Manufacturing

The need for skilled, qualified, and capable manufacturing workers across the globe, especially here in the US, is one that will continue to rise for the foreseeable future.

Toolkit Technologies is focused on bringing the needed technologies, curriculum, and digital solutions to schools across the country that will train the next generation of manufacturing professionals and leaders.

Our manufacturing training solutions range from integrated mechatronics systems to electrical, sensors, mechanical, fluid power, robotics and more.

Our goal is clear and consistent: to train the future leaders of industry on the leading technologies from industry.

Showing 1–12 of 16 results

-

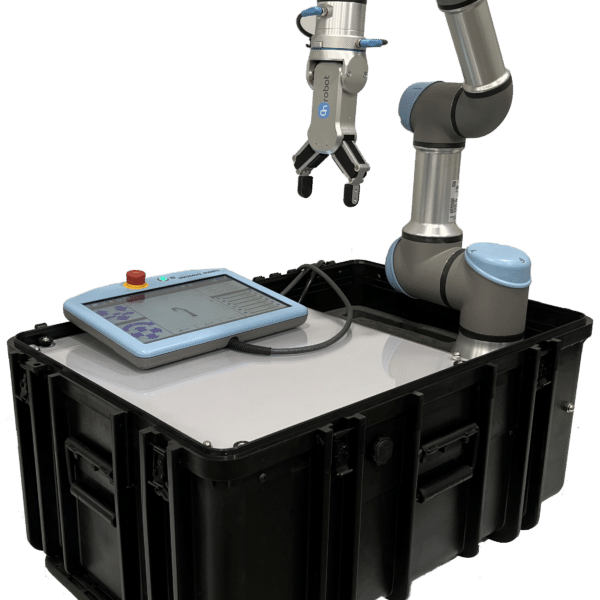

SMC Robot Training System RTS-200

SMC is proud to bring this one-of-a-kind Robot Training Platform to schools for real world robot training!

The RTS-200 training system provides participants with a hardware platform for performing hands-on development for robotic operations. The mobile platform includes various applications which can be quickly installed to provide advanced activities, expanding the learning objectives beyond simple pick and place functions. The design allows participants to advance from basic programming to integration of various technologies including electrical controls, pneumatics, controllers, artificial vision, sensors and more – all with simple drop-in training panels.

Have multiple robots? The RTS-200 allows for multiple robot models and brands to be dropped in as well!

SMC’s Partnership with Universal Robots allows students to get real-world certification on Universal Robots!

-

Universal Robot Suitcase Robot Training System

Toolkit Technologies is proud to bring this one-of-a-kind Robot Training Platform to schools for real world robot training!

The RTS-100 combines the modularity and industrial training capabilities of our RTS-200 Robot Training Cart with the advantages of a portable and compact, rugged suitcase form factor. This allows for easy and safe transport to remote training locations, satellite campuses, recruiting events and more. Additionally, the rugged and compact storage case allows for your robot training systems to be easily stored when not in use. Classrooms limited on space particularly enjoy the compact footprint of the RTS-100.

Toolkit’s Portable Robot Training System includes the controller, workpieces, training activities, curriculum, and all required components for successful robotics training. Foam inserts allow for safe and organized storage for all components and workpieces.

The RTS-100 is a great choice for providing industrial training activities around the Universal Robot UR3e, while giving you the flexibility and redeployment advantages of a mobile and portable training system. Reach out for alternative robot options such as Mecademic, uFactory, and more!

-

Hand Tools Fundamentals Training Bench

TOOLKIT’s Hand Tools Fundamentals Training System is a versatile foundational training package key to careers in the modern Construction industry.

Paired with hands-on lab activities, this courseware will help to teach students fundamental concepts in measurement, cutting, power tools, fasteners, hand tools, material handling, workplace and soft skills, etc.

The optional workbench provides additional storage capabilities and doubles as a student activity platform.

-

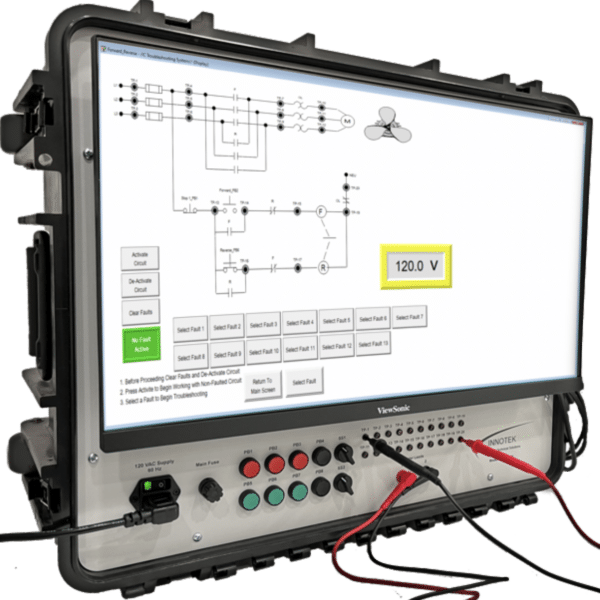

Electrical Troubleshooting System

We are excited to take your students’ and employees’ industrial troubleshooting skills to a whole new level with our Innotek Electrical Troubleshooting System, ETS-101.

