Automotive Technology

Explore Toolkit’s solutions for Automotive Technology Training Systems for modern automotive classrooms.

The ever-increasing quantity of technologies found in modern vehicles, combined with the ever-increasing complexity of electronic systems and state-of-the-art technologies such as Advanced Driver Assistance Systems (ADAS), Smart Sensors, Autonomous Driving systems, Interconnected Systems, Computerized Diagnostic and Scan Tools, Plug-In Electric Vehicle and Hybrid technologies, etc. creates an increased need for automotive training to be done with modern, state-of-the-art technologies and training systems.

Modern Automotive Training Labs should keep pace with modern automotive vehicles on the road.

Automotive service technicians and mechanics can be expected to:

- Identify problems, often by using computerized diagnostic equipment

- Plan work procedures, using charts, technical manuals, and experience

- Test parts and systems to ensure that they work properly

- Follow checklists to ensure that all critical parts are examined

- Perform basic care and maintenance, including changing oil, checking fluid levels, and rotating tires

- Repair or replace worn parts, such as brake pads, wheel bearings, and sensors

- Perform repairs to manufacturer and customer specifications

- Explain automotive problems and repairs to clients

Although service technicians work on traditional mechanical systems, such as engines, transmissions, and drivebelts, they also must be familiar with a growing number of electronic systems. Braking, transmission, and steering systems, for example, are controlled primarily by computers and electronic components.

Other integrated electronic systems, such as accident-avoidance sensors, are becoming common as well. In addition, a growing number of technicians are required to work on vehicles that use electricity or alternative fuels, such as ethanol.

Service technicians use many different tools, including computerized diagnostic tools and power tools such as pneumatic wrenches, lathes, welding torches, and jacks and hoists, in addition to common hand tools like wrenches, pliers, and sockets.

Whether for transportation and logistics classrooms, agriculture and mechanics or manufacturing classrooms, Toolkit has the Automotive Service Technology Training Systems and ASE Certification-aligned solutions to fit your area’s industry training needs.

Job Outlook: 69,000 new jobs per year

Average Pay: $46,890

Shop by ASE Category

Showing 1–12 of 19 results

-

Suspension and Steering Trainer

The ConsuLab EM-130 Suspension and Steering trainer is designed to assist instructors in teaching basic alignment geometry and the function of a MacPherson strut suspension system with rack & pinion steering. The trainer is extremely versatile in that students can easily visualize all component operation as well as practice adjusting the various alignment angles. The trainer is equipped with two movable turntables and a magnetic alignment measuring gauge to assist students in observing actual measurement and changes in alignment angles. Students can also visualize and learn common braking system components.

-

Fuel Injection & Engine Management Trainer

The ConsuLab EM-330-1 Fuel Injection and Engine Management Trainer functions as in a real automobile, but uses non-flammable fluid instead of gasoline for safety and educational purposes. The trainer is used to teach and demonstrate engine management systems in a vehicle. The advantage to the trainer comes in the fact that it produces no exhaust, will fit through virtually any doorway, has adjustable inputs and is the actual system used on the vehicle.

-

Hybrid Planetary Gearset Trainer

The ConsuLab EM-200-29 Hybrid Planetary Gear-Set Trainer is designed to help instructors teach and students to understand the somewhat complex operation of a typical hybrid vehicle drivetrain. Based on a typical Toyota Prius hybrid vehicle, the trainer provides easy visualization of driveline component operation including:

- ICE (Internal Combustion Engine)

- MG1 (Motor/generator # 1)

- MG2 (Motor/generator # 2)

- Drive wheels

-

Cutaway Toyota Prius Hybrid Drive Train

The EC-140H Cutaway Toyota Prius Hybrid Drive Train is a training system designed specifically for teaching how a typical hybrid drive train operates. The trainer consists of all cutaway drive train components from a Toyota Hybrid Synergy Drive system including:

- ICE (internal combustion engine)

- Torque damper assembly

- MG1 (motor/generator #1)

- Planetary gearset (power split device)

- MG2 (motor/generator #2)

- Transaxle

- Inverter

- HV (high voltage) battery (non-functional)

The ICE, MG1, MG2 and differential output/drive wheels are driven with external electric motors via connecting chains. This design allows the demonstration of eight of the possible hybrid operating modes. All components are cutaway to allow clear student visual learning.

