Starting a program for

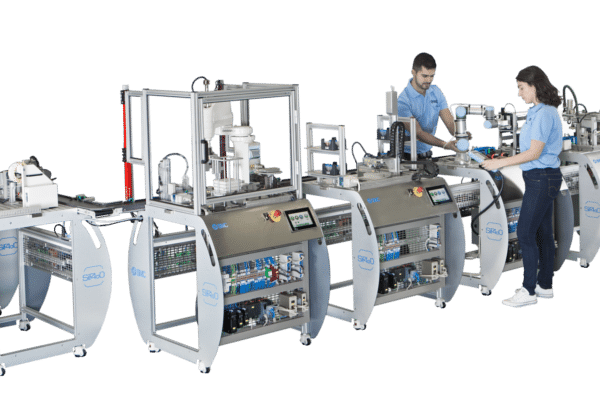

Industrial Maintenance

Ready to use

Course Framework

Technical College

Introduction to Industrial Maintenance

INMT 1305

Basic mechanical skills and repair techniques common to most fields of industrial maintenance. Topics include precision measuring instruments and general safety rules common in industry, including lock-out/tag-out.

Electricity Principles

CETT 1402

This course is a study of the principles of electricity including proper use of test equipment, A/C and D/C circuits, and component theory and operation. Topics covered include introductions to Ohm's law, Kirchoff's laws, networks, transformers, resonance, phasors, and capacitive, inductive, and circuit analysis techniques. All material will be reinforced with laboratory activity.

Recommended Products:

Machinery Installation

INMT 2301

Students utilize skills acquired in previous studies. Machinery foundation, locations, installation, and alignment activities are practiced and tested. Emphasis is on the various methods of shaft alignment including laser shaft alignment.

Industrial Mathematics

TECM 1301

Introduction to mathematical applications utilized to solve problems in the manufacturing field. Topics include fractions, decimals, percentages, simple equations, ratio and proportion, unit conversions, and applied geometry and trigonometry.

Manufacturing Processes

INMT 1419

Exploration of a variety of methods used in manufacturing. Theory and application of processes including but not limited to metal forming, welding, machining, heat treating, plating, assembly procedures, and process control considerations, casting and injection molding.

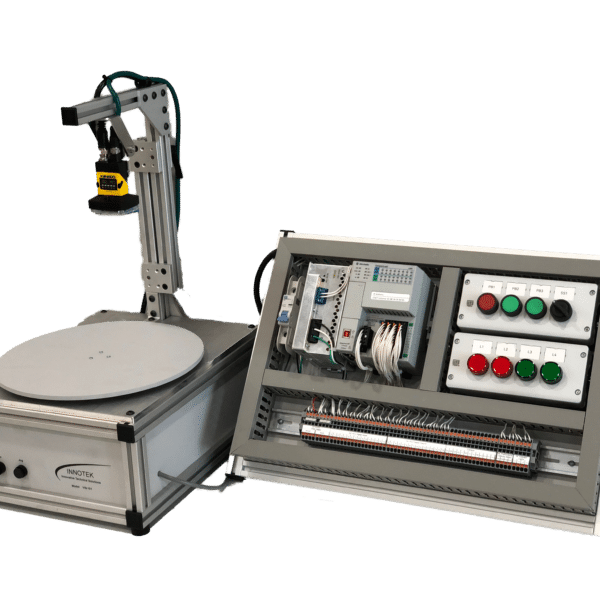

Robotic Fundamentals

RBTC 1305

This course provides an introduction to flexible robots/automation. Topics include installation, repair, maintenance, and development of flexible robotic manufacturing systems

Recommended Products:

Hydraulics and Pneumatics

HYDR 1345

Discussion of the fundamentals of hydraulics and pneumatics, components of each system, and the operations, maintenance, and analysis of each system.

Recommended Products:

Piping Standards and Materials

PFPB 2308

Identification, description, and application of piping standards and specifications. Includes identification and use of various metallic and non-metallic piping materials, identification and installation of valves, and material take-offs.

Programmable Logic Controllers I

ELPT 2319

Fundamental concepts of programmable logic controllers, principles of operation, and numbering systems as applied to electrical controls.

Recommended Products:

Pumps, Compressors, & Mechanical Drives

INMT 2303

A study of the theory and operations of various types of pumps and compressors. Topics include mechanical power transmission systems including gears, v-belts, and chain drives.

Introduction to Automated Manufacturing

MFGT 1302

Application of electromechanical systems. Emphasizes programmable control devices and solid state systems.

Instrumentation Systems

INTC 2333

This course covers synthesis, application, and integration of instrument

installation components and includes a comprehensive final project.

Recommended Products:

Motors and Transformers

ELPT 2305

A study of the principles of operation of single and three phase motors and transformers. Topics include transformer banking, power factor correction, and protective devices.

Air Conditioning Control Principles

HART 1403

A basic study of HVAC and refrigeration controls; troubleshooting of control components; emphasis on use of wiring diagrams to analyze high and low voltage circuits; a review of Ohm's law as applied to air conditioning controls and circuits

Electromechanical Devices

RBTC 1347

A study of electro-mechanical devices found in robotic systems. Includes transformers, switches, and solid state relays. Students will install wiring for electro-mechanical applications; analyze transformer applications; and troubleshoot related electrical components found in automated systems.

Industrial Troubleshooting

INMT 2345

An advanced study of the techniques used in troubleshooting various types of industrial equipment to include mechanical, electrical, hydraulic, and pneumatic systems and their control devices. Emphasis will be placed on the use of schematics and diagrams in conjunction with proper troubleshooting procedures. Students will successfully complete the NCCER Certification in Rigging Fundamentals. This is a capstone course for the Associate of Applied Science in Industrial Mechanics Technology.

Recommended Products:

Computer Integrated Manufacturing

RBTC 2347

The principles of computer integrated manufacturing, including case studies and implementation of process control techniques, CAD/CAM, operations, software, and networking for CIM systems.

Recommended Products:

Special Topics in Manufacturing Technology

191

Topics address recently identified current events, skills, knowledge, and/or attitudes and behaviors pertinent to the technology or occupation and relevant to the professional development of the student. This course may be repeated if topics and learning outcomes vary.

Recommended Products:

See how toolkit can help your program

Reach out to our sales team to see how we can help your program succeed like many others. we have mobile showrooms in demos available in many parts of the country.

Sales

sales@toolkittech.com

(512) 203-0590

General

info@toolkittech.com