Description

Overview

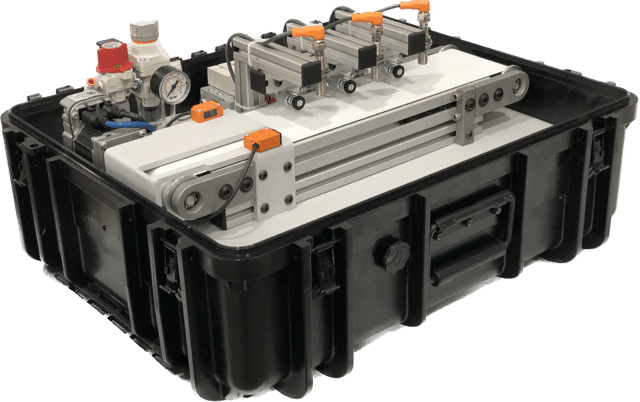

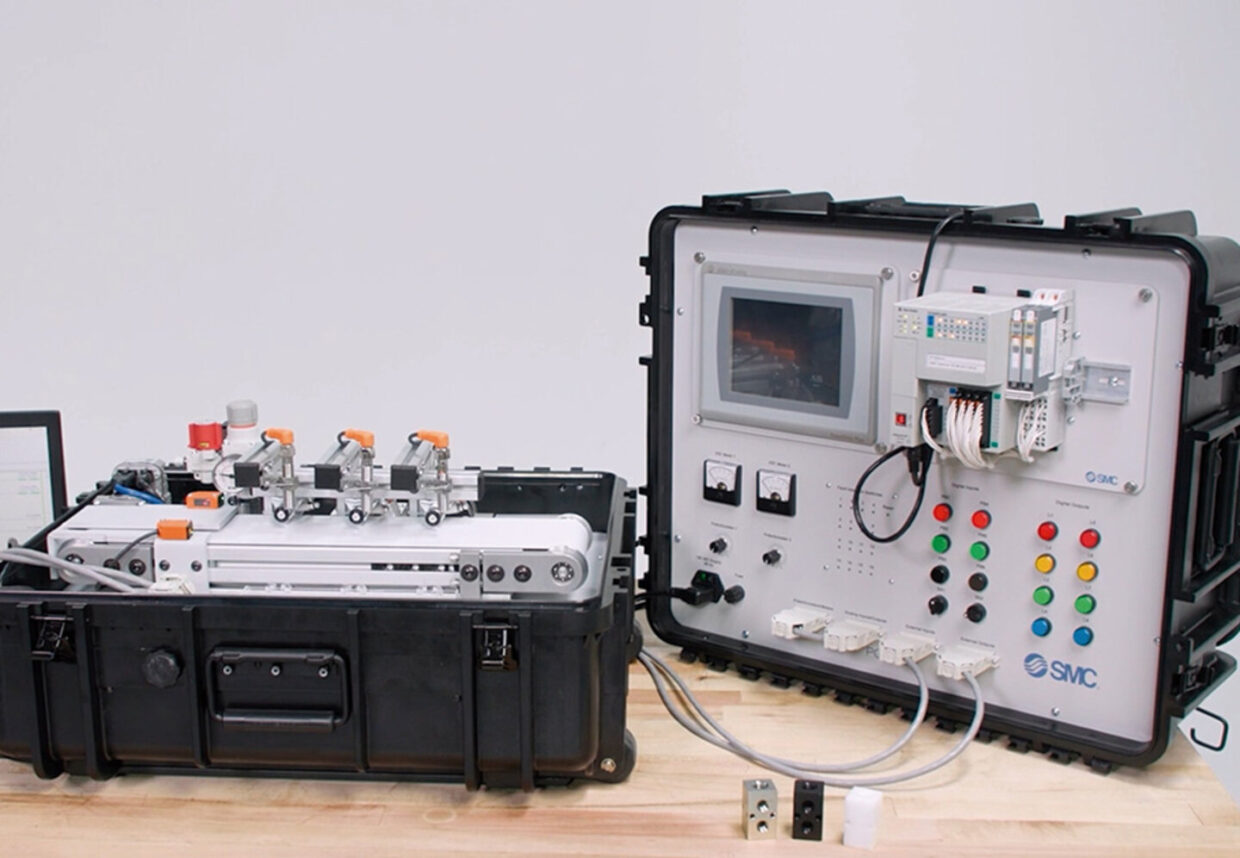

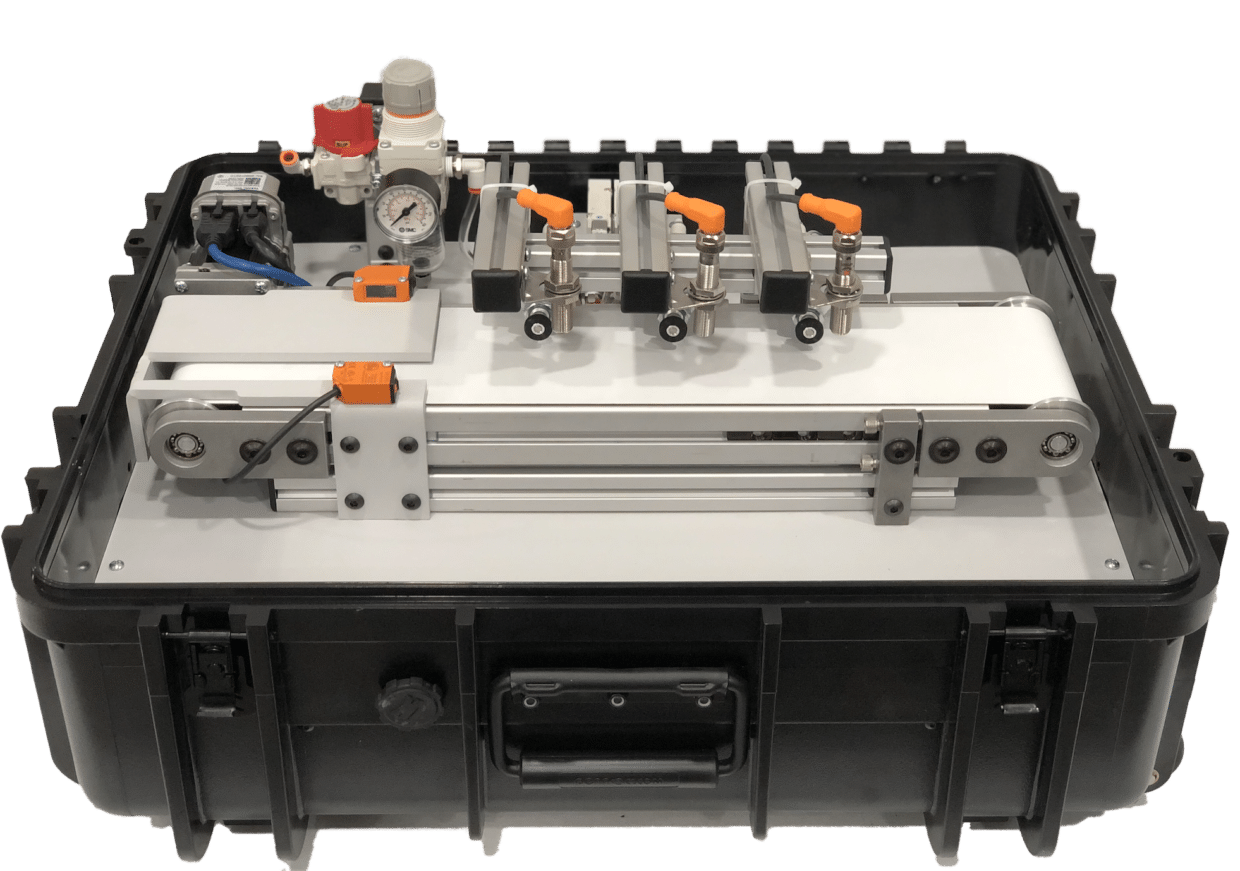

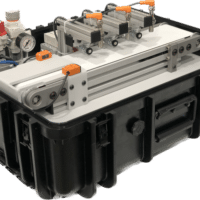

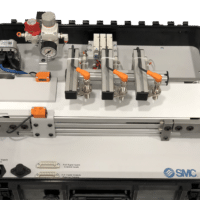

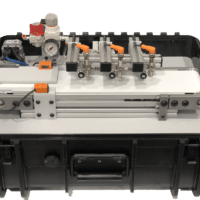

