Mechatronics

Showing 13–24 of 27 results

-

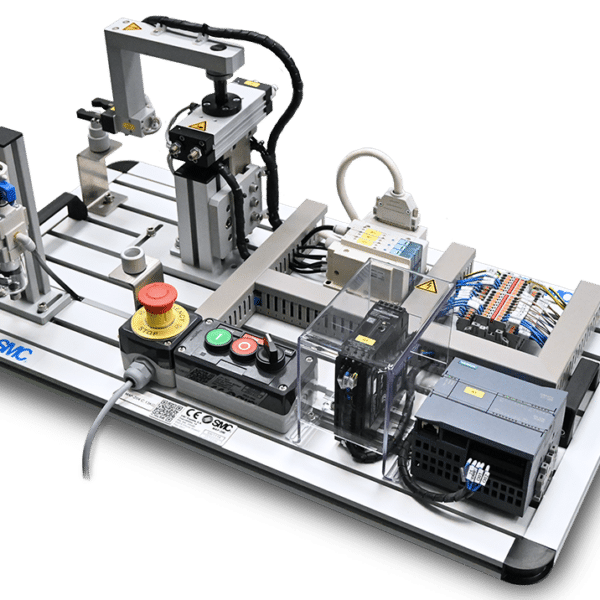

Horizontal Rotolinear Material Handling Training System – MAP-204

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-204: Vertical Revolving Handling Training System with Internal Gripper

The function of the handling device is to transfer the part from a starting area to an unloading area through a rotolinear actuator that displaces an outer gripper. The part being transported is a metal bearing.

The part used is made from anodized aluminum, 14.6mm diameter and 41mm height, so that when the part is placed on the unloading area it fits perfectly onto a stainless steel pivot with a slightly larger diameter than the shaft.

-

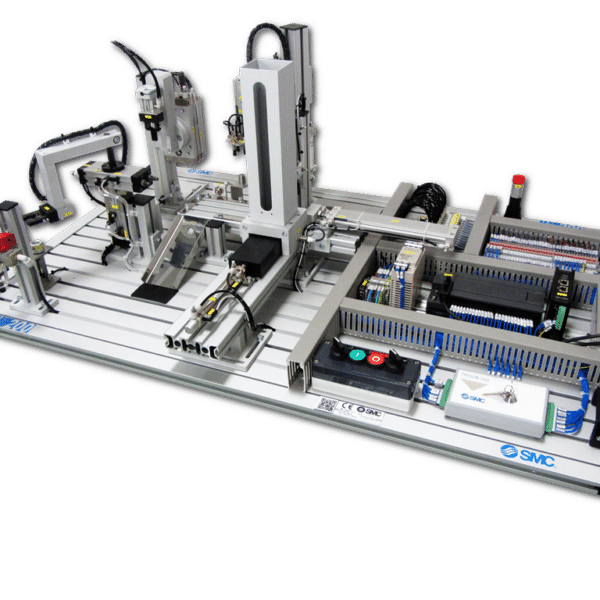

Mini-Cell Material Handling Assembly MAP-205

The MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

The MAP-205 combines the MAP-201, MAP-202, MAP-203, and MAP-204 into a single integrated mini-cell assembly.

The MAP-205 assembles and disassembles a product (metal turning mechanism) via 4 handling devices working together on a single tabletop frame.

- Feeding the base

- Assembling the bearing

- Inserting the shaft

- Placing the lid

-

Modular Assembly System MAS-200

Build upon your mechatronics and automation studies with the MAS-200 Modular Assembly System from industry-leaders at SMC.

This hands-on training system emulates a real industrial assembly process, incorporating the major technologies required by today’s automated industry into one, compact system.

The complete system consists of five stations that work both independently and in unison to assemble a complete product with a metal base, bearing, shaft and lid. The fifth station is located between the others and is responsible for transferring and assembling the parts; which can be done via a pneumatic assembly or robotic assembly.

The modular design of the equipment allows a vast range of options since the stations are completely autonomous, but can be assembled to form a complete manufacturing cell.

