Manufacturing

Showing 13–24 of 41 results

-

Motor Troubleshooting Training System

The MTS-101 Motor Troubleshooting System provides hands-on hardware for the development of skills and assessment of motor troubleshooting principals. Learners will utilize test equipment including an ohmmeter and megohmmeter to determine the condition of a 3-phase AC motor.

Insertable Faults are included on the side of the training system to allow for practical troubleshooting and testing to take place.

-

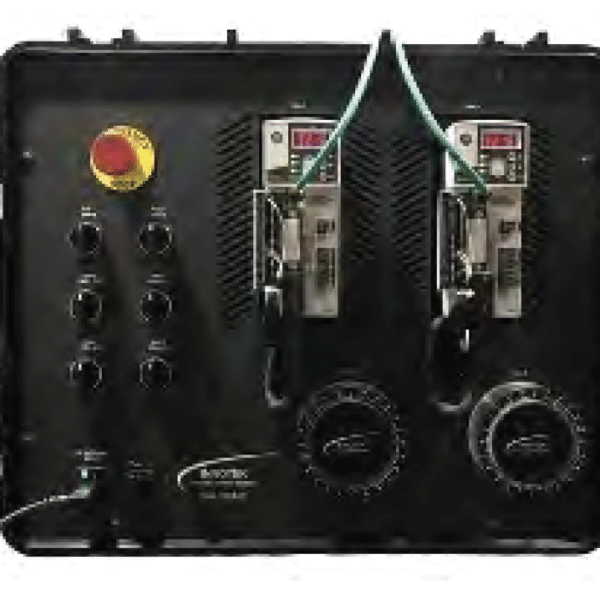

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

Conveyor and Logistics Automation Training System

The Conveyor and Logistics Automation Training System with Troubleshooting is our industrial training solution for school and companies looking for practical and realistic hands-on training activities in areas such as Maintenance, Troubleshooting, and Programming of industrial automation technologies commonly seen in warehouses, logistics settings, and industrial automation factories.

The mobile and modular system includes choices of PLC controller, Variable Frequency Drive, HMI’s, and conveyors. Conveyors stations can include: flatbed slider belt conveyors, roller bed belt conveyors, powered roller conveyor, plastic mesh conveyor, and more.

Up to 32 Troubleshooting Faults can be incorporated so students can troubleshoot and repair faulted components.

-

5-Station Smart Innovative Factory

The 5-Station Configuration of the SMC SIF-400 takes a condensed yet robust look at hands-down the most remarkable, fully-connected Industry 4.0 Training Platform on the market for hands-on training, exploration, and research in advanced manufacturing industries: SMC’s SIF-400.

SMC’s Industry 4.0 Smart Innovative Factory reproduces an industrial, cyber-physical smart factory – in both the production and supply chain – with a modular design of 14 interconnected stations for training and studies in connected systems, operational data and data analytics, IIoT, predictive and preventative maintenance, management execution software (MES), inventory tracking and control, cybersecurity, and more!

-

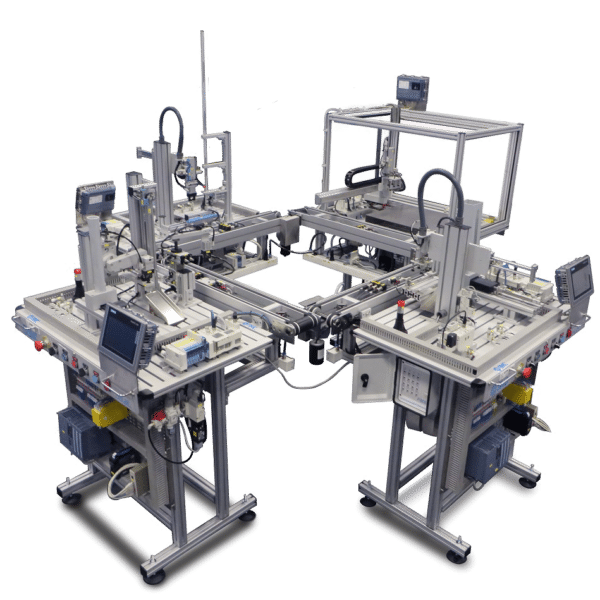

4-Station Flexible Manufacturing System i4o

The best just got better with this incredible training from SMC! The FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training for industry.

