Manufacturing

Showing 1–12 of 33 results

-

Niryo 6-Axis Training Robot

Discover our Niryo tabletop 6-axis robots for training, education, and research.

The first 6 axis desktop robotic arm inspired by industry 5.0 – Start Training for the Future Today!

The Niryo Ned2 is an educative solution for everyone who wants to teach or learn through robotics.

The robot is inspired by industry, and includes robust curriculum, manuals and activities for all levels of learners to get practical career and technical education training.

-

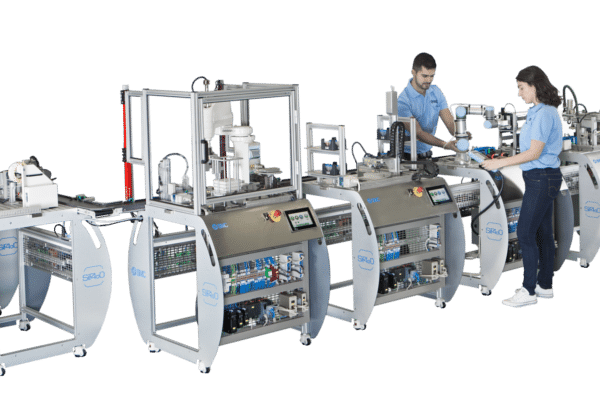

SMC Smart Innovative Factory Training System

Take a look at the most remarkable, fully-connected Industry 4.0 Training Platform on the market for hands-on training, exploration, and research in advanced manufacturing industries: SMC’s SIF-400.

SMC’s Industry 4.0 Smart Innovative Factory reproduces an industrial, cyber-physical smart factory – in both production applications and supply chain applications – for a school to provide real-world advanced manufacturing training. The training system is a modular design comprised of 14 interconnected stations for hands-on training and research of connected systems, operational data and data analytics, IIoT, predictive and preventative maintenance, management execution software (MES), inventory tracking and control, cybersecurity, and more.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

SMC Mechatronics + Industry 4.0 Learning System (M&I-400)

The newest training system for developing skills in both Mechatronics and Industry 4.0 technologies.

SMC’s M&I-400 is a learning system designed for training on industrial technologies in mechatronics and industry 4.0, while being incredibly attractive and visually appealing. The industrial system makes it easy for students to attain industry’s most needed skills through exciting and practical activities, while also attracting students to learn these skills and technologies.

Projects and activities can be carried out that motivate students to explore Industry 4.0 concepts and technologies while also learning important fundamental concepts related to Mechatronics.

SMC’s M&I-400 emulates a highly automated factory, where different types of products are produced, packed and shipped. The M&I-400 training system makes it possible to work on advanced and connected manufacturing concepts.

This system is aligned with SMC’s Industrial Certification Pathway for Industry 4.0.

-

SMC Flexible Manufacturing System – Industry 4.0

The best just got better with this incredible training from SMC! SMC’s FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market for mechatronics and industrial troubleshooting training and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training.

The SMC Flexible Manufacturing System is used by countless companies and schools across the globe for real industry training.

-

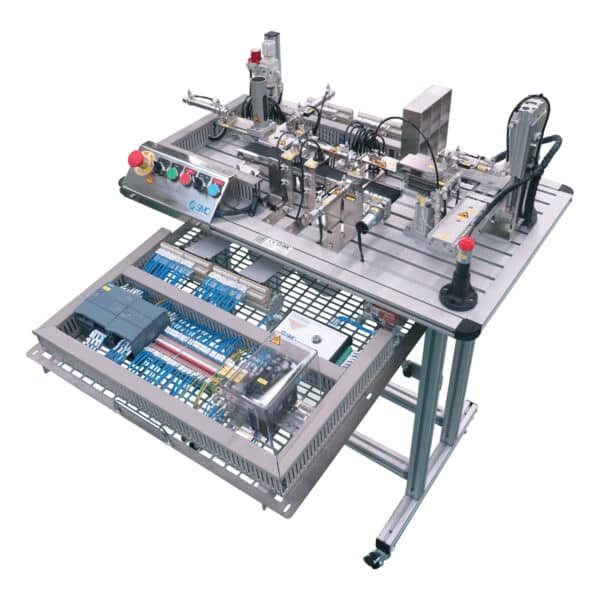

SMC Compact Automation Training System (Automate-200)

SMC’s exciting compact training system for Automation and Mechatronics, AUTOMATE-200, is the perfect training aid for students in advanced manufacturing classrooms for hands-on skills in PLC Programming, Sensors, Pneumatics, Troubleshooting, and More! Developed in partnership with Intel for training in the semiconductor industry, featuring all industrial SMC Components.

Designed for hands-on training in advanced manufacturing, semiconductor fabrication, and EV battery production, this system provides an integrated and industry-relevant environment for students to develop skills in automation, material handling, and process control. The training system simulates precision sorting, transfer, and classification of components, introducing learners to key technologies such as pneumatics, sensors, electric motors, and PLC programming—all critical in modern high-tech manufacturing.

