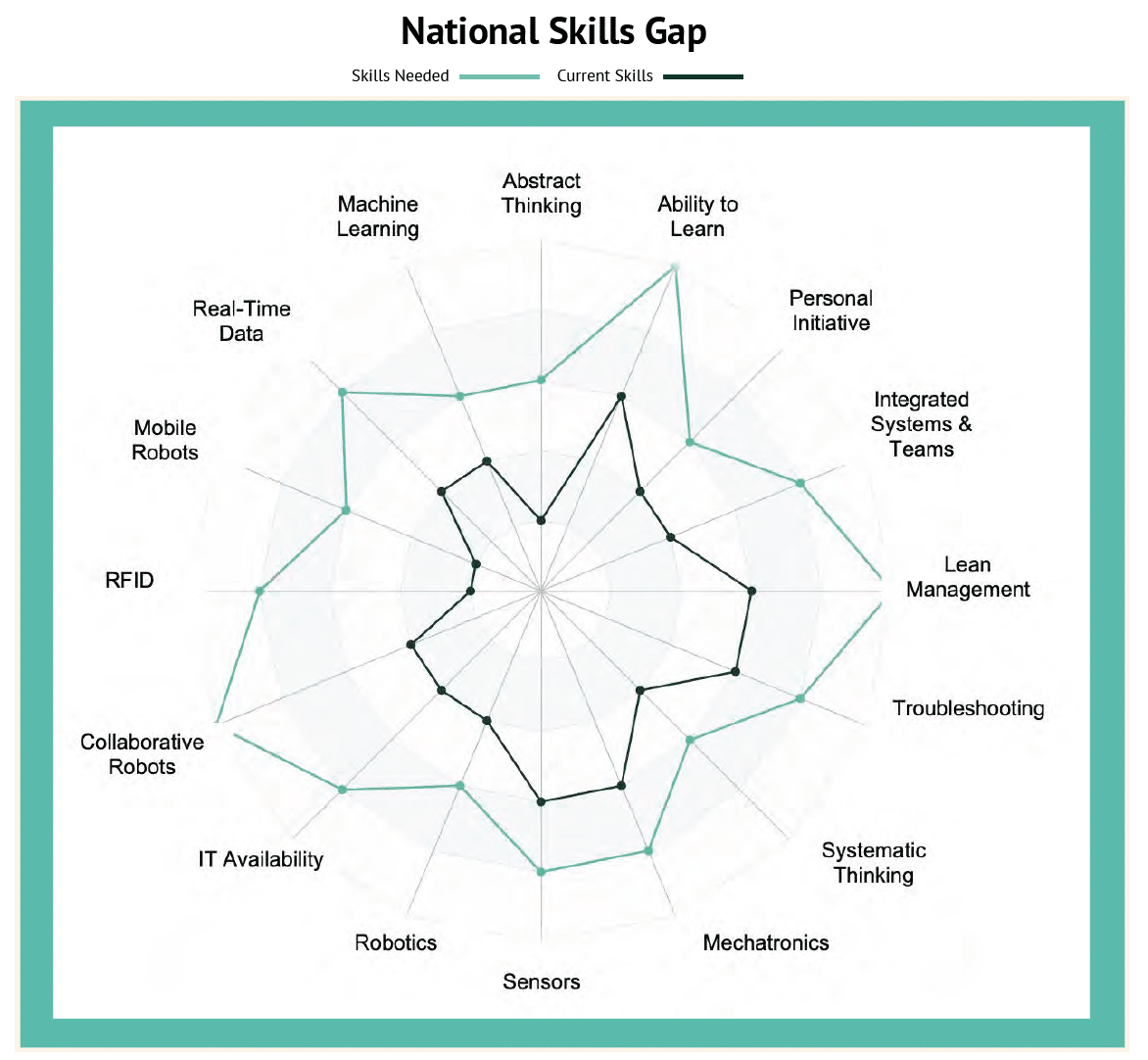

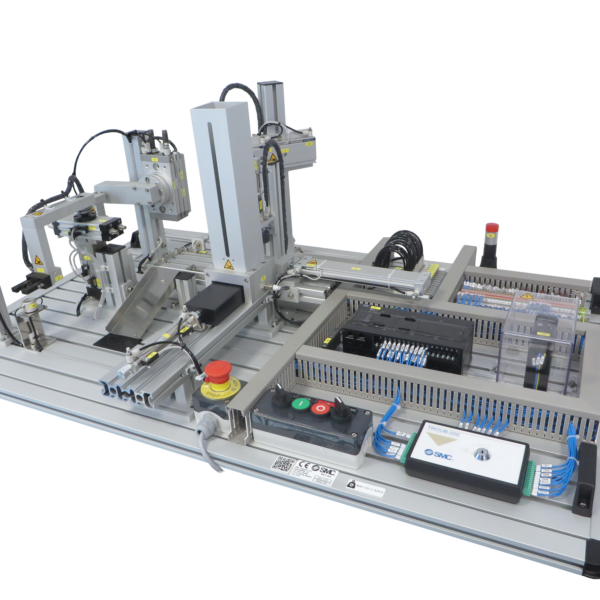

The HAS-200 Special Edition system with more technologies of Industry 4.0 allows the development of the most demanded skills in a highly automated environments of Industry 4.0. This technologically advanced didactic equipment allows the acquisition of the required skills for the different professional sectors.

In addition to the technologies implemented in the standard edition of this system, the special version includes additional technologies that make this equipment the ideal solution to emulate the reality of a smart factory with the latest 4.0 technologies.

THE PRODUCT / PROCESS

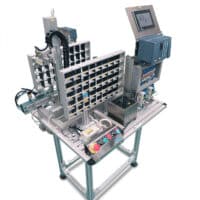

HAS-200 allows the user to manufacture 19 different products. The raw material includes containers with four types of label (red, blue, yellow and multi-colored). Each label incorporates a barcode that allows the product to be identified throughout the process with the BCR readers included in each station. In addition, RFID technology has been added to several stations in the system, as well as a QR code printed on a label of unique content.

Within the process, both the material weight and height is measured. These two variables are stored in the database and allow the generation of historical data, control charts, etc. within the Statistical Process Control (SPC) module.

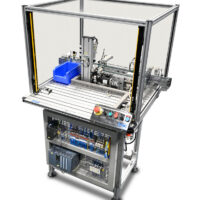

Each of the HAS-200 system stations carries out part of the process.