Manufacturing

The need for skilled, qualified, and capable manufacturing workers across the globe, especially here in the US, is one that will continue to rise for the foreseeable future.

Toolkit Technologies is focused on bringing the needed technologies, curriculum, and digital solutions to schools across the country that will train the next generation of manufacturing professionals and leaders.

Our manufacturing training solutions range from integrated mechatronics systems to electrical, sensors, mechanical, fluid power, robotics and more.

Our goal is clear and consistent: to train the future leaders of industry on the leading technologies from industry.

Showing 1–12 of 14 results

-

SMC Smart Innovative Factory Training System

Take a look at the most remarkable, fully-connected Industry 4.0 Training Platform on the market for hands-on training, exploration, and research in advanced manufacturing industries: SMC’s SIF-400.

SMC’s Industry 4.0 Smart Innovative Factory reproduces an industrial, cyber-physical smart factory – in both production applications and supply chain applications – for a school to provide real-world advanced manufacturing training. The training system is a modular design comprised of 14 interconnected stations for hands-on training and research of connected systems, operational data and data analytics, IIoT, predictive and preventative maintenance, management execution software (MES), inventory tracking and control, cybersecurity, and more.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

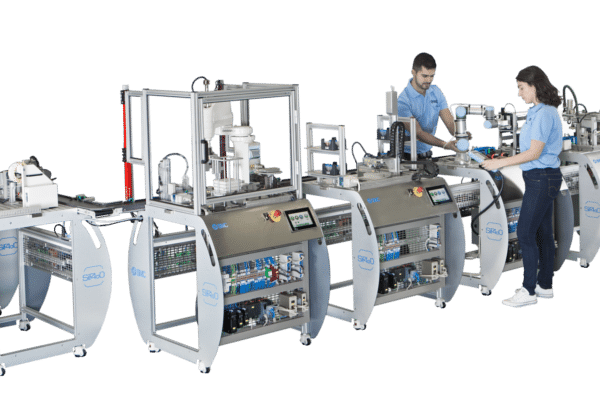

SMC Mechatronics + Industry 4.0 Learning System (M&I-400)

The newest training system for developing skills in both Mechatronics and Industry 4.0 technologies.

SMC’s M&I-400 is a learning system designed for training on industrial technologies in mechatronics and industry 4.0, while being incredibly attractive and visually appealing. The industrial system makes it easy for students to attain industry’s most needed skills through exciting and practical activities, while also attracting students to learn these skills and technologies.

Projects and activities can be carried out that motivate students to explore Industry 4.0 concepts and technologies while also learning important fundamental concepts related to Mechatronics.

SMC’s M&I-400 emulates a highly automated factory, where different types of products are produced, packed and shipped. The M&I-400 training system makes it possible to work on advanced and connected manufacturing concepts.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

SMC Flexible Manufacturing System – Industry 4.0

The best just got better with this incredible training from SMC! SMC’s FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market for mechatronics and industrial troubleshooting training and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training.

The SMC Flexible Manufacturing System is used by countless companies and schools across the globe for real industry training.

-

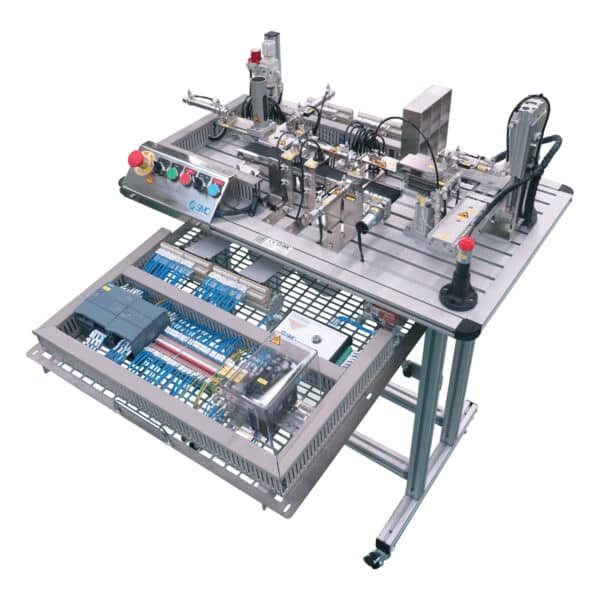

SMC Compact Automation Training System (Automate-200)

SMC’s exciting compact training system for Automation and Mechatronics, AUTOMATE-200, is the perfect training aid for students in advanced manufacturing classrooms for hands-on skills in PLC Programming, Sensors, Pneumatics, Troubleshooting, and More! Developed in partnership with Intel for training in the semiconductor industry, featuring all industrial SMC Components.

-

Highly Automated Training System HAS-200

Train your students with the same Industry 4.0 training system used by companies like Intel and Boeing for their workforce training!

The HAS-200 SE i4o brings SMC’s industry leading technologies into a modular, customizable smart factory for education with training options in PLC programming, HMI programming, Management Execution Systems software, interconnected systems, smart devices, robotics, and more.