Learners will work with industrial-grade automation equipment to experience real-world applications in component assembly, defect detection, and automated material handling. The system features:

- Vertical Part Feeder – Simulates precise material feeding for high-volume manufacturing lines.

- Platform with Part Detector – Detects and verifies components for sorting and process optimization.

- Conveyor Belt – Emulates automated material transport in semiconductor and battery production.

- Photoelectric Detector – Ensures quality control and part verification using optical sensing.

- Inductive Detector – Identifies and classifies metal components for process automation.

- Opening Detector – Monitors access points for secure and controlled material flow.

- Belt Pusher (Double-Acting Cylinder) – Demonstrates industrial part diversion for multi-stage manufacturing.

- Handling Device (Pneumatic Actuator / Rotary Actuator) – Trains students in robotic-assisted assembly and transfer operations.

- Part Classifier / Warehousing – Introduces students to automated storage and retrieval systems (AS/RS) used in high-tech manufacturing facilities.

This complete training solution includes all Student and Instructor Curriculum, plus:

✔ Rolling Cart for Mobility

✔ Allen-Bradley PLC or PLC of Choice for hands-on automation programmingIdeal for technical education programs, workforce development initiatives, and advanced manufacturing training labs, this system prepares students for careers in the fast-growing semiconductor, EV battery, and smart manufacturing industries.

-

Highly Automated Training System HAS-200

Train your students with the same Industry 4.0 training system used by companies like Intel and Boeing for their workforce training!

The HAS-200 SE i4o brings SMC’s industry leading technologies into a modular, customizable smart factory for education with training options in PLC programming, HMI programming, Management Execution Systems software, interconnected systems, smart devices, robotics, and more.

-

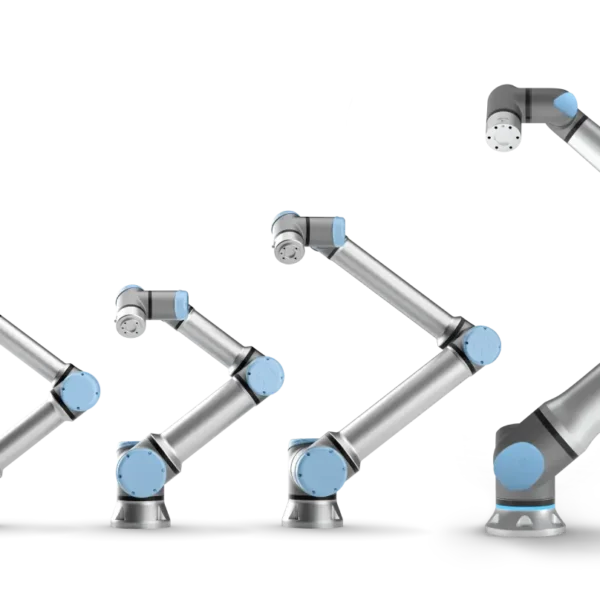

Universal Robots Collaborative Robots

Toolkit Technologies is proud to offer Universal Robots’ industry-leading collaborative robots to education and training institutions around the country.

Empower your students with cutting-edge industrial skills training solutions using Universal Robots’ collaborative robots. Our hands-on training systems, featuring all-industrial technologies sourced from industry leaders like SMC, UR, Miller Electric, and others, immerse learners in real-world applications that prepare them for dynamic careers in today’s tech-driven workforce.

Elevate your educational programs with our state-of-the-art robotics technology, fostering innovation and expertise in your students. Explore our range of training solutions now for comprehensive technical education solutions that drive future success.

We are proud to offer robust curriculum, eLearning, on-site training, and custom training applications with every UR Robot.

Let us know what robotics application you want to teach, and we’ll build it!

-

Electronics Training Boards

We are excited to introduce our newly enhanced and versatile electrical training solution, designed specifically for Aviation, Electronics, Semiconductor, and Manufacturing classrooms.

This cutting-edge trainer offers comprehensive capabilities in Analog, Digital, and Aviation electronics, empowering learners to explore every facet of electrical technology through hands-on engagement. Its thoughtfully engineered design keeps all tools, systems, and resources within easy reach, fostering a seamless and interactive learning experience.

Featuring core electrical units paired with modular electronic panels, this system provides targeted, in-depth exploration of specific technologies. Learners can easily navigate and master concepts with integrated measuring instruments and digital curriculum displayed conveniently at their workstation.

This innovative trainer is set to redefine how electrical technology is taught, making it an indispensable asset for the modern classroom.

-

SMC Fanuc Robot Training Cart

SMC’s Fanuc Robot Training System: Advanced Robotics Training for the FutureThe robot cart includes integrated compressed air with quick connect manifolds, LED stack light, pick and place training activities, warehousing and palletizing activities, path following, drawing and writing activities, and options for advanced training applications like production cells, machine tending, sensors and part identification and more!

The industrial design of the robot cart emulates real world industry experiences. The modular design with drop-in, quick-connect training application allows for easy expansion of training scenarios. The integrated electrical panel with din rails and panduit allows for students to further create, build, integrate and use various automation devices on one robot platform.

