Description

