Automotive Technology

Explore Toolkit’s solutions for Automotive Technology Training Systems for modern automotive classrooms.

The ever-increasing quantity of technologies found in modern vehicles, combined with the ever-increasing complexity of electronic systems and state-of-the-art technologies such as Advanced Driver Assistance Systems (ADAS), Smart Sensors, Autonomous Driving systems, Interconnected Systems, Computerized Diagnostic and Scan Tools, Plug-In Electric Vehicle and Hybrid technologies, etc. creates an increased need for automotive training to be done with modern, state-of-the-art technologies and training systems.

Modern Automotive Training Labs should keep pace with modern automotive vehicles on the road.

Automotive service technicians and mechanics can be expected to:

- Identify problems, often by using computerized diagnostic equipment

- Plan work procedures, using charts, technical manuals, and experience

- Test parts and systems to ensure that they work properly

- Follow checklists to ensure that all critical parts are examined

- Perform basic care and maintenance, including changing oil, checking fluid levels, and rotating tires

- Repair or replace worn parts, such as brake pads, wheel bearings, and sensors

- Perform repairs to manufacturer and customer specifications

- Explain automotive problems and repairs to clients

Although service technicians work on traditional mechanical systems, such as engines, transmissions, and drivebelts, they also must be familiar with a growing number of electronic systems. Braking, transmission, and steering systems, for example, are controlled primarily by computers and electronic components.

Other integrated electronic systems, such as accident-avoidance sensors, are becoming common as well. In addition, a growing number of technicians are required to work on vehicles that use electricity or alternative fuels, such as ethanol.

Service technicians use many different tools, including computerized diagnostic tools and power tools such as pneumatic wrenches, lathes, welding torches, and jacks and hoists, in addition to common hand tools like wrenches, pliers, and sockets.

Whether for transportation and logistics classrooms, agriculture and mechanics or manufacturing classrooms, Toolkit has the Automotive Service Technology Training Systems and ASE Certification-aligned solutions to fit your area’s industry training needs.

Job Outlook: 69,000 new jobs per year

Average Pay: $46,890

Shop by ASE Category

Showing all 10 results

-

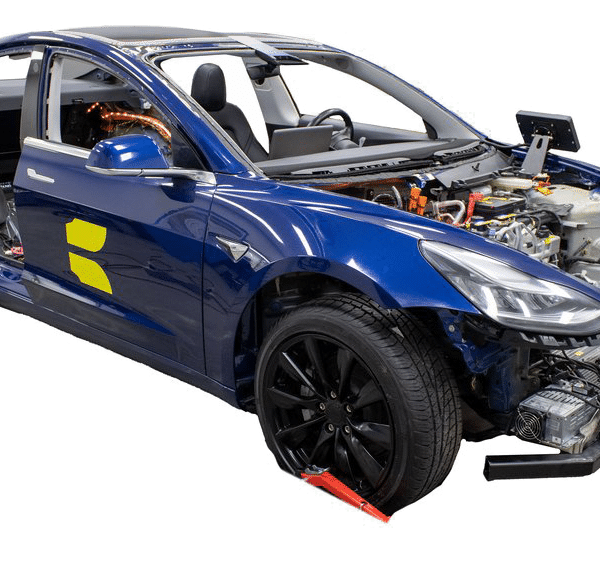

Tesla Electric Vehicle Training System

The ConsuLab EV-601-TS is a fully functioning Electric Vehicle Training System based on the Tesla Model 3 Platform. What better way to teach all things EVs than on the world’s leading electric vehicle manufacturer, Tesla.

We are proud to release premier Electric Vehicle Training System available on the market today, the ConsuLab EV-601 iDEV Tesla Training Car. Featuring a functional Tesla Model 3 with OEM components and technologies.

Have you ever wondered how to give your students hands-on exploration of a complete electrical vehicle in a safe environment? The EV-601-TS_053322 ALL EV iDEV training car by ConsuLab is not just a training aid, it’s an actual Tesla Model 3 training car visually displayed for maximum learning! All major components are identified in their actual location, most have been exposed (cutaway) in a way that is not possible on an operating vehicle, this helps attain a better understanding of their internal components and workings.

Complete with practical training activities and curriculum!

-

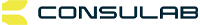

EV High Voltage Safety and Disconnect Trainer

We are proud to announce our newest training system for Automotive and Electric Vehicle classrooms, the EV-400 High Voltage Safety and Disconnect Trainer from ConsuLab.

EV-400: Mastering Electric Vehicles in a Safe, Interactive Environment

The EV-400 is a groundbreaking interactive high voltage trainer designed to revolutionize the way we teach and learn about electric vehicle (EV) systems. This premier tool goes beyond mere demonstrations, empowering students to actively test, explore, and diagnose real-world EV scenarios in a completely safe environment.Combining fundamental and foundational skills in electrical concepts with EV-specific training content in high voltage circuits and first-responder loops, the EV-400 is a must-have training tool for modern automotive classrooms. With over 90 testable functions, the EV-400 allows students to hone diagnostic skills with a built in fault box emulating common EV High Voltage issues. It’s not just about demonstration; it’s about active engagement, hands-on learning, and real-world application.

The system provides students hands-on learning in high voltages, EV isolation practices, and gives students safe and effective access to MEASURABLE 400V high voltages.

Available in single training systems or as classroom packages of 12 training systems.

