Mechatronics

Showing 13–24 of 38 results

-

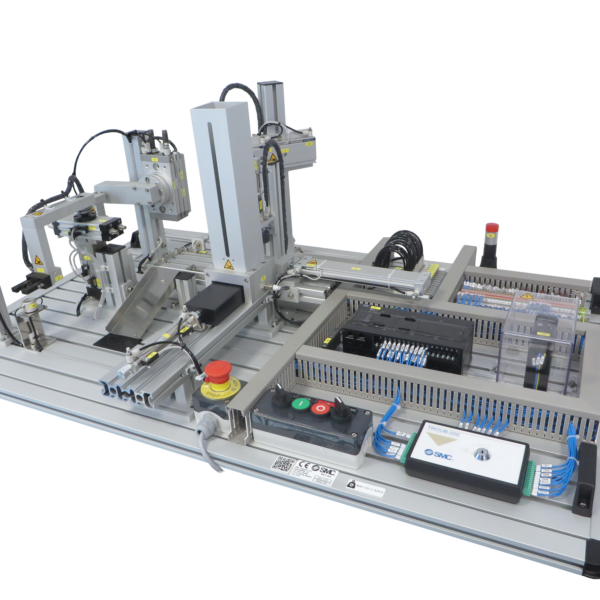

SMC Material Handling Training Systems

The MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-201: Body Supply Part Feeder + Detector/Ejector

MAP-202: Vacuum-Held Handling Device with Two Shafts

MAP-203: Vertical Revolving Handling Device with Internal Gripper of Bearing

MAP-204: Horizontal Rotolinear Handling Device with External Gripper of Shaft

MAP-205: Complete Mini-Cell Assembly

-

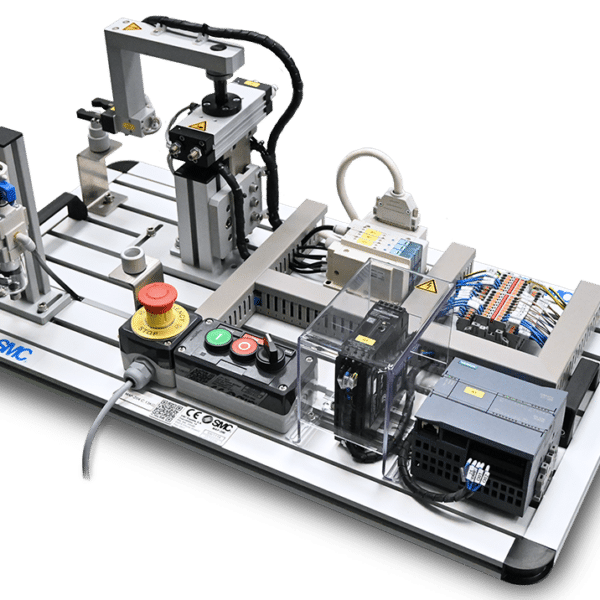

Part Feeding and Detecting Training System – MAP-201

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-201: Body Supply Part Feeder + Detector/Ejector

The process: A gravity feeder houses the parts in a column. Each part has a non-symmetrical interior housing and is ejected by a pneumatic cylinder. The correct orientation of the part is verified using a cylinder with a plunger. After verification, an oval section pneumatic cylinder moves the work-piece to the final position. Otherwise, a single acting cylinder removes the part via the evacuation ramp.

-

Vacuum-Held Material Handling Training System – MAP-202

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-202: Vacuum-Held Handling Device with Two Shafts

MAP-202: The function of this handling device is to transfer the part from a starting area to a final unloading area, using three vacuum pads. This is a cartesian handling device with two shafts which moves a part from one position to another, holding it with a set of three vacuum pads.

-

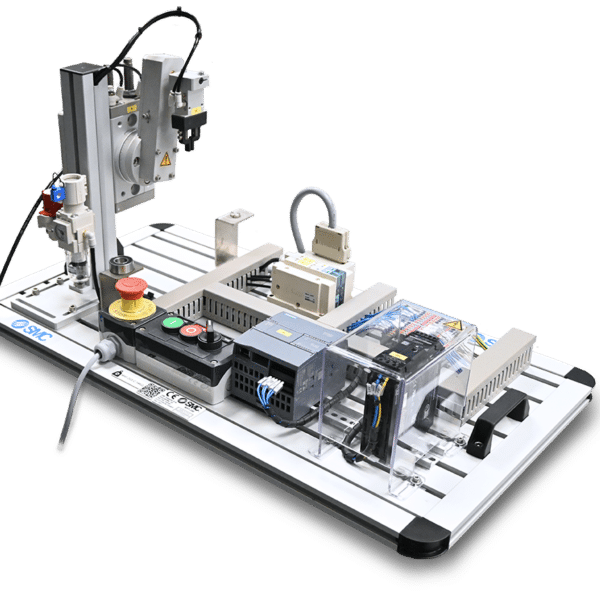

Vertical Revolving Material Handling Training System – MAP-203

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-203: Vertical Revolving Handling Training System with Internal Gripper