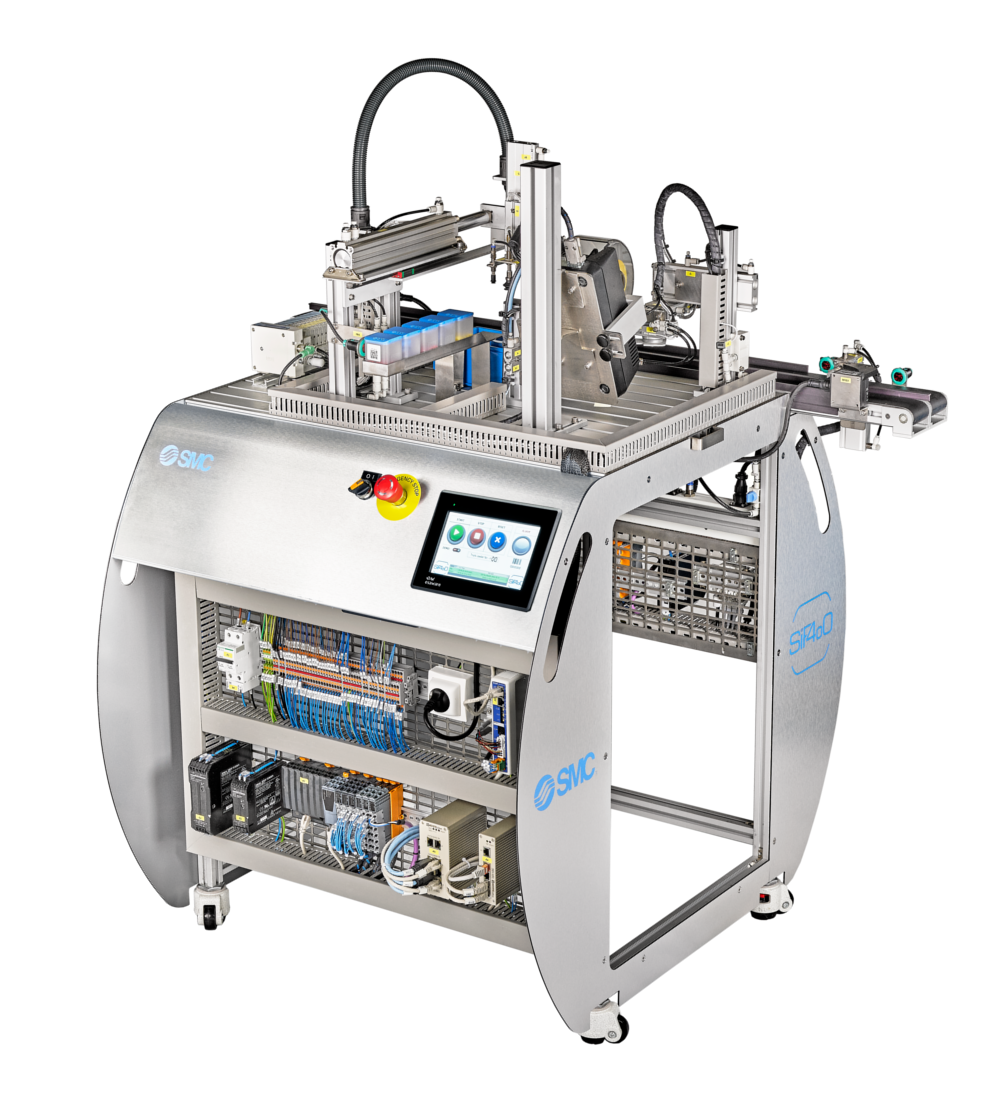

The Suitcase Conveyor Trainer is a compact, portable conveyor belt simulation unit engineered for hands-on training in automation, mechatronics, and industrial sensor systems. Designed to fold into a rugged carrying case, this system delivers realistic object classification and conveyor control scenarios—ideal for classrooms, labs, and field instruction.

Whether you’re teaching smart factory workflows, object detection with sensors, or conveyor belt mechanics, this trainer simulates real industrial conditions in a safe, accessible format.