The 4-Station Configuration brings classrooms a compact and expandable solution for hands-on Industry 4.0 training with built-in troubleshooting.

Students will get industry-relevant hands-on training around the crucial skills demanded by manufacturing and industry. Industrial manufacturing skills student expect to receive include automation processes, safety, PLC programming, Distributed IO, smart devices, artificial vision, and more!

-

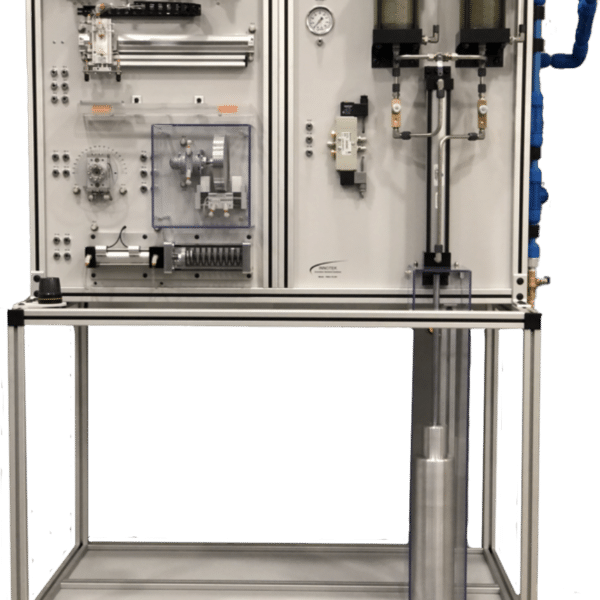

Pneumatic Troubleshooting Training System

Take your Pneumatics training to the next level with our new, hands-on Pneumatic Troubleshooting Training System.

The PNEU-TS-201 Training system provides participants with hardware allowing for hands-on activities in troubleshooting of industrial pneumatic applications. This system gives access to various electrical and pneumatic components which are connected to create six unique applications. The operator control section allows for direct manual and automatic control of each application. Lastly the system includes fault insertion capability to assist in development of a systematic approach to troubleshooting.

The Pneumatic Troubleshooting Training System is the most capable and comprehensive pneumatics training aid of its kind. Complete with Pick & Place, Loading Actuator, Rotary Manipulator, Free Wheeling Motor/Brake, Air Over Oil, and Operator Control Station.

-

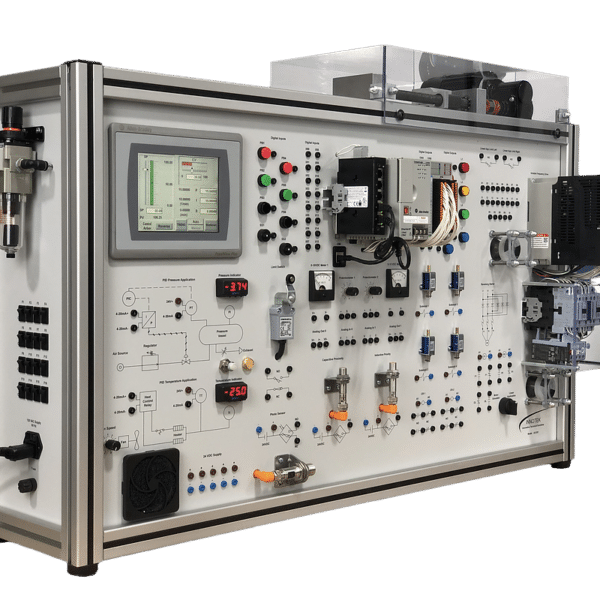

PLC Automation Training System | all-in-one

The ATS-200 Automation Training System provides students with a hardware platform for performing hands-on skills development activities for automation technologies operations. The tabletop or mobile platform includes various applications which can be quickly connected to provide advanced activities, expanding the learning objectives beyond simple on/off functionality.