The function of this material handling device is to transfer the part from a starting area to an unloading area, using an internal gripper. The part used in this process is a bearing so that when it is placed on the unloading area, it fits perfectly onto a stainless steel pivot with a slightly smaller diameter than the bearing’s inner diameter.

-

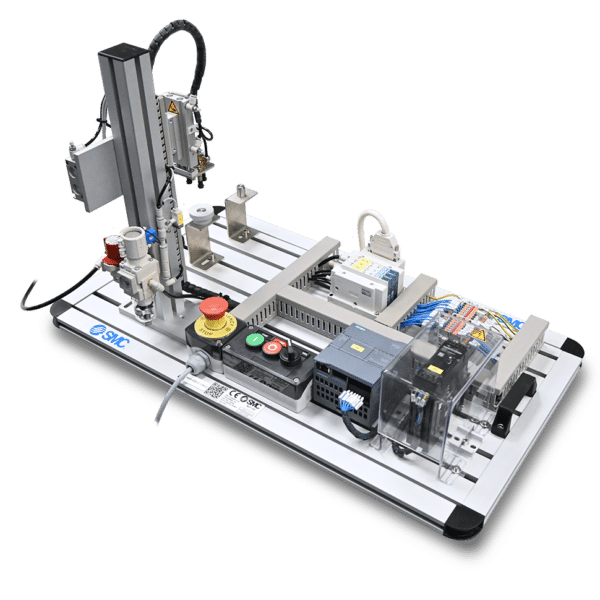

Horizontal Rotolinear Material Handling Training System – MAP-204

SMC’s MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

MAP-204: Vertical Revolving Handling Training System with Internal Gripper

The function of the handling device is to transfer the part from a starting area to an unloading area through a rotolinear actuator that displaces an outer gripper. The part being transported is a metal bearing.

The part used is made from anodized aluminum, 14.6mm diameter and 41mm height, so that when the part is placed on the unloading area it fits perfectly onto a stainless steel pivot with a slightly larger diameter than the shaft.