-

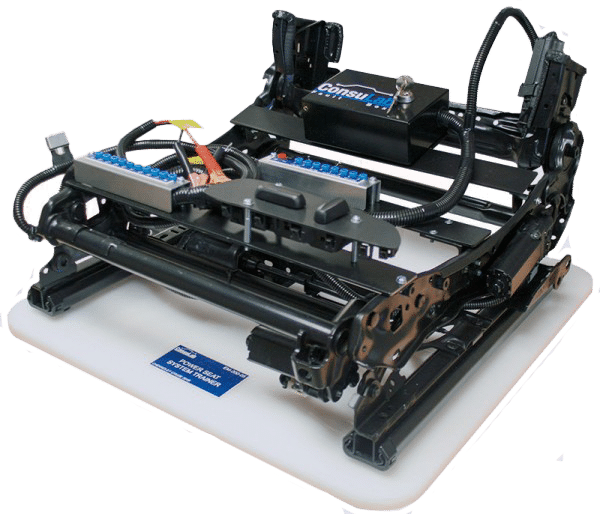

Power Seat System Trainer

The EM-200-05 trainer allows for the demonstration of a complete power seat system using real-world components. Terminal block receptacles are provided for diagnostic test points. Fault insertion included. The trainer requires a 12V power supply to operate.

-

Wiper & Washer System Trainer

The EM-200-06 trainer allows for the demonstration of a complete wiper and washer system using real-world components. Terminal block receptacles are provided for diagnostic test points. It includes the following:

- OEM Wiper motor

- Section of wiper transmission

- Washer fluid pump

- Wiper/washer switches

- Lockable fault box with 4 faults

- Test points for diagnosis

- Linkage enclosed in a clear plastic enclosure for safety

- Requires a 12VDC power supply to operate

-

Power Door Lock System Trainer – 4-Door GM

The EM-200-03D4C Four-door Power Door Lock System Trainer allows for the demonstration of a complete power window system using real world components. Terminal block receptacles are provided for diagnostic test points.

-

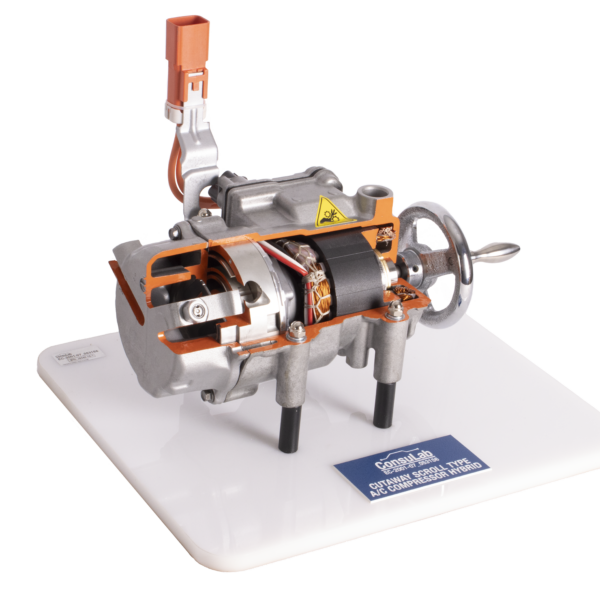

Cutaway Scroll Type A/C Compressor – Hybrid

Our EC-2001-07 is a cutaway training aid of a Scroll Type AC Compressor that allows students to see the internal operation of its electrically driven hybrid scroll type A/C compressor. The 3-phase electric motor that drives the compressor can be rotated using a hand crank.

-

Blower Motor System Trainer

The ConsuLab EM-200-11 trainer allows for the demonstration of a complete blower motor system using real-world components. Terminal block receptacles are provided for diagnostic test points. The trainer requires a 12V power supply to operate.Included Components:

- HVAC control module.

- Blower motor.

- Blower motor resistor.

- Fault box with 4 faults.

- Test points for diagnosis.