-

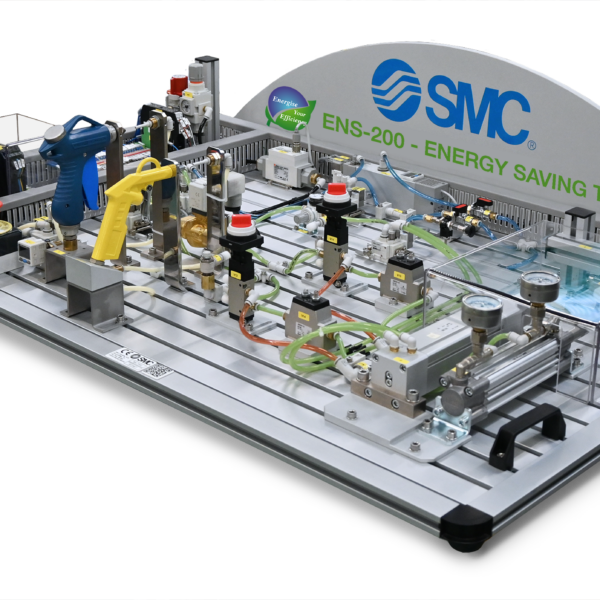

SMC Air Energy Savings Trainer

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed a state-of-the-art training system for teaching students about Sustainability, Energy Efficiency, Green Technologies, and Air Leakage.

The ENS-200 integrates a series of applications (vacuum, actuators and blowing) aimed at getting technicians to understand and implement the proper procedures and standards associated with energy saving in compressed air installations.

Modern Manufacturing needs to be green and companies are adopting these green energy conservation technologies and techniques, so let’s train students to be prepared.

The ENS-200 teaches you how to detect possible excessive consumption and suggest actions to prevent it. Users will analyze different scenarios through a series of guided activities. Each experiment shows how much has been saved, both as a percentage and in the chosen currency.

-

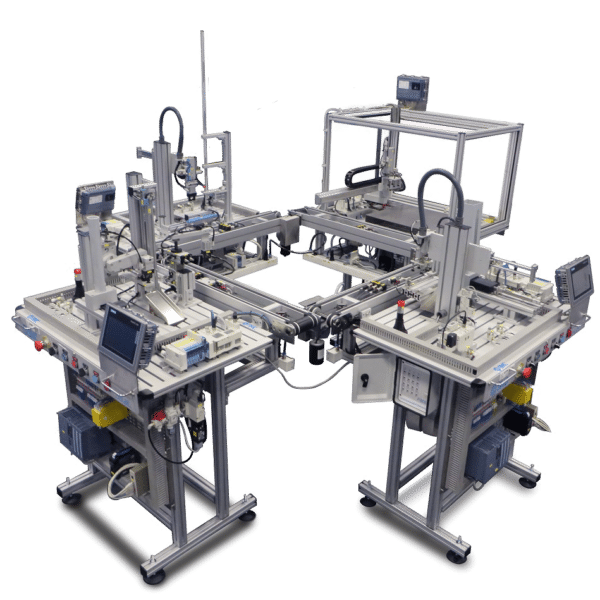

4-Station Flexible Manufacturing System i4o

The best just got better with this incredible training from SMC! The FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training for industry.

The 4-Station Configuration brings classrooms a compact and expandable solution for hands-on Industry 4.0 training with built-in troubleshooting.

Students will get industry-relevant hands-on training around the crucial skills demanded by manufacturing and industry. Industrial manufacturing skills student expect to receive include automation processes, safety, PLC programming, Distributed IO, smart devices, artificial vision, and more!

-

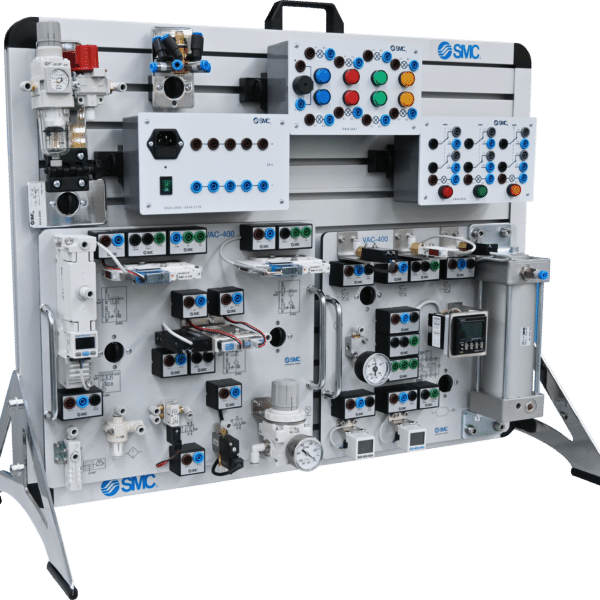

SMC Vacuum Technology Training System

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed a training system specifically for hands-on skills development in Vacuum Technology. Featuring the most commonly found vacuum technologies found in industrial companies like Intel, Dell, Apple, Samsung, Toyota, and more, the VAC-400 is the training system needed for skills development training in vacuum technologies.