Manufacturing

Showing 37–48 of 80 results

-

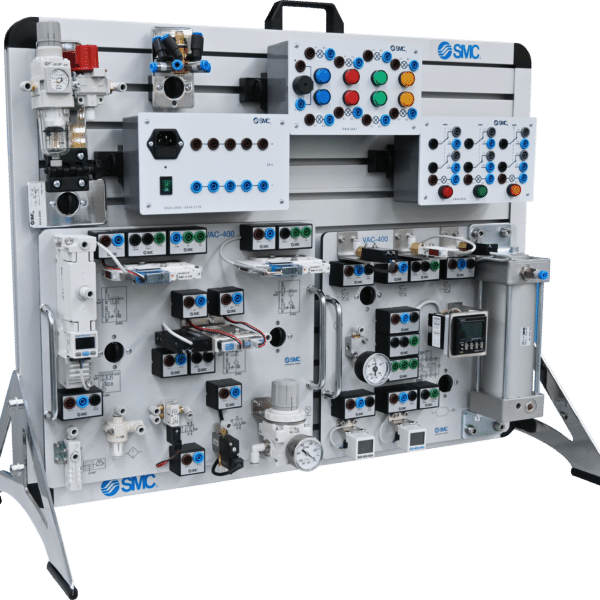

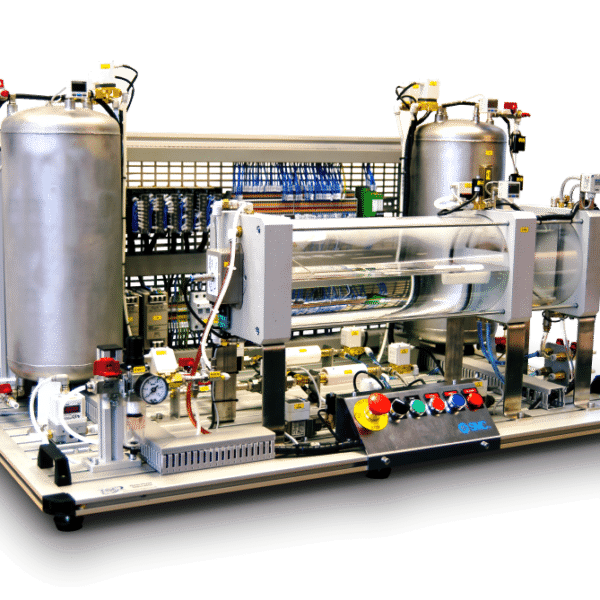

SMC Vacuum Technology Training System

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed a training system specifically for hands-on skills development in Vacuum Technology. Featuring the most commonly found vacuum technologies found in industrial companies like Intel, Dell, Apple, Samsung, Toyota, and more, the VAC-400 is the training system needed for skills development training in vacuum technologies.

-

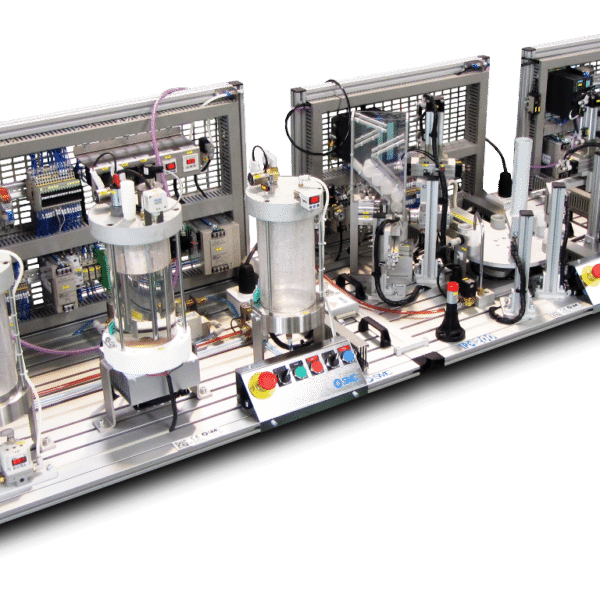

SMC Automated Process Control Training System

The IPC-200 is SMC’s unique training solution specific to automation and process control. Commonly used for training in the food & beverage production and processing industries as well as pharmaceutical industry, the IPC-200 brings real-world industrial skills and technologies to students’ fingertips with an exciting and project-based tabletop training system.

A fully modular and flexible automate process control system, the IPC-200 is comprised of three modules which can work individually or as a complete process line. Various configurations can be created to adapt the IPC-200 equipment to our users different requirements and budgets.

IPC-200 emulates a liquid production and bottling plant and includes the technologies used in a continuous process industry, such as pneumatics, electric motors, sensors, continuous processes, programmable controllers, industrial communications, etc.

It is built entirely from industrial materials so that student works with the same elements found in the working environment.

