Industrial Training from

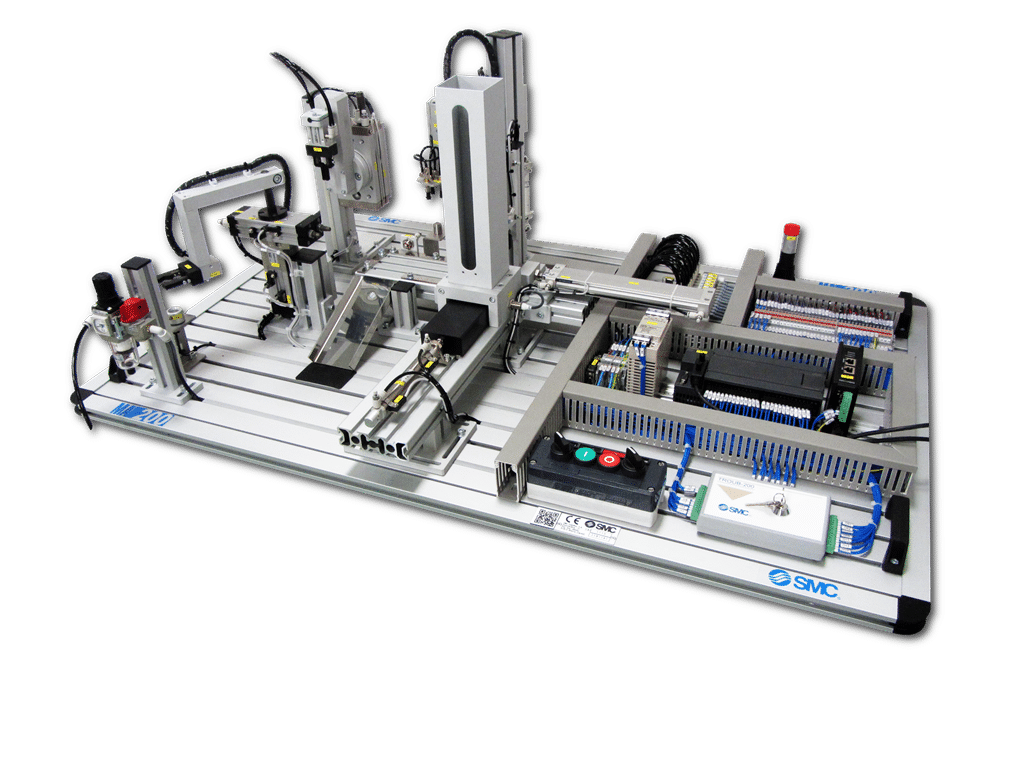

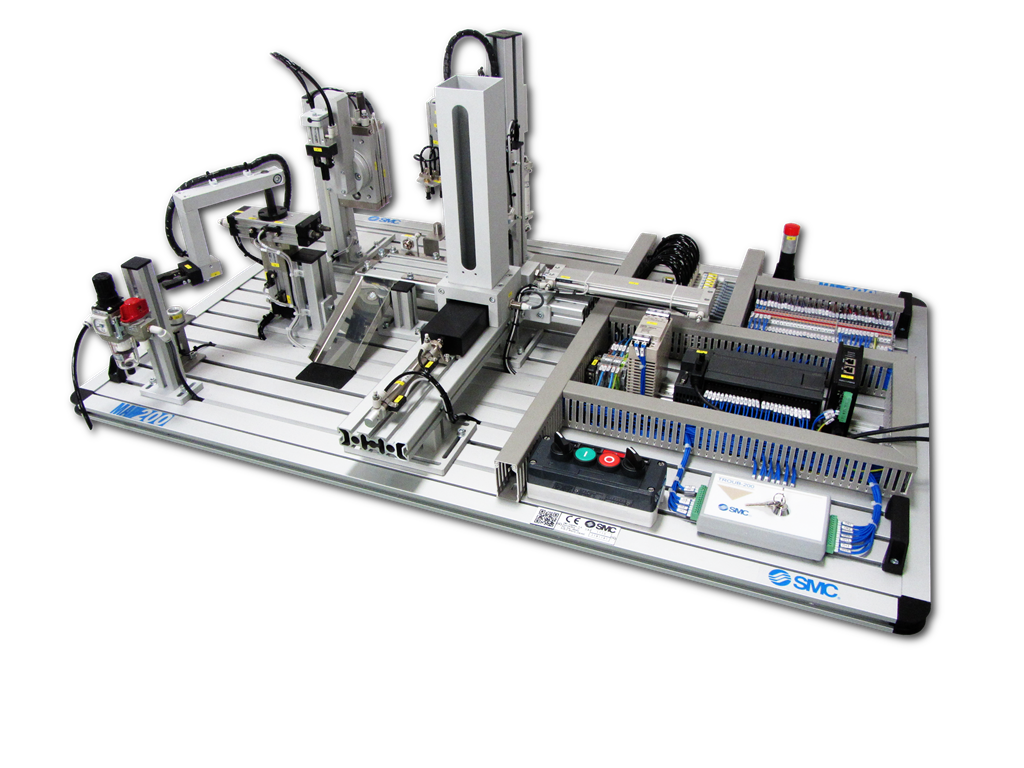

MAP-200 SERIES

TABLETOP MATERIAL ASSEMBLY TRAINERS

PLC PROGRAMMING

& TROUBLESHOOTING

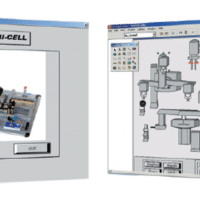

The MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

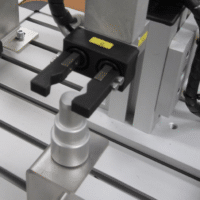

The MAP-205 combines the MAP-201, MAP-202, MAP-203, and MAP-204 into a single integrated mini-cell assembly.

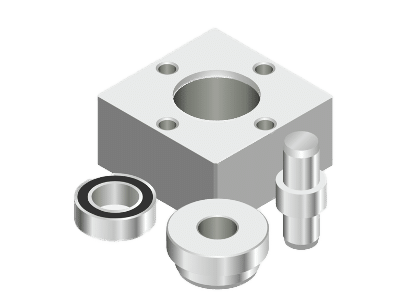

The MAP-205 assembles and disassembles a product (metal turning mechanism) via 4 handling devices working together on a single tabletop frame.

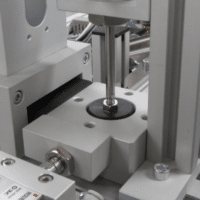

- Feeding the base

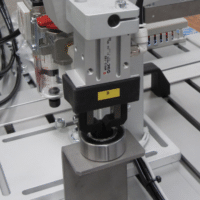

- Assembling the bearing

- Inserting the shaft

- Placing the lid

Pricing upon request

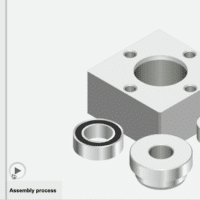

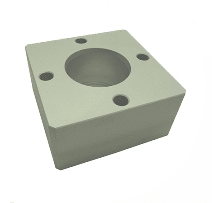

MAP-200 Body Supply Block

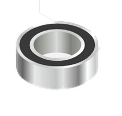

MAP-200 Bearing Insert Part

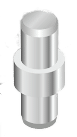

MAP-200 Shaft Insert Part

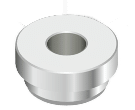

MAP-200 Cap Insert Part

Industrial Skills Made Accessible

Industrial Technology and Automation Training Systems

From the Classroom to the Workforce

Industry's #1 Automation Manufacturer

SMC APPLIES ITS GLOBAL EXPERTISE IN INDUSTRIAL AUTOMATION AND ADVANCED MANUFACTURING TO CLASSROOM LEARNING ENVIRONMENTS WITH A COMPLETE PORTFOLIO OF AUTOMATION TRAINING SYSTEMS.

-

- Hands-on, Real-World Technologies that mirror the same technologies relied upon by leading industrial companies like Intel, Apple, Dell, Rockwell Automation, Boeing, and more.

Industry's #1 Automation Manufacturer

Forbes lists SMC as one of the top 1000 largest companies , as ranked by metrics such as Sales, Profits, Assets , and Market Value.

$36B+ and #1 in marketshare in the US and globally.

World's Best Employers

SMC is one of the best companies to work for according to an anonymous survey measuring employee satisfaction, economic impact , image, trust , gender equality, talent development , corporate social responsibility, culture, and benefits.