-

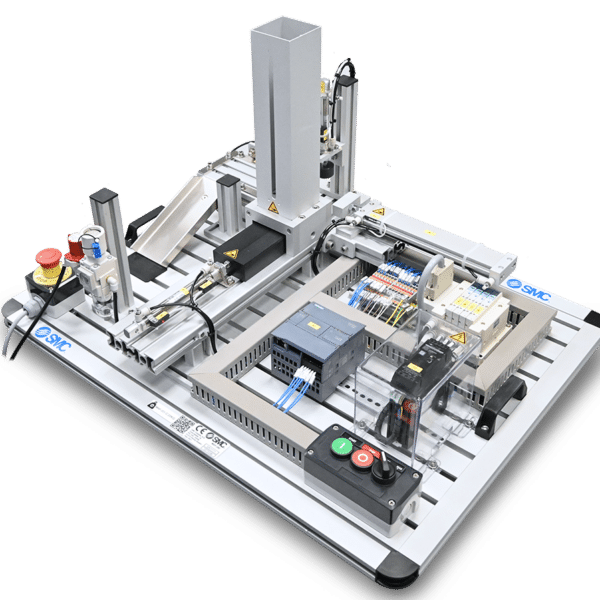

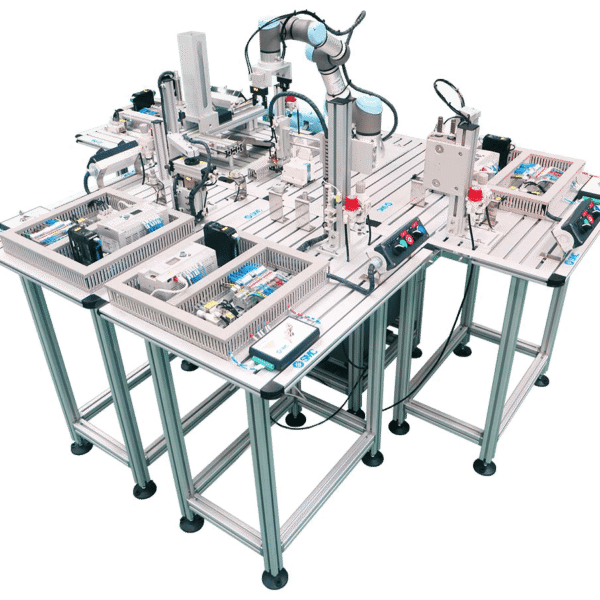

Mini-Cell Material Handling Assembly MAP-205

The MAP-200s consist of a series of individual tabletop mechatronics training systems that carry out a specific and different material handling task commonly seen in industrial settings.

Robust, Rugged, and Versatile, these tabletop hands-on training systems are designed to teach students a wide array of industrial automation – Pneumatics, Electrical, Industrial Safety and Automation Processes, PLC Programming, Sensors, and Troubleshooting!

The MAP-205 combines the MAP-201, MAP-202, MAP-203, and MAP-204 into a single integrated mini-cell assembly.

The MAP-205 assembles and disassembles a product (metal turning mechanism) via 4 handling devices working together on a single tabletop frame.

- Feeding the base

- Assembling the bearing

- Inserting the shaft

- Placing the lid

-

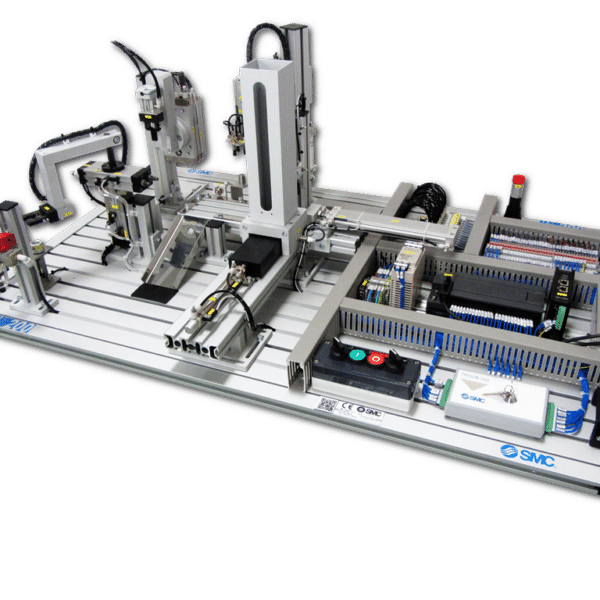

Modular Assembly System MAS-200

Build upon your mechatronics and automation studies with the MAS-200 Modular Assembly System from industry-leaders at SMC.

This hands-on training system emulates a real industrial assembly process, incorporating the major technologies required by today’s automated industry into one, compact system.

The complete system consists of five stations that work both independently and in unison to assemble a complete product with a metal base, bearing, shaft and lid. The fifth station is located between the others and is responsible for transferring and assembling the parts; which can be done via a pneumatic assembly or robotic assembly.

The modular design of the equipment allows a vast range of options since the stations are completely autonomous, but can be assembled to form a complete manufacturing cell.

MAS-201: Base Feeding Station

MAS-202: Bearing Insertion Station

MAS-203: Shaft Insertion Station

MAS-204: Lid Positioning Station

MAS-205: Transfer and Assembly Station – Robotic or Pneumatic

-

Motor Troubleshooting Training System

The MTS-101 Motor Troubleshooting System provides hands-on hardware for the development of skills and assessment of motor troubleshooting principals. Learners will utilize test equipment including an ohmmeter and megohmmeter to determine the condition of a 3-phase AC motor.

Insertable Faults are included on the side of the training system to allow for practical troubleshooting and testing to take place.