-

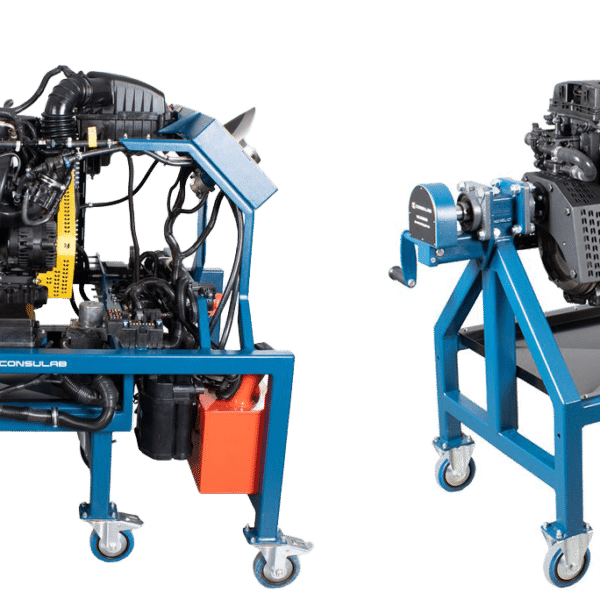

Engine Training Stand with Starting Station and 1.8L GM Chevy

The ConsuLab EM-145S-GM05 Engine Trainer with GM Chevy Sonic Ecotec engine on a swivel stand is designed for student instruction and practice covering engine mechanical inspection, disassembly, measurement and reassembly.

The working engine training system is securely mounted to a heavy duty rotating device equipped with an automatic lock to allow full 360 degree rotation. A steel mounting plate is used for engine mounting that allows full access for rear main seal and flywheel service. Each engine comes equipped with a transmission flywheel (manual or automatic).

The engine starting station contains all components and systems necessary for the starting and running of the Ecotec engine. All necessary engine systems connections are provided to allow live operation of each swivel engine stand.

-

Automotive Engine Trainer, Chevy Cruz 1.4L with Start/Stop + HVAC

The Engine Training Bench with Chevy Cruze 1.4-liter with Gasoline Direction Injection, Start/Stop technology, and A/C is ConsuLab’s first engine bench to ever have 2 pedals (brake and accelerator)!

It has two pedals so you can do stall tests and load the engine – you can perform a basic “road test” within your classroom going up to 20mph which allows STOP/START to function!

This automotive Engine Trainer also includes the new ConsuLink™ student learning platform that allows students and instructors to incorporate engine faults and case studies for immersive training in advanced drivability, diagnostics, engine performance and HVAC (air conditioning).

-

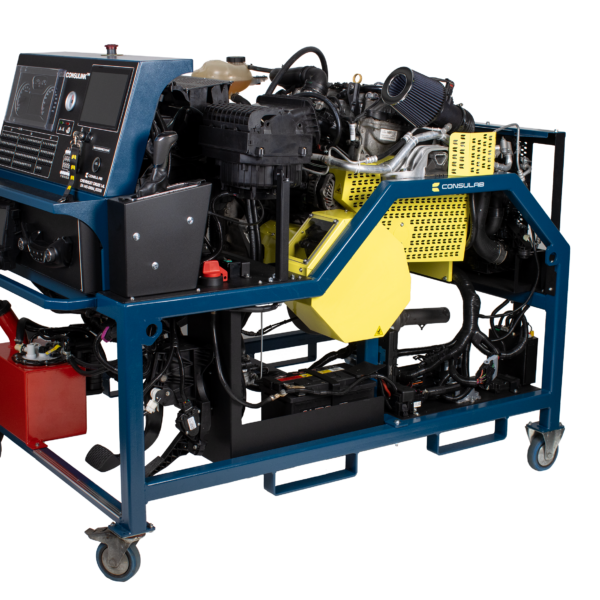

Automotive Engine Bench with Hyundai GDI 1.6L

The ConsuLab Engine Performance Trainer is an exciting new product that is designed for student-led learning on a real 2012-2017 Hyundai Accent 1.6L Gasoline Direct Injection Engine.

Experience the future of automotive engine training with the ConsuLab Automotive Engine Training System featuring the cutting-edge ConsuLink touchscreen interface. Our state-of-the-art system offers a hands-on learning experience like no other, empowering students and enthusiasts to explore the inner workings of engines with unprecedented ease and precision.

Students have access to case studies, operators manual, wiring diagrams, breakout boxes, schematics, videos and more right there on the engine.