Description

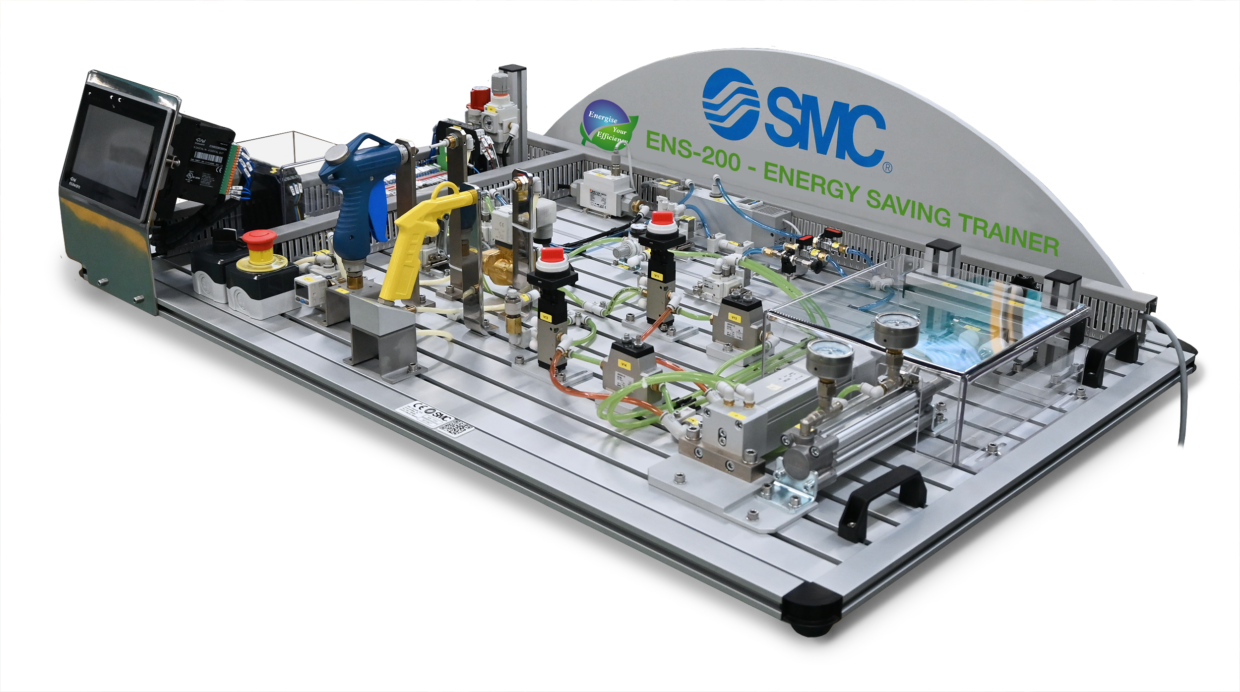

The SMC ENS-200 Automation Energy Savings Trainer teaches students how to reduce cost and increase sustainable manufacturing processes ENS-200 includes an HMI (Human Machine Interface) with a built-in PLC, interactive menus guide students and technicians through the different activities.

The system sets up all of the parameters automatically for each exercise.

The results from measuring consumption and the savings obtained are presented as a percentage and in monetary savings.

Teaching Content

PRESSURE

ENS-200 facilitates comparing the effect of adjusting the operating pressure to meet the facilities requirements using the following types of activities:

• Comparing different types of vacuum ejectors.

• Assessment of the impact of using excessively long pipes.

• Analysis of the impact of using double pressures.

• Adjustment of the network pressure to that required by each actuator.

• Comparison of various types of blow guns.

• Comparison of different various types of blow nozzle.

• Comparison of alternative various types of actuators.

• Analysis of the negative effects of excessive pressure on pneumatic facilities.

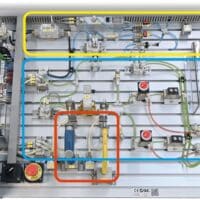

SECTORISATION

ENS-200 looks at the advantages of dividing the facility into different areas, thus favouring the implementation of the following activities:

• Quantifying the advantages of positioning pressure controllers in each area.

• Quantifying the effect of leaks on the consumption and sizing of the compressor.

MONITORING

Monitoring identifies potential savings and verifies their subsequent application. ENS-200 enables:

• Checking whether a machine’s consumption falls within expected limits.

• Detecting and locating leaks in a system by sequentially checking areas or actuators.