Description

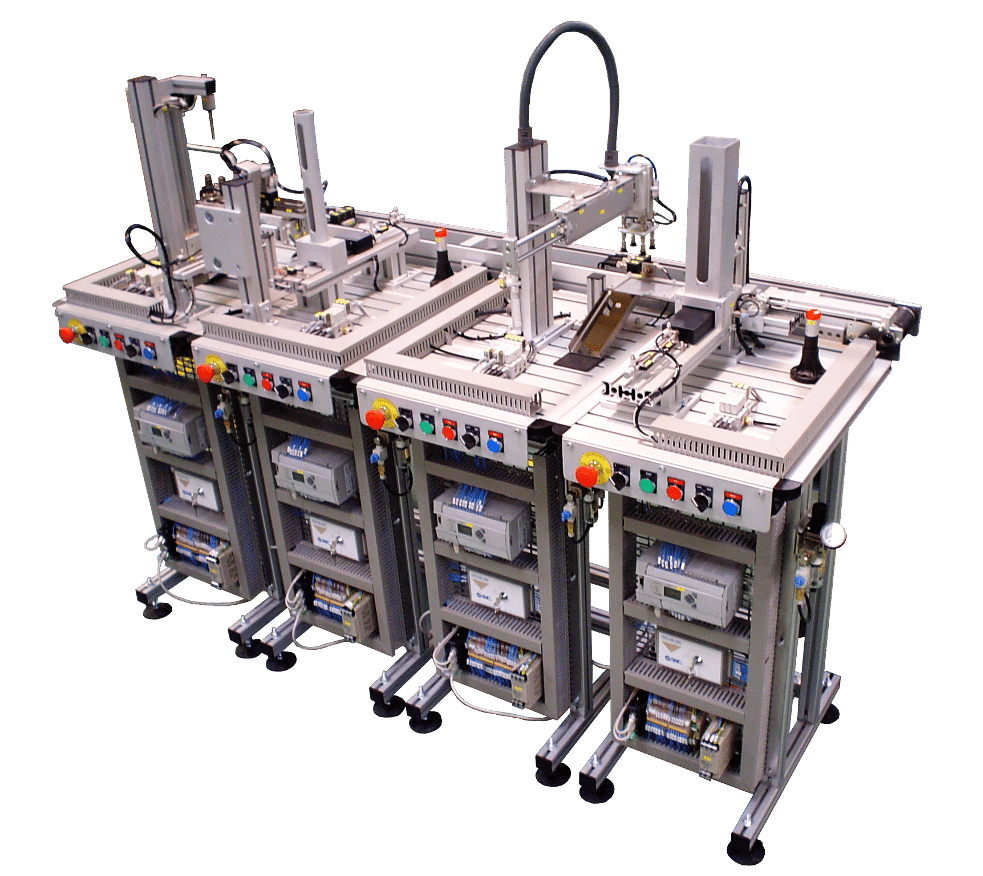

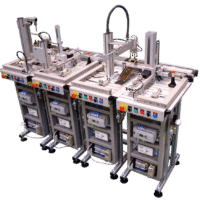

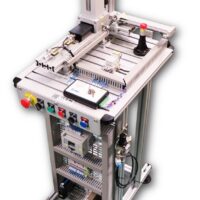

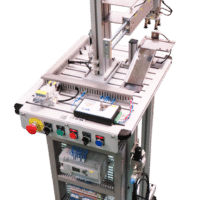

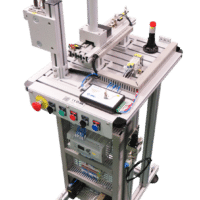

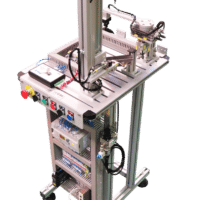

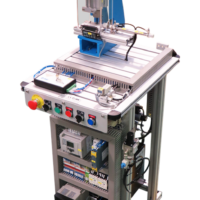

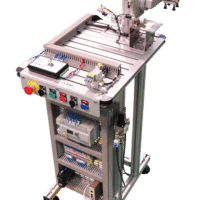

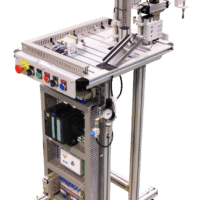

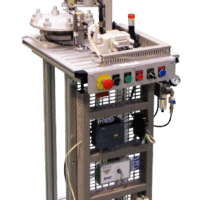

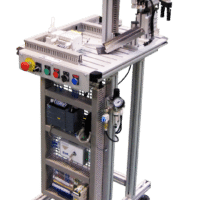

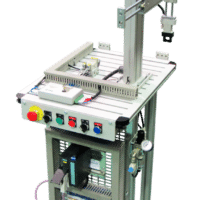

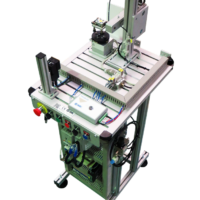

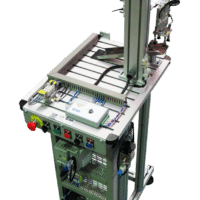

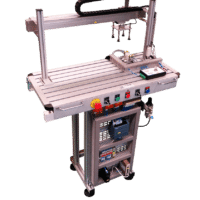

SMC’s FAS-200 is a flexible, modular, and compact industrial assembly system entirely comprised of industrial automation technologies from global leaders.

