Description

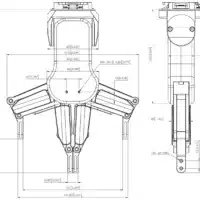

OnRobot’s RG6 – 6kg payload, 2-Finger Gripper is a flexible and adaptive collaborative gripper with built-in Quick Changer and up to 150mm stroke.

It provides intelligence, fast deployment, easy customization and programming on your choice of Robot.

The RG6 gripper can be combined with the Dual Quick Changer module. The Dual Quick Changer operates with the same principles as the Quick Changer module. However, the Dual Quick Changer is designed to enable the use of two end-of-arm tooling grippers (EoAT) at the same time, allowing, e.g., a RG2 gripper and a RG6 Gripper to be used simultaneously.

Our unique robot end-of-arm tooling gripper helps you maximize the use of your robots. With the Dual Quick Changer installed, production time is reduced, because more work pieces are being handled simultaneously. Overall, the Dual Quick Changer will approximately increase production efficiency by 50%.

Automatically detects the stroke at program start without initialization. The maximum grip stroke of the RG6 is 150 mm (adjustable).

The fingertips of the gripper can be easily customized, fitting the product shape for stable gripping. Have CAD students design and 3D print their own!

Automatic payload calculations simplify the programming of the RG6 gripper.

Automatic “lost grip detection”, “grip detected”, “continuous grip” and “measure width” detections remove the need for manually programming these features.

AUTOMATIC TOOL CENTER POINT CALCULATION (TCP)

Automatic calculation of TCP eliminates the need for extensive programming in addition to reducing the deployment time.

Automatic depth compensation ensures the gripper’s fingers sweep in parallel across work surfaces.