-

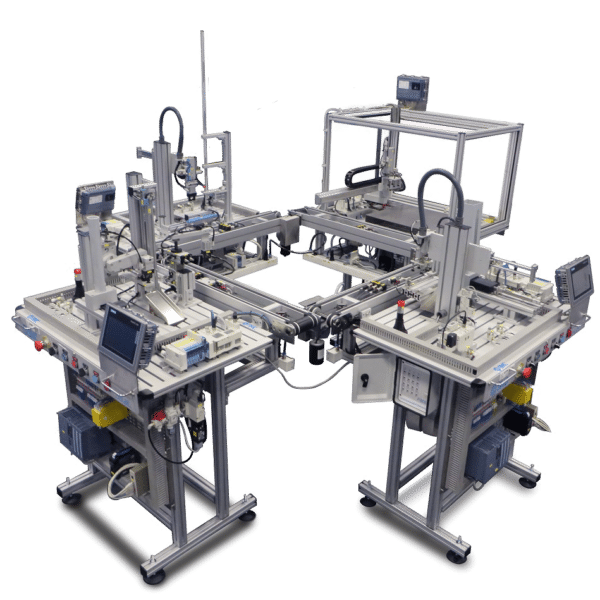

4-Station Flexible Manufacturing System i4o

The best just got better with this incredible training from SMC! The FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training for industry.

The 4-Station Configuration brings classrooms a compact and expandable solution for hands-on Industry 4.0 training with built-in troubleshooting.

Students will get industry-relevant hands-on training around the crucial skills demanded by manufacturing and industry. Industrial manufacturing skills student expect to receive include automation processes, safety, PLC programming, Distributed IO, smart devices, artificial vision, and more!

-

OnRobot RG2 Robot Gripper

ASK FOR EDU DISCOUNTS!

The OnRobot RG2 – 2kg payload robot arm gripper is a flexible, collaborative gripper with built-in Quick Changer and is the perfect 2-Finger Adaptive Robot Gripper for your robot needs.

With OnRobot, swapping in- and- out grippers is as easy as the push of a button! Quick-Change Grippers for all of your robot gripper needs!

-

OnRobot RG6 Robot Gripper

ASK FOR EDU DISCOUNTS!

The OnRobot RG6 – 6kg payload robot arm gripper is a flexible, collaborative gripper with built-in Quick Changer and is the perfect 2-Finger Adaptive Robot Gripper for your robot needs.

With OnRobot, swapping in- and- out grippers is as easy as the push of a button! Quick-Change Grippers for all of your robot gripper needs!

-

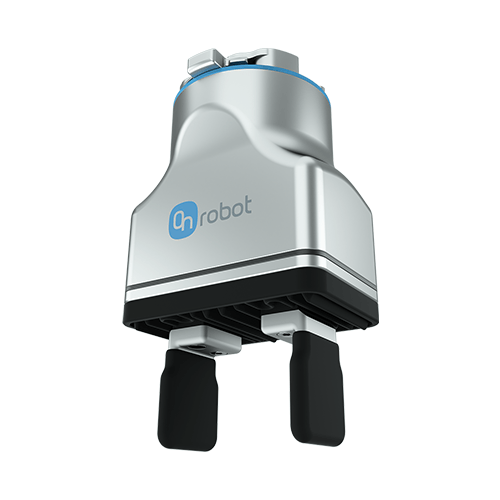

OnRobot 2FG7 Parallel Gripper

ASK FOR EDU DISCOUNTS!

OnRobot’s 2FG7 is the tried-and-true, complete, low-cost, off-the-shelf electric parallel gripper that can be deployed within minutes and requires no custom engineering for installation, programming, or maintenance. The 2FG7 is easily redeployed on any major collaborative or light industrial robot, making it ideal for low-volume, high-mix production, and enabling fast ROI for many different applications.

Like all OnRobot grippers, the 3FG15 offers seamless integration with the robots of your choice, and is quickly swappable with the press of a button.

-

OnRobot 3FG15 3-Finger Gripper

ASK FOR EDU DISCOUNTS!

OnRobot’s 3FG15 3-Finger Gripper is ideal for gripping a wide range of cylindrical objects in machine-tending applications such as CNC lathe machines. The gripper’s design automatically centers workpieces, resulting in fast deployment with a strong, stable grip and precise placement. With a payload of up to 15kg, the 3FG15 competes with larger, bulkier, and much less flexible finger grippers.

Like all OnRobot grippers, the 3FG15 offers seamless integration with the robots of your choice, and is quickly swappable with the press of a button.

-

OnRobot VGC10 Electric Vacuum Gripper

ASK FOR EDU DISCOUNTS!

The OnRobot VGC10 is the COMPACT, versatile electric vacuum gripper for all different types of robotic pick & place applications! Adjust the fingers, footprint, and suction independently.

With OnRobot, swapping in- and- out grippers is as easy as the push of a button! Quick-Change Grippers for all of your robot gripper needs!

-

OnRobot VG10 Electric Vacuum Gripper

ASK FOR EDU DISCOUNTS!

The OnRobot VG10 is the versatile electric vacuum gripper for all different types of robotic pick & place applications! Adjust the fingers, footprint, and suction independently.

With OnRobot, swapping in- and- out grippers is as easy as the push of a button! Quick-Change Grippers for all of your robot gripper needs!