Description

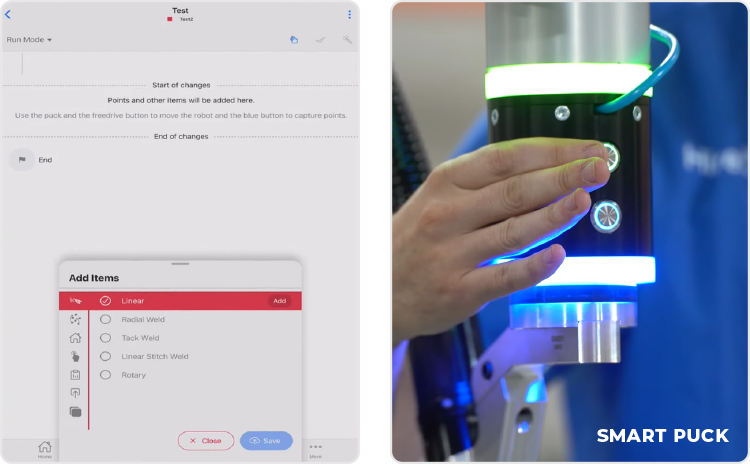

- Easiest Cobot Teaching

- Weld Any Material

- High Quality MIG Welding Robot

- Automate Any Manual Process – Successfully make TIG-quality welds, and improve your manual Stick, and MIG output!

- Instant Service and Support

- Data Tracking and Analytics

- Dry Run vs Torch

Specifications

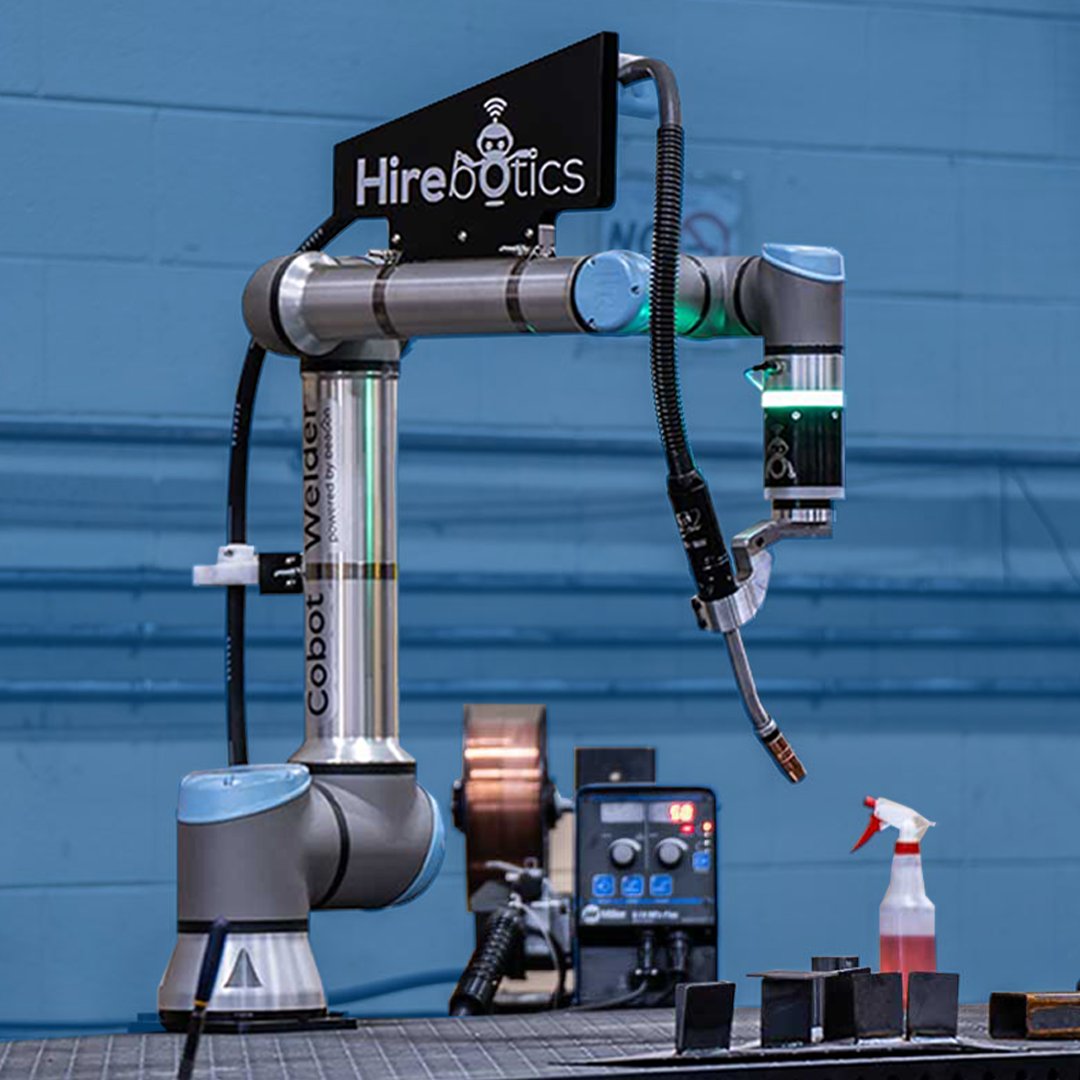

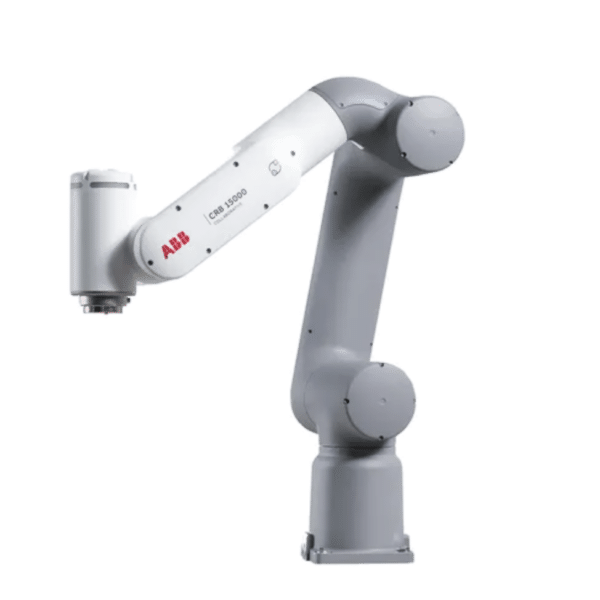

Universal Robots – UR10e – 51″ Reach

Universal Robots – UR20 – 69″ Reach

Welding Power Source

Miller Invision 352MPa with S-74 MPa Plus

208v-575v single or three-phase

350 Amps

Or ESAB available

Welding Torch

- UR10e – Tregaskiss Tough Gun MIG welding gun

- UR20 – Tregaskiss Tough Gun I.C.E. MIG welding gun

Robot Welding Cart

32″ x 48″ Siegmund Assembled Welding Cart with 5/8″ Holes on 2″ Spacing for Flexible Mounting

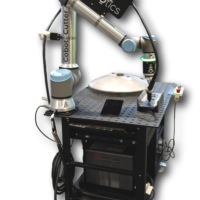

Cobot Plasma Cutting Cart

Take your manufacturing classes to the next level with our Cobot Plasma Cutting System. Perfect for curved, domed, rounded and larger parts that your traditional XY plasma cutter table isn’t optimized for, our Cobot Cutter is the classroom manufacturing tool you need.