Most Innovative Companies

SMC was ranked #49th in a global survey of the most innovative companies, along with peers such as Apple, Google, Rockwell Automation, Siemens , etc.

SMC invests huge in R&D, and continues to forge an innovative and better path forward.

Industry Based Certifications

When schools care what certifications their students attain - that are not mere rubber-stamp certificates - and how marketable their students are for industry jobs, look no further than certifications from and for industry.

CUSTOMIZE YOUR INDUSTRIAL TRAINING PROGRAMS

We're here to help create the training program that fits with you school's and/or company's needs.

Our team of experts can perfectly align industry needs with student outcomes. And our industry-leading technology experts can craft the training system(s) to meet your needs, budget, and space requirements.

Suitcase Technology Trainers

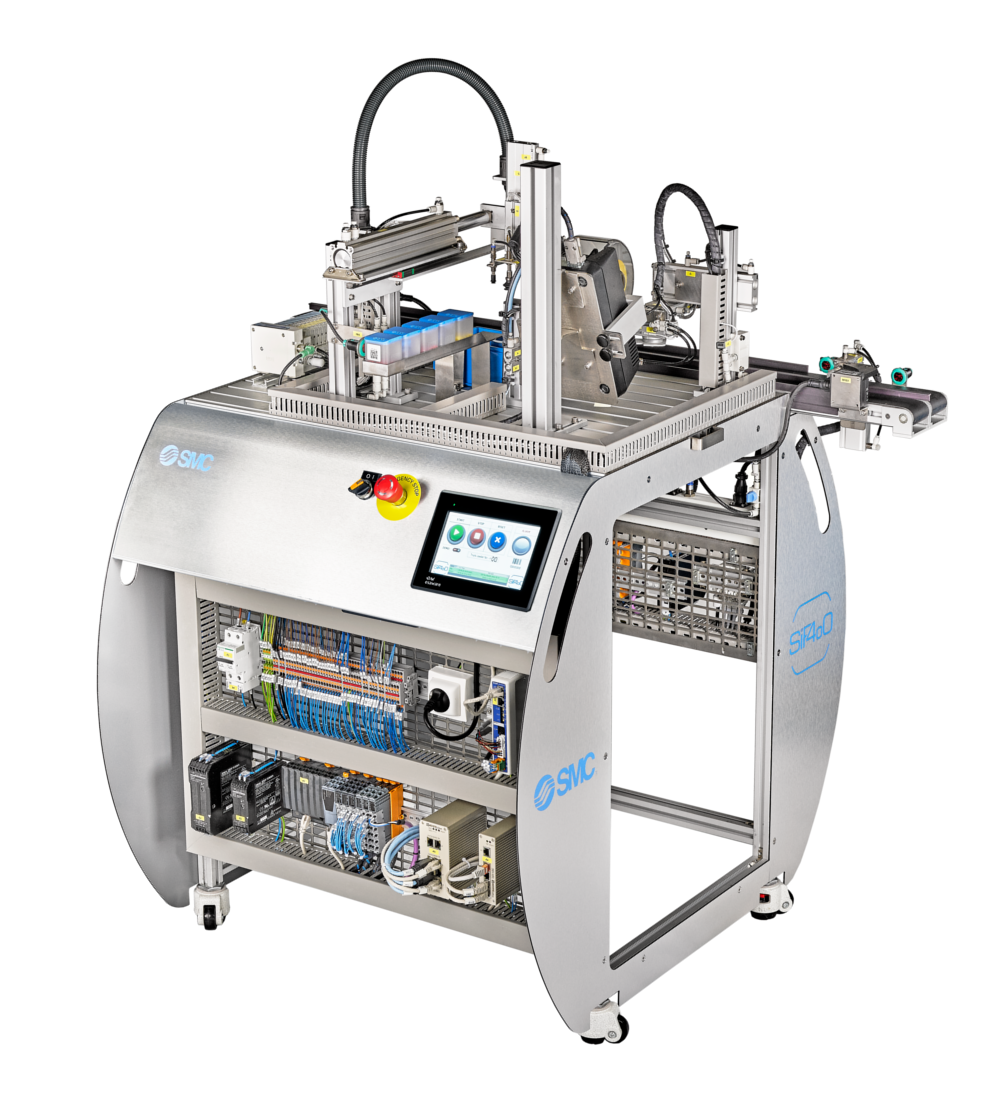

Tabletop Trainers

Tabletop Training Systems

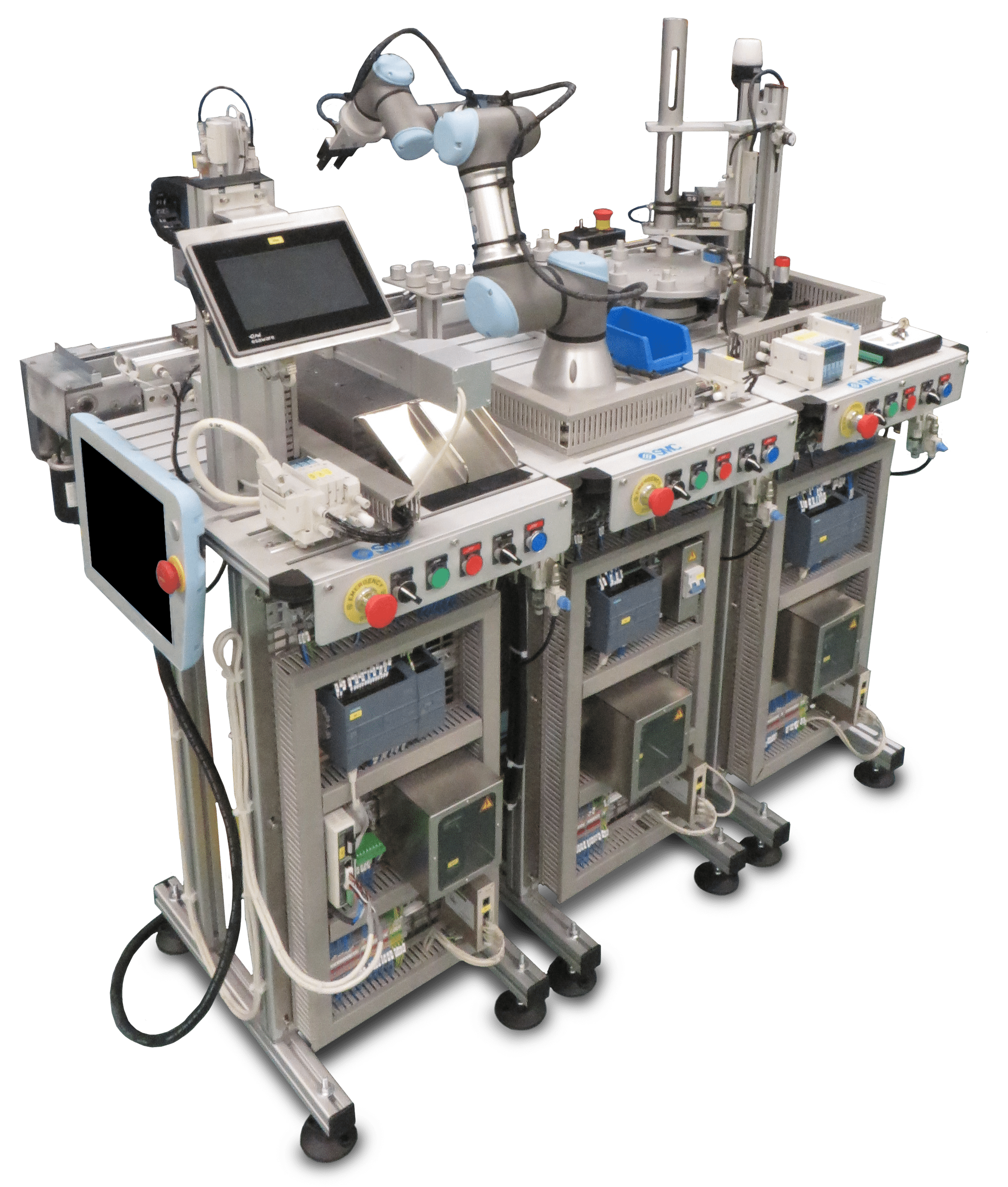

Integrated Systems Trainers

Complete Factory Systems

See how toolkit can help your program

Reach out to our sales team to see which Tenstar configuration would best serve your education or training program!

Sales

sales@toolkittech.com

(512) 203-0590

General

info@toolkittech.com

"*" indicates required fields