-

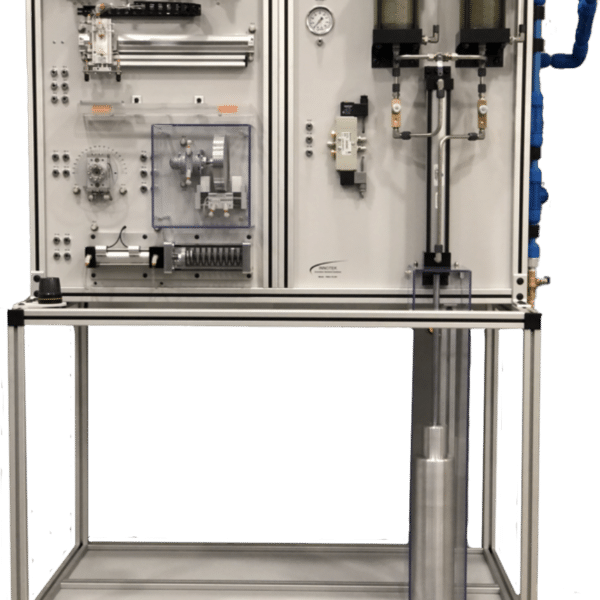

Pneumatic Troubleshooting Training System

Take your Pneumatics training to the next level with our new, hands-on Pneumatic Troubleshooting Training System.

The PNEU-TS-201 Training system provides participants with hardware allowing for hands-on activities in troubleshooting of industrial pneumatic applications. This system gives access to various electrical and pneumatic components which are connected to create six unique applications. The operator control section allows for direct manual and automatic control of each application. Lastly the system includes fault insertion capability to assist in development of a systematic approach to troubleshooting.

The Pneumatic Troubleshooting Training System is the most capable and comprehensive pneumatics training aid of its kind. Complete with Pick & Place, Loading Actuator, Rotary Manipulator, Free Wheeling Motor/Brake, Air Over Oil, and Operator Control Station.

-

SMC Basic Electro-Pneumatics Training System PNEU-403

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed the most state-of-the-art and robust training system for teaching Pneumatics and Electro-Pneumatics Fundamentals to schools, training centers, and colleges. All components are industrial, used by companies around the world, so you can rest assured that your pneumatics learning directly translates to on-the-job relevance.

SMC’s PNEU-403: Basic Electro-Pneumatics Training System is the complete training system for industry-required skills development and in the area of Basic Electropneumatics and includes all air preparation components, mechanical valves, air-operated valves, flow control equipment, actuators, and accessories for hands-on pneumatics training.

The Pneutrainer-400 comes with modular design that allows several customizable options to suite your training needs. Choose you form factor (mobile cart or tabletop), single or double-sided, and choose your training package!

SMC Pneumatics training systems are complete with interactive lesson plans, curriculum, user activities, eLearning and simulation software for the world’s most complete and comprehensive Pneumatics training platforms.

-

SMC Pneumatics and Electropneumatics Training System (PNEU-405)

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed the most state-of-the-art and robust training system for teaching Pneumatics and Electro-Pneumatics Fundamentals to schools, training centers, and colleges. All components are industrial, used by companies around the world, so you can rest assured that your pneumatics learning directly translates to on-the-job relevance.

SMC’s PNEU-405 combines the Basic Pneumatics and Basic Electro-Pneumatics training packages into one comprehensive, hands-on training solution for the study of fluid power. The complete training system for industry-required skills development and in the area of Basic Pneumatics and Electro-Pneumatics, the PNEU-405 includes all air preparation components, mechanical valves, air-operated valves, flow control equipment, actuators, and accessories for hands-on pneumatics training at the high school, technical college and industry levels.

The Pneutrainer-400 comes with modular design that allows several customizable options to suite your training needs. Choose you form factor (mobile cart or tabletop), single or double-sided, and choose your training package!

SMC Pneumatics training systems are complete with interactive lesson plans, curriculum, user activities, eLearning and simulation software for the world’s most complete and comprehensive Pneumatics training platforms.

-

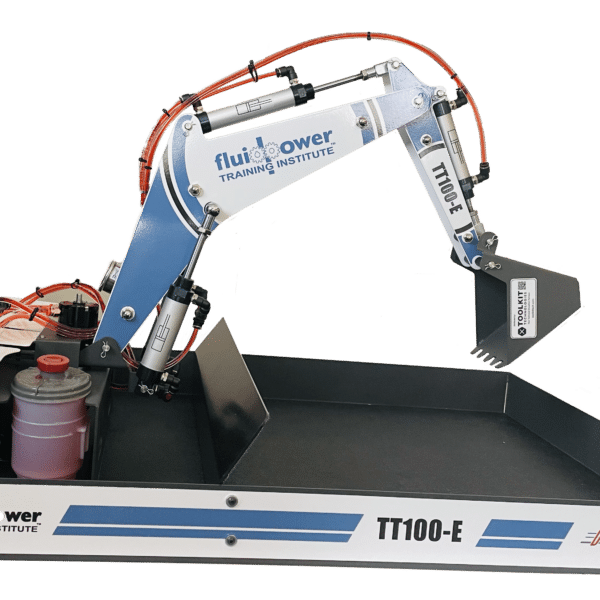

Tabletop Hydraulic Excavator Kit

Our brand new tabletop hydraulics excavator kit brings real-world hydraulic principles to life for students to explore hydraulics in an engaging and project-based approach!