The Electrical Troubleshooting System provides a hardware solution that introduces the fundamentals of troubleshooting electrical circuits in a sleek, portable, and approachable manner.

The unit is completely integrated into a portable suitcase allowing for easy transport. The unit provides circuits that are used in industrial applications, allowing participants to perform develop systematic troubleshooting skills.

Users can choose their electrical troubleshooting focus area and the circuit for students to troubleshoot.

-

Conveyor and Logistics Automation Training System

The Conveyor and Logistics Automation Training System with Troubleshooting is our industrial training solution for school and companies looking for practical and realistic hands-on training activities in areas such as Maintenance, Troubleshooting, and Programming of industrial automation technologies commonly seen in warehouses, logistics settings, and industrial automation factories.

The mobile and modular system includes choices of PLC controller, Variable Frequency Drive, HMI’s, and conveyors. Conveyors stations can include: flatbed slider belt conveyors, roller bed belt conveyors, powered roller conveyor, plastic mesh conveyor, and more.

Up to 32 Troubleshooting Faults can be incorporated so students can troubleshoot and repair faulted components.

-

Motor Troubleshooting Training System

The MTS-101 Motor Troubleshooting System provides hands-on hardware for the development of skills and assessment of motor troubleshooting principals. Learners will utilize test equipment including an ohmmeter and megohmmeter to determine the condition of a 3-phase AC motor.

Insertable Faults are included on the side of the training system to allow for practical troubleshooting and testing to take place.

-

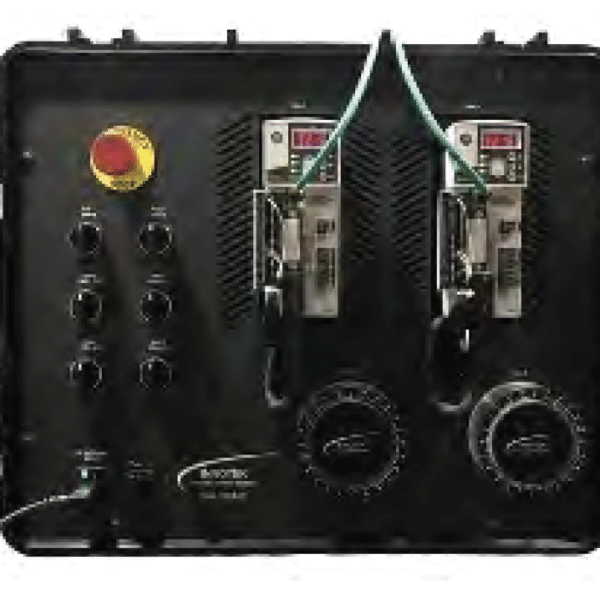

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

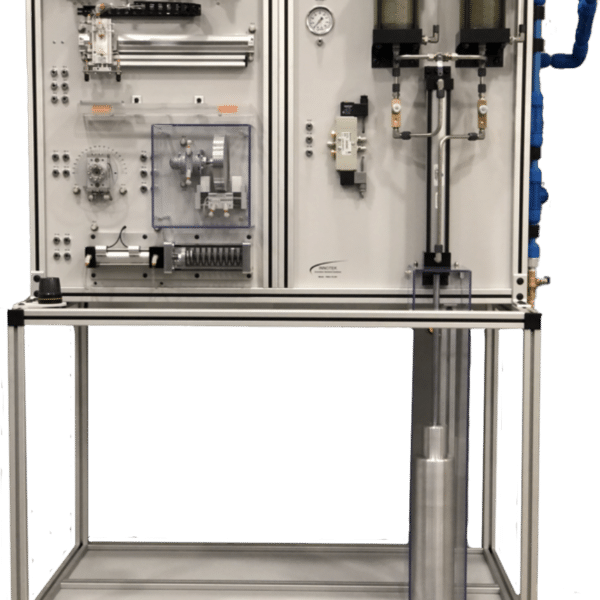

Pneumatic Troubleshooting Training System

Take your Pneumatics training to the next level with our new, hands-on Pneumatic Troubleshooting Training System.

The PNEU-TS-201 Training system provides participants with hardware allowing for hands-on activities in troubleshooting of industrial pneumatic applications. This system gives access to various electrical and pneumatic components which are connected to create six unique applications. The operator control section allows for direct manual and automatic control of each application. Lastly the system includes fault insertion capability to assist in development of a systematic approach to troubleshooting.

The Pneumatic Troubleshooting Training System is the most capable and comprehensive pneumatics training aid of its kind. Complete with Pick & Place, Loading Actuator, Rotary Manipulator, Free Wheeling Motor/Brake, Air Over Oil, and Operator Control Station.