-

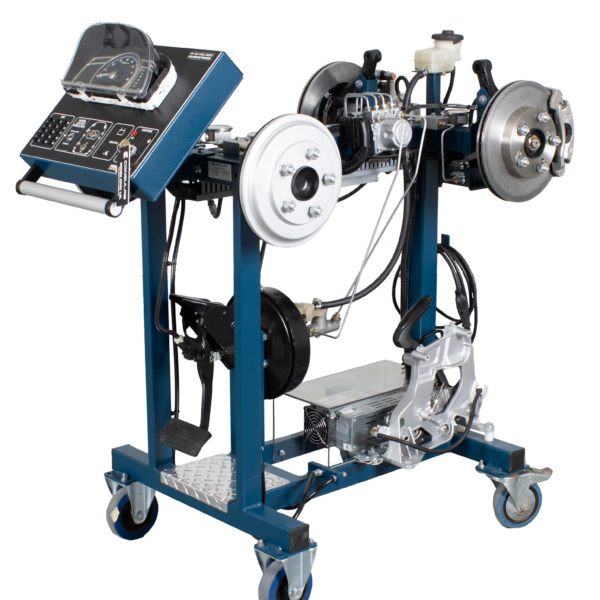

Four-Wheel Honda ABS Trainer with Faults

ConsuLab’s EM-122-HN02 Four-wheel Honda ABS trainer is used to demonstrate the functionality of the ABS braking system as it operates on a real vehicle. This automotive training aid includes mechanical faults in the friction components, which are designed to be diagnosed by students while performing a brake inspection.

This trainer also comes with six insertable, electronic faults, and is built with OEM components based on the 2006-2010 Honda Civic platform. The trainer can be used in the classroom environment for demonstrations to students.

The instructor can manually select which wheel combinations are desired to lockup prior to application of brake pedal. The trainer provides a safe and effective method of demonstrating the principles of braking systems used on today’s vehicles.

All routine brake service procedures can be performed on this trainer including component replacement, adjustments and hydraulic bleeding

-

Two-Wheel Hydraulic Brake Trainer (Non-ABS)

The Consulab Two Wheel Hydraulic Brake System Trainer EM-123-2_053251 is a 2-wheel hydraulic brake system trainer that is used to demonstrate the functionality of a typical non-ABS braking system as it operates on a real vehicle.

The trainer is built with OEM components and is based on the non-ABS Honda Civic platform. The trainer can be used in the classroom environment for demonstrations to students. The trainer provides a safe and effective method of demonstrating the principles of hydraulic braking systems used on today’s vehicles.

This brake trainer is made to order and comes complete with curriculum and student activity manuals.

-

4-Wheel Hydraulic Brake Trainer with Disc and Drum + Faults

The ConsuLab EM-123-4HN02 Disc & Drum Brake Trainer with Faults is used to demonstrate the functionality of a modern automotive hydraulic braking system as it functions on vehicle.

The inclusion of four permanent, mechanical, real-world faults captures students attention and proves their learning. The product is built using recycled OEM components for the platform and all wear items are brand new (discs, pads, drums, shoes, etc.).

The EM-123-4HN02 Disc and Drum Brake training aid has an extremely small footprint and can fit into any classroom, even your office for robust automotive training anywhere! It fits through a 30″ door.

All routine brake service procedures can be performed on this trainer including:

• Master cylinder service

• Brake pad/shoe replacement

• Disc/Drum service

• Wheel bearing service

• Caliper/Wheel cylinder service

• Brake hose/line service

• Parking brake service -

Relay Lab Kits Pro

This hands-on learning tool from Switch Labs is designed to teach the functions and wiring of relays, switches, and lights while preparing students to wire up the dash on a Switch EV Kit Car. Includes 5 – 100-foot spools of wire, ferrule connectors, instructions, schematic and testing procedure.

-

Hybrid Planetary Gearset Trainer

The ConsuLab EM-200-29 Hybrid Planetary Gear-Set Trainer is designed to help instructors teach and students to understand the somewhat complex operation of a typical hybrid vehicle drivetrain. Based on a typical Toyota Prius hybrid vehicle, the trainer provides easy visualization of driveline component operation including:

- ICE (Internal Combustion Engine)

- MG1 (Motor/generator # 1)

- MG2 (Motor/generator # 2)

- Drive wheels

-

Cutaway Toyota Prius Hybrid Drive Train

The EC-140H Cutaway Toyota Prius Hybrid Drive Train is a training system designed specifically for teaching how a typical hybrid drive train operates. The trainer consists of all cutaway drive train components from a Toyota Hybrid Synergy Drive system including:

- ICE (internal combustion engine)

- Torque damper assembly

- MG1 (motor/generator #1)

- Planetary gearset (power split device)

- MG2 (motor/generator #2)

- Transaxle

- Inverter

- HV (high voltage) battery (non-functional)

The ICE, MG1, MG2 and differential output/drive wheels are driven with external electric motors via connecting chains. This design allows the demonstration of eight of the possible hybrid operating modes. All components are cutaway to allow clear student visual learning.

-

Cutaway Active Brake Booster and Master Cylinder

The ConsuLab EC-122 cutaway allows to visually demonstrate the operation and internal parts of a vacuum brake booster and master cylinder. The trainer is equipped with a braking handle that simulates the brake pedal for educational purposes. On a vehicle when the driver depresses the brake pedal, the movement is transformed into hydraulic pressure that is delivered to hydraulic cylinders at the four wheels through pipes and hoses using an incompressible fluid.

-

Cutaway 30/30 Air Brake Chamber

The EC-127 Cutaway 30/30 Air Brake Chamber is partly cut away so that a trainee can observe the internal elements housed within the chamber.

Made to Order.