The all-in-one PLC Training System includes:

◉ Operator Control Application

◉ Sensors and Switches Application

◉ Pneumatic Actuator/Valve Application

◉ Linear Ball Screw Application

◉ BCD Thumbwheel and 7 Segment Display

◉ Dual Analog Potentiometer and Meters

◉ Motor Control Application

◉ Variable Speed Drive (Any Brand)

◉ PLC (Any Brand)

◉ HMI (Any Brand)

◉ PID Pressure Application

◉ PID Temperature Application

The system shown as tabletop trainer with banana jack connections. The unit can be purchased with a mobile frame with all components pre-wired to the PLC requiring no additional connections.

-

Hirebotics Robotic Welding System

We are proud to represent the #1 robotic welder on the market today in terms of ease-of-use and approachability. Learn why companies across the country are adopting this collaborative robot welding cart in record numbers.

The challenge with implementing robotic welding systems is that rarely can you find expertise in both welding AND robotics. This industrial cobot welding system from Toolkit Technologies and Hirebotics alleviates all hurdles with it’s turn-key, all-in-one system that delivers high quality precision and accuracy, easy-to-use and approachable user interface, and best-in-class results.

Start training the future generation of welders on automation robot welding training carts.

Available with UR10e or UR20 robots.

Available as a Cobot Welder or as a Cobot Plasma Cutter.

-

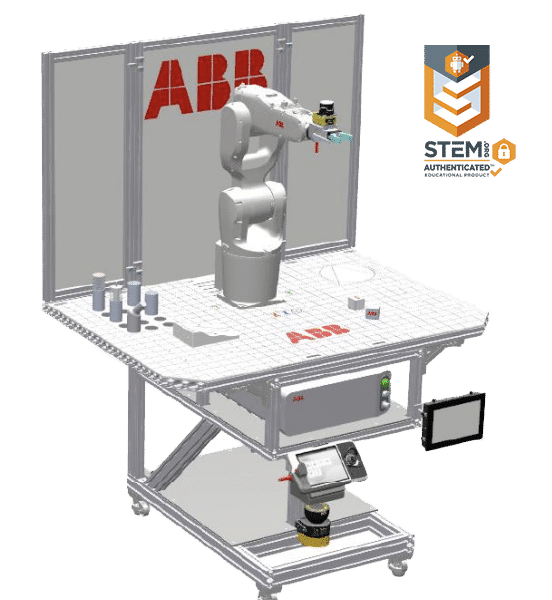

ABB Cobot FlexTrainer STEM Education Cell

Go Faster! Go Farther! Go Further! Go Train on ABB’s new Collaborative Robot, GoFa CRB 15000!

We are thrilled to bring ABB’s newest collaborative robot training system – the ABB Cobot FlexTrainer with ABB’s newest collaborative robot, the GoFa, to education.

The mobile training platform features a sleek design and various industry training applications. Paired beautifully via ABB RobotStudio, students can get hands-on training and virtual/digital solutions with AR/VR.

Now certified and authenticated by STEM.org!

-

ABB Fenceless FlexTrainer Robot Training System

The new ABB Fenceless FlexTrainer Cart was designed specifically for education. To bring students face-to-face with one of industry’s leading robots.The hands-on training cart utilizes ABB’s IRB 1200 or IRB 1100 industrial robots for practical, industry-driven skills training. The fenceless collaborative design allows open site-lines to the robot, maintaining safety with an ABB safety sensor located at the bottom of the cell.Now Certified and Authenticated by STEM.orgOther features of the FlexTrainer include:– ABB STEM Education Activity Tabletop (removable)

– Electric Gripper EoAT

– ABB 3D Printed STEM Education Activity Kit for hands-on training activities

– SMC Linear conveyor system

– HMI

– Integrated vision

– SMART Certification and Curriculum for STEM and Robotics

– Large casters for easy transportation

– Fits through a standard door

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.

-

Tabletop Wiring Training System

The compact, tabletop EW-101 Electrical Wiring Training System allows for hands-on student lab activities in wiring residential, commercial/industrial, HVAC, and low-voltage systems (fire alarm, security system, etc) circuits.

The double-sided, hands-on training system gives students safe and approachable access to wire various circuits and devices commonly found in real world settings.

Customize your system by choosing your training focus (two per training system):