-

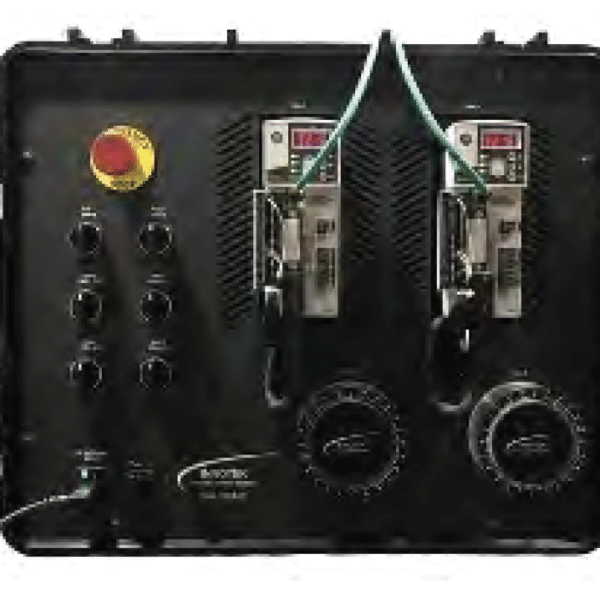

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

Conveyor and Logistics Automation Training System

The Conveyor and Logistics Automation Training System with Troubleshooting is our industrial training solution for school and companies looking for practical and realistic hands-on training activities in areas such as Maintenance, Troubleshooting, and Programming of industrial automation technologies commonly seen in warehouses, logistics settings, and industrial automation factories.

The mobile and modular system includes choices of PLC controller, Variable Frequency Drive, HMI’s, and conveyors. Conveyors stations can include: flatbed slider belt conveyors, roller bed belt conveyors, powered roller conveyor, plastic mesh conveyor, and more.

Up to 32 Troubleshooting Faults can be incorporated so students can troubleshoot and repair faulted components.

-

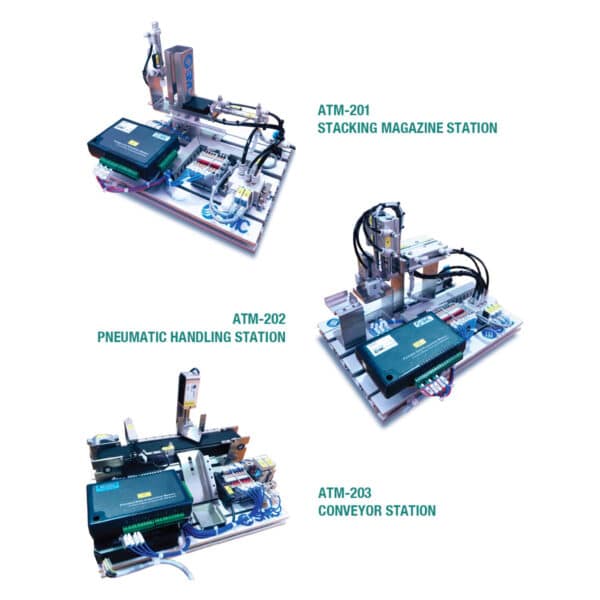

SMC Tabletop Automation Training Modules with PLC

New Training Product for engineering, automation and mechatronics classrooms!

Unlock the potential of your engineering, automation, and mechatronics classrooms with our cutting-edge SMC ATM-200 training system, now featuring Allen Bradley PLCs.

What sets the SMC ATM-200 apart is its versatility and functionality. Comprising three tabletop training aids, each equipped with a state-of-the-art data acquisition module, students gain practical experience in control and simulation using SMC’s autoSIM-200 software. But that’s not all – with an integrated Allen Bradley Micro800 PLC, learners can seamlessly transition to industrial programming using Rockwell Automation’s Connected Components Workbench.

With the SMC ATM-200, students delve deep into fundamental logic and control principles through autoSIM-200 before harnessing the full potential of an industrial processor with the PLC. From mastering electricity and pneumatics to honing programming skills and understanding sensor technologies, our training system offers a comprehensive curriculum that prepares students for real-world challenges in the manufacturing sector.

Each training module includes three tabletop training stations and a site license to access the autoSIM simulation software. This allows for virtual training in essential areas such as pneumatics, electrical circuits, hydraulics, and control systems, ensuring that every student has the tools they need to succeed.

Empower your students with the skills and knowledge they need to thrive in today’s competitive job market. Invest in the SMC ATM-200 and watch as your classroom becomes a hub of innovation, creativity, and hands-on learning in the exciting world of manufacturing.

-

SMC Tabletop Intro to Automation Training Modules (ATM-200)

SMC’s tabletop intro to Automation Training Module, ATM-200, is the perfect training system for high school automation, mechatronics, and exploratory career pathways. Learn and acquire hands-on skills in electricity, pneumatics, programming, sensors, and more!

Each training module consists of (3) tabletop training stations and site license to autoSIM simulation software for virtual training in pneumatics, electrical, hydraulics, and control circuits.