Build your excavator and learn the basic hydraulic concepts necessary for industrial skills in agriculture, industrial maintenance, heavy truck, and manufacturing careers.

Build, Create, Dig, and Learn!

-

SMC Three-Phase Separator

The new 3-Phase Separator Training System from SMC emulates the industrial separation process of the oil, gas and water obtained from oil wells during the oil production process. The process is performed with all gaseous and liquid components in a pressurized container.

A Three Phase Separator for oil production is a large container designed to separate the fluids obtained from the well into its individual constituent components: oil, gas and water. These types of separators are based on the principle that the three components have different densities. This allows separating them when they move slowly, the gas in the upper part, the water in the bottom and the oil in the middle.

SMC’s new 3-Phase Separator Training System includes all hardware, software, and learning content for effective training in process control and three-phase separation concepts.

-

Hirebotics Robotic Welding System

We are proud to represent the #1 robotic welder on the market today in terms of ease-of-use and approachability. Learn why companies across the country are adopting this collaborative robot welding cart in record numbers.

The challenge with implementing robotic welding systems is that rarely can you find expertise in both welding AND robotics. This industrial cobot welding system from Toolkit Technologies and Hirebotics alleviates all hurdles with it’s turn-key, all-in-one system that delivers high quality precision and accuracy, easy-to-use and approachable user interface, and best-in-class results.

Start training the future generation of welders on automation robot welding training carts.

Available with UR10e or UR20 robots.

Available as a Cobot Welder or as a Cobot Plasma Cutter.

-

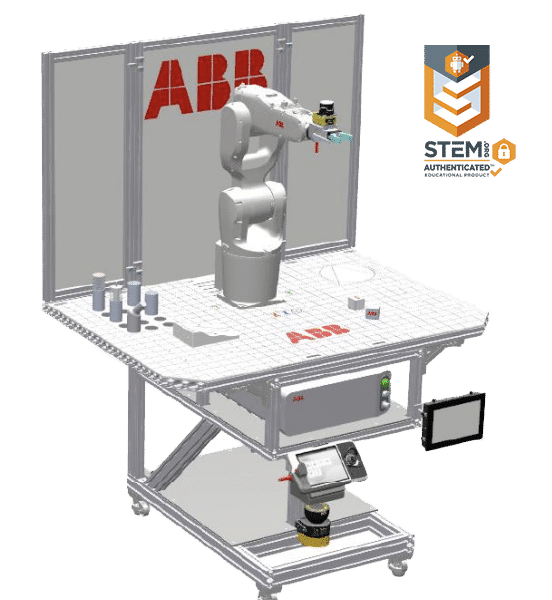

ABB Cobot FlexTrainer STEM Education Cell

Go Faster! Go Farther! Go Further! Go Train on ABB’s new Collaborative Robot, GoFa CRB 15000!

We are thrilled to bring ABB’s newest collaborative robot training system – the ABB Cobot FlexTrainer with ABB’s newest collaborative robot, the GoFa, to education.

The mobile training platform features a sleek design and various industry training applications. Paired beautifully via ABB RobotStudio, students can get hands-on training and virtual/digital solutions with AR/VR.

Now certified and authenticated by STEM.org!

-

Omron Mobile Robot

The Omron LD Mobile Robot is a self-navigating Autonomous Mobile Robot (AMR) designed for dynamically moving material in challenging environments that may include confined passageways as well as dynamic and peopled locations. Unlike traditional autonomously guided vehicles (AGVs), Omron Mobile Robot requires no facility modifications, such as floor magnets or navigational beacons, saving users deployment costs.

-

ABB Fenceless FlexTrainer Robot Training System

The new ABB Fenceless FlexTrainer Cart was designed specifically for education. To bring students face-to-face with one of industry’s leading robots.The hands-on training cart utilizes ABB’s IRB 1200 or IRB 1100 industrial robots for practical, industry-driven skills training. The fenceless collaborative design allows open site-lines to the robot, maintaining safety with an ABB safety sensor located at the bottom of the cell.Now Certified and Authenticated by STEM.orgOther features of the FlexTrainer include:– ABB STEM Education Activity Tabletop (removable)

– Electric Gripper EoAT

– ABB 3D Printed STEM Education Activity Kit for hands-on training activities

– SMC Linear conveyor system

– HMI

– Integrated vision

– SMART Certification and Curriculum for STEM and Robotics

– Large casters for easy transportation

– Fits through a standard door

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.