The FAS-200 comprises up to 18 independent stations with integrated control. This modular equipment features a higher number of stations in the same space, which means that more users will be able to work at the same time.

In addition, it enables making a staggered investment, i.e. starting with an initial basic configuration which can be easily enhanced by adding workstations.

FAS-200 offers professional skills training to suit the world of industry using standardized industrial components.

The different process stations assemble a turning mechanism. To provide the system with greater flexibility, the stations adapt to a wide variety of assemblies, introducing variations in the materials, colors and part sizes. The combination of all these options means that a total of 24 different assemblies can be produced enabling the use of production management strategies.

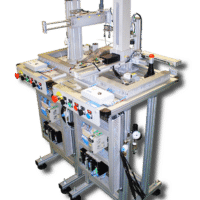

Each of the FAS-200 system stations carries out part of the process.

Common elements in all stations: Power supply, anodized aluminium structure, control keypad, solenoid valve block, labels for cables, electric connection terminals, speed controllers, air treatment unit, control PLC* and manual user manual and practice manual.

A troubleshooting simulation system TROUB-200 is included in each station, which generates up to 16 different breakdowns to be diagnosed by the user in every station of the FAS-200.

FAS-201: Base Feeding + Verification Station

This station feeds the base that serves as support to the assembled product and verifies its correct orientation.

FAS-202: Base Rejection + Transfer Station

This second station positions the correctly placed bases on the pallet and rejects those which are incorrect.

FAS-203: Bearing Feeding + Transfer Station

This station supplies the bearing and moves it to the measuring position. Bearings can be inserted with two different heights.

FAS-204: Bearing Measuring + Transfer Station

This station measures the height of the bearing provided by the previous station and inserts it into the base. The measurement is performed using a series of actuators and a probe that acts on a linear potentiometer. In the event that the bearing height is not suitable, it will be rejected.

FAS-205: Hydraulic Pressing Station

In this phase of the process, the bearing is pressed down via hydraulic actuator.

FAS-206: Transfer Station to the Hydraulic Press

This station feeds the work-piece to the FAS-205, the hydraulic pressing station. After pressing, it picks it up / drops it on the pallet.

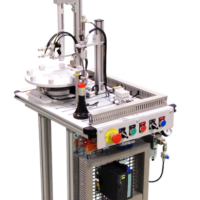

FAS-207: Shaft Classification Station

This station feeds the assembly shafts and verifies their material and position. Two types of shafts exist depending on the material: aluminium and nylon. This increases the number of possible finished products which are assembled, while also increasing the didactic capacities of the FAS-200.

The different operations undertaken in this station are distributed around an index plate. The operations are: shaft feeding, measuring shaft height and material detection.

FAS-208: Shaft Rejection + Transfer Station

This station rejects the shafts which are incorrectly aligned or are the wrong material and inserts the correct ones into the work-piece.

FAS-209: Lid Classification Station

This station feeds and inspects the lids to be assembled in the work-piece. There are 6 different types of lids depending on the material (aluminium or nylon), color (light or dark) and height (high or low).This variety offers the station more didactic possibilities. The operations carried out in this station are distributed around an index plate.

FAS-210: Lid Rejection + Transfer Station

The tenth station rejects the lids or inserts them in the work-piece if the lid provided by the previous station is of the required type.

FAS-211: Screw Dispensing Station

This station feeds and transfers the screws to be assembled in the work-piece to the following station.

FAS-212: Screw Insertion Station

This station inserts the screws into the base of the work-piece. Given that screw feeding is carried out at only one point, an additional mechanism has been included in the transfer to carry out the successive rotations of the pallet.

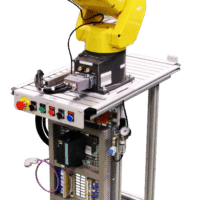

FAS-213: Robotized Screwing Station

This station integrates robotics technology which is widely used in automated environments.

In this part of the process, an industrial robot fastens the four screws inserted into the product by the previous station. You may choose any brand/model robot that fits on the training system, including Fanuc, ABB, Universal Robots, Motoman, and more.

FAS-214: Transfer and Visual Inspection Station

This station performs the quality control of the work-piece using an artificial vision system. From the inspection position, an artificial viewing system examines the assembled components.

FAS-215: Rejection Station after Visual Inspection

This station rejects the work-piece if the inspection result is unsatisfactory.

FAS-216: Storage Station

This station stores the finished product.

The warehouse has been set up using a system based on three coordinate shafts, one of them servo-controlled.

FAS-220: Pallet Transfer Station

This station transfers the pallet with the work-piece from one transfer to another in a parallel configuration.

*Options: PLC Siemens, Omron, Allen Bradley or without PLC.