MAS-201: Base Feeding Station

MAS-202: Bearing Insertion Station

MAS-203: Shaft Insertion Station

MAS-204: Lid Positioning Station

MAS-205: Transfer and Assembly Station – Robotic or Pneumatic

-

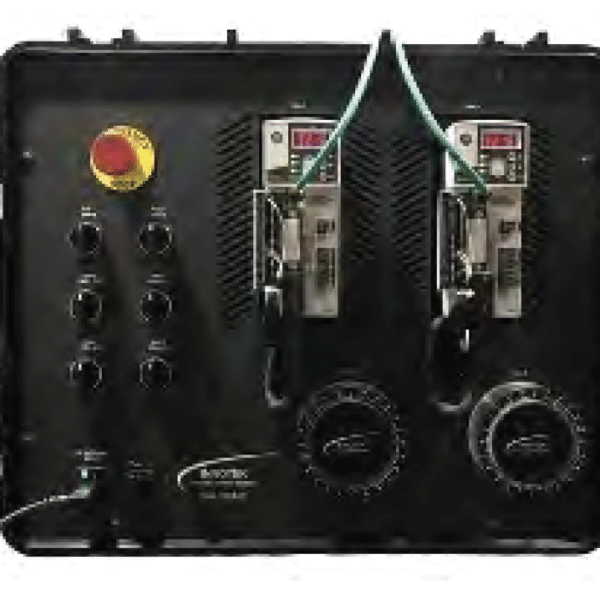

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

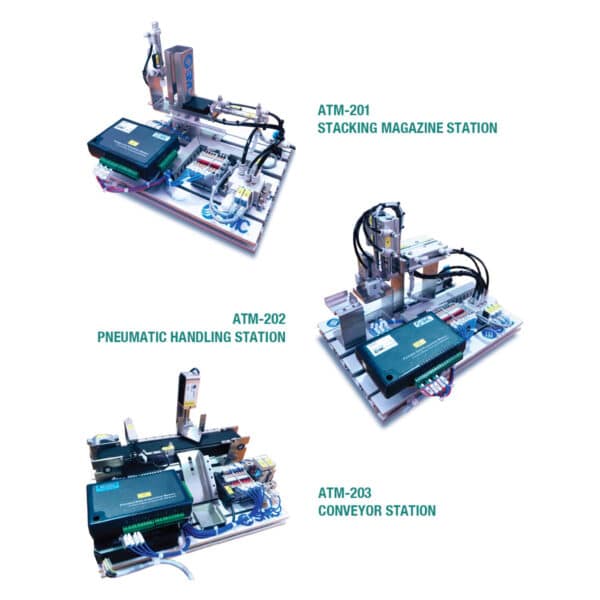

SMC Tabletop Intro to Automation Training Modules (ATM-200)

SMC’s tabletop intro to Automation Training Module, ATM-200, is the perfect training system for high school automation, mechatronics, and exploratory career pathways. Learn and acquire hands-on skills in electricity, pneumatics, programming, sensors, and more!

Each training module consists of (3) tabletop training stations and site license to autoSIM simulation software for virtual training in pneumatics, electrical, hydraulics, and control circuits.

-

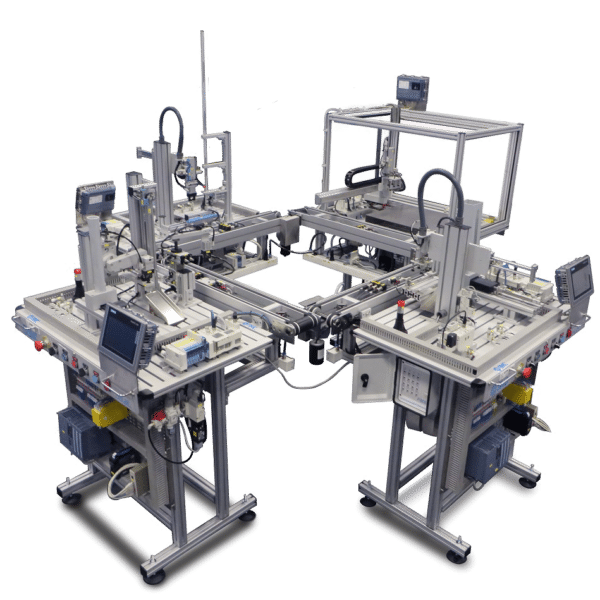

4-Station Flexible Manufacturing System i4o

The best just got better with this incredible training from SMC! The FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training for industry.