-

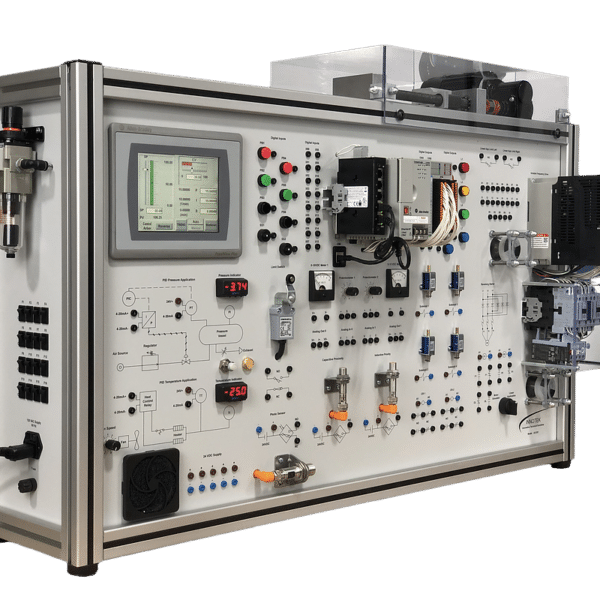

PLC Automation Training System | all-in-one

The ATS-200 Automation Training System provides students with a hardware platform for performing hands-on skills development activities for automation technologies operations. The tabletop or mobile platform includes various applications which can be quickly connected to provide advanced activities, expanding the learning objectives beyond simple on/off functionality.

The all-in-one PLC Training System includes:

◉ Operator Control Application

◉ Sensors and Switches Application

◉ Pneumatic Actuator/Valve Application

◉ Linear Ball Screw Application

◉ BCD Thumbwheel and 7 Segment Display

◉ Dual Analog Potentiometer and Meters

◉ Motor Control Application

◉ Variable Speed Drive (Any Brand)

◉ PLC (Any Brand)

◉ HMI (Any Brand)

◉ PID Pressure Application

◉ PID Temperature Application

The system shown as tabletop trainer with banana jack connections. The unit can be purchased with a mobile frame with all components pre-wired to the PLC requiring no additional connections.

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.

-

Tabletop Wiring Training System

The compact, tabletop EW-101 Electrical Wiring Training System allows for hands-on student lab activities in wiring residential, commercial/industrial, HVAC, and low-voltage systems (fire alarm, security system, etc) circuits.

The double-sided, hands-on training system gives students safe and approachable access to wire various circuits and devices commonly found in real world settings.

Customize your system by choosing your training focus (two per training system):

-

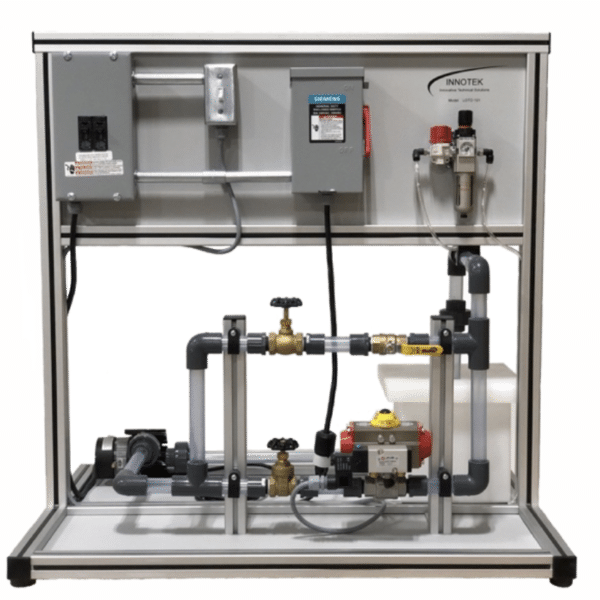

Lock-Out Tag-Out Training System

The Innotek Lockout-Tagout Training system provides learners with hardware allowing for demonstration and assessment of LOTO procedures. Lock-Out Tag-Out trainer puts students in the front seat of proper safety procedures in industrial workplaces.

According to the Occupational Safety and Health Administration (OSHA), lock-out/tag-out is one of the Top 10 “”Most Serious Violations”” and “”Most Often Cited Violations”” in industrial workplaces. LOTO must be taken seriously, as lives could be at stake. Workers maintaining equipment can be seriously injured from the unexpected energization of, release of stored energy from, or startup of equipment.

Proper Lock-Out Tag-Out procedures establish standards for the shutdown of equipment, so that energy sources can be isolated to prevent the release of potentially-hazardous energy during routine maintenance activities. Following proper LOTO procedures helps workers to avoid preventable workplace accidents and injuries.

The LOTO-101 training system is a functional system and operates a pump/tank circuit with various power sources and valves for multiple training scenarios. All required safety devices are included with the system for both electrical and mechanical devices.