Application: Real-Time Object Classification Using Sensors

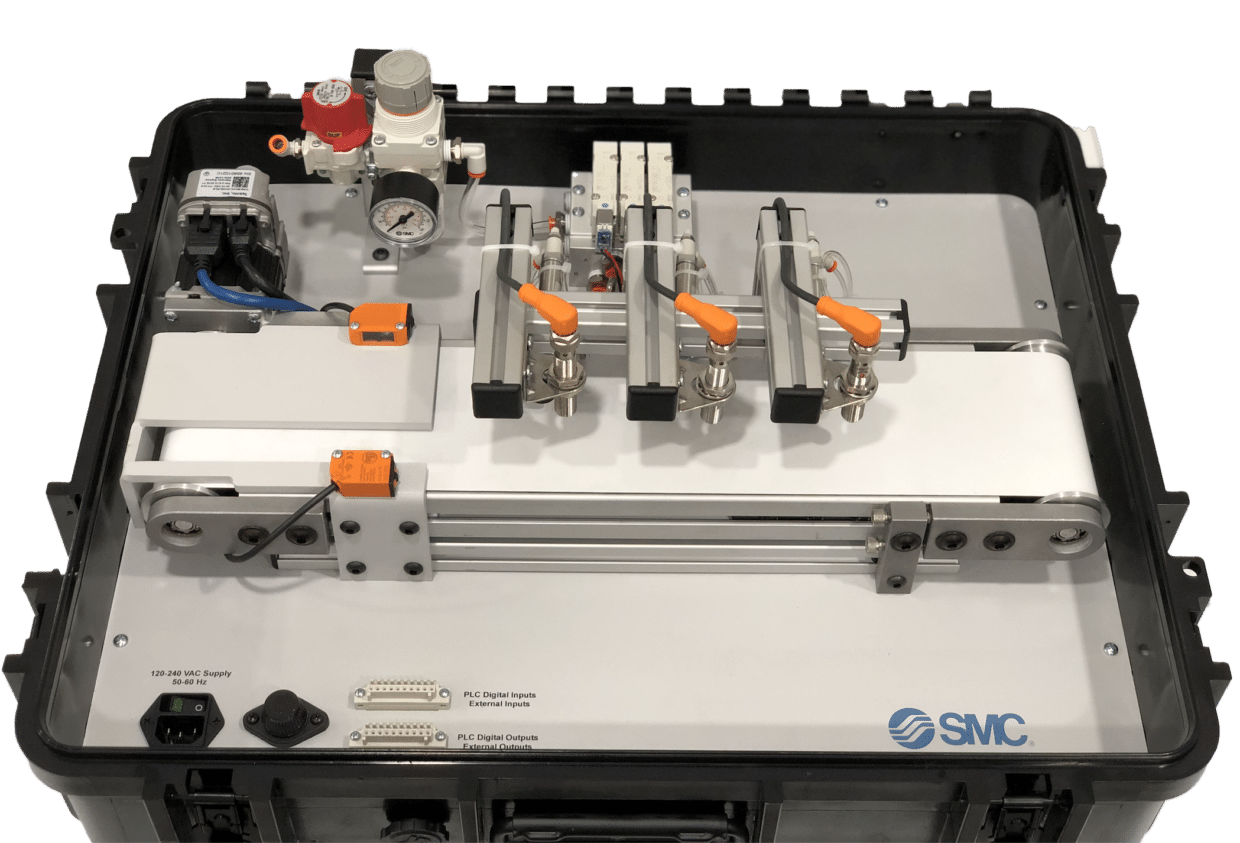

The system can be configured to simulate automated object classification using a combination of:

-

Photoelectric and proximity sensors

-

Inductive and capacitive detectors

-

Color and shape sensors (optional add-ons)

-

Programmable sorting logic via PLC or microcontroller interface

As objects move along the conveyor, trainees learn to:

-

Adjust sensor positioning and sensitivity

-

Interpret sensor signals

-

Configure basic logic rules to classify or reject items

-

Trigger actuators (e.g., diverters or stop gates) based on object characteristics

This makes it a powerful tool for simulating smart material handling, quality control processes, and automated inspection lines—without the cost and complexity of a full-scale setup.

Key Features

-

Industrial Conveyor Simulation: Working belt system with drive motor, rollers, tensioners, and sensor mounts.

-

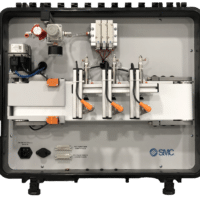

Plug-and-Play Setup: No external control cabinets needed—just connect and begin.

-

Modular Sensor Integration: Compatible with analog and digital sensor types.

-

Safe for Classrooms: Fully enclosed electrical system with emergency stop.

-

Built to Travel: Compact suitcase-style frame with foam-protected inner lining.

Technical Specifications

| Feature | Details |

|---|---|

| Motor | AC Induction, 115V |

| Belt Speed Control | Variable with manual knob |

| Sensor Mounts | Adjustable, supports standard industrial sensors |

| PLC Interface | 24VDC I/O compatible terminal strip |

| Dimensions (Closed Unit) | 24″ x 20″ x 12″ |

| Total Weight | 50 lbs |

Learning Outcomes

Students and trainees will gain experience in:

-

Sensor wiring and calibration

-

Object recognition using proximity, color, and photoelectric sensors

-

Conveyor belt tracking and adjustment

-

Programming logic for classification and sorting

-

System troubleshooting and diagnostics

Ideal for mechatronics, industrial maintenance, electrical technology, and STEM programs.

Ideal For

-

Technical & Vocational Schools

-

Industrial Training Programs

-

Maintenance Technician Training

-

Engineering Lab Simulations

-

Smart Factory and Industry 4.0 Demonstrations