The 4-Station Configuration brings classrooms a compact and expandable solution for hands-on Industry 4.0 training with built-in troubleshooting.

Students will get industry-relevant hands-on training around the crucial skills demanded by manufacturing and industry. Industrial manufacturing skills student expect to receive include automation processes, safety, PLC programming, Distributed IO, smart devices, artificial vision, and more!

-

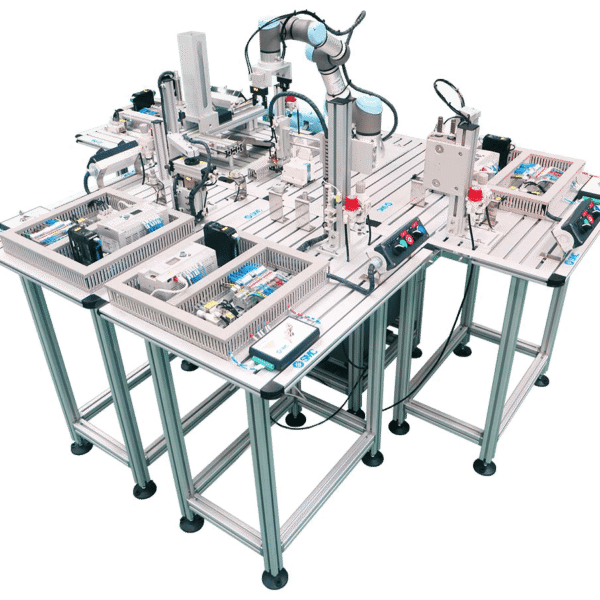

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.

-

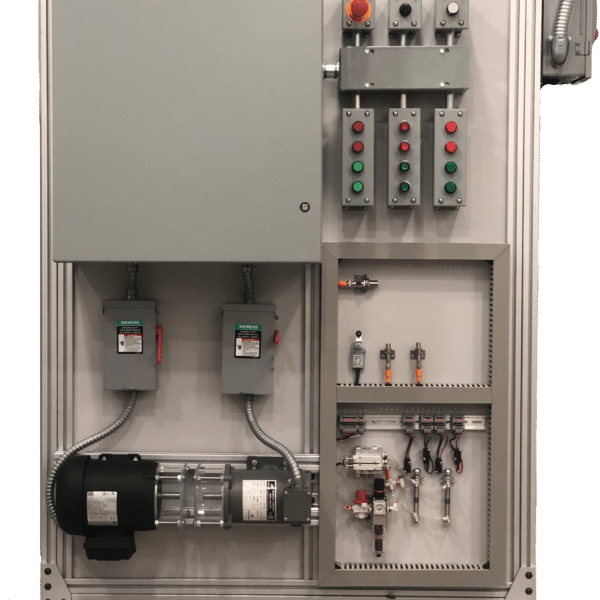

Industrial Wiring Training System

The IW-201 Industrial Wiring Training System is a complete hands-on training solution for teaching the concepts of residential, commercial and industrial wiring in a compact and mobile classroom setting.

The Innotek Industrial Wiring Training System IW-201 allows students to study and practice electrical wiring skills like conduit bending, installing and wiring motor controls in a NEMA Electrical panel, terminating wires and choosing correct wire size, installing wiring into devices, and more!

The skills-based approach of the IW-200 is an invaluable tool for students studying/training to be electricians, industrial maintenance technicians, and/or advanced manufacturing operators, as it builds confidence through hands-on activities and competency-based exercises.

- Power Distribution, Wiring, and Devices

- Conduits and Enclosures

- Industrial Controls

-

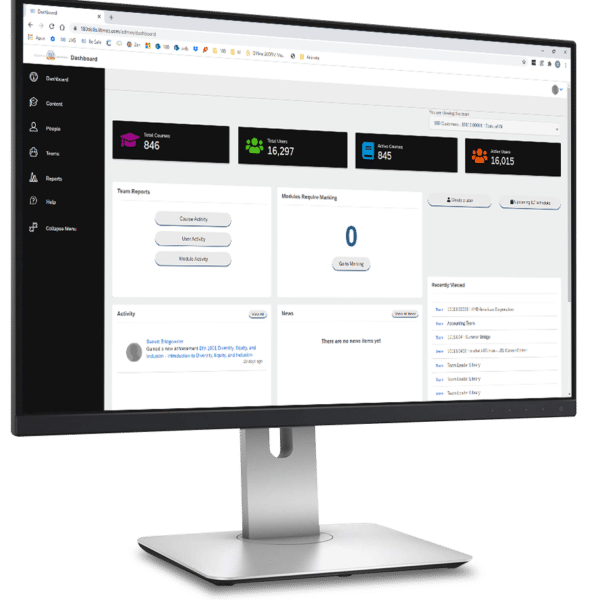

CTE + Workforce eLearning

Toolkit is proud to partner with Valor, 180 Skills, and SMC to bring you the most complete, thorough, and comprehensive eLearning solution for Career and Technical Education. An AWARD-WINNING Learning System for CTE, Workforce Development, and Industry Training.

Web-based eLearning content in over 900 courses – ranging from Career and Technical Education skills, Workforce Development training, Soft Skills development, and more!

Our new eLearning is the most comprehensive skills-based training program out there for real-world skills, certifications, and job-ready outcomes.

Over 600 Technical Skills Courses!

Over 200 Employability and Soft Skills Courses!

Over 80 Quality + Compliance Skills Courses!

-

SMC eLearning

SMC eLEARNING-200 is a flexible, web-based learning platform for skills-based, industry-driven learning to take place anywhere, anytime there is the motivation to learn!

Users can develop skills and theoretical knowledge around Automation and Technical topics such as Robotics, PLCs, Electrical, Pneumatics, Hydraulics, Motors, Sensors and More.

-

Automation Training Simulator – autoSIM

The autoSIM-200 simulation software is our all-encompassing digital software from SMC for creating, simulating, and visualizing Electrical, Pneumatic, Hydraulic and Control Circuits.

With autoSIM-200, it is possible to carry out dynamic, multi-color simulations using pneumatic, electro-pneumatic, hydraulic, electro-hydraulic, electrical and electronic circuits. A Library stocked with Industrial Component are displayed by means of drop-down menus, showing individual standardized symbols, including conventional and proportional pneumatic and hydraulic valves.

autoSIM-200 can be used to create Grafcet diagrams, Ladder, Logigramme (logic gates) and function blocks with structured text. By running the simulation, it is possible to monitor and control the application step by step.

autoSIM 2D provides students with practical lab activities and proposed circuit simulations for SMC Training Systems.

autoSIM 3D delivers students the 3D virtual models of SMC mechatronics training systems for programming, controlling, and monitoring automated processes.

-

SMCTwin-400 Digital Twin Software

We are thrilled to bring the first Digital Twin training software to schools across the globe with SMC’s revolutionary Digital Twin-400 software.

SMCTwin-400 is an online, one-for-one emulation platform where students will be able to develop and control digital twin models. All models operate and behave in the exact manner in which they would in the real world, giving students a never-before-seen lens to view automation and industry.

This true Industry 4.0 software provides students with the ability to access virtual replicas of real SMC training equipment and industrial components, allowing them to safely experience industrial technologies and processes, monitor all of the system’s electrical and pneumatic values, program and create various PLC/HMI programs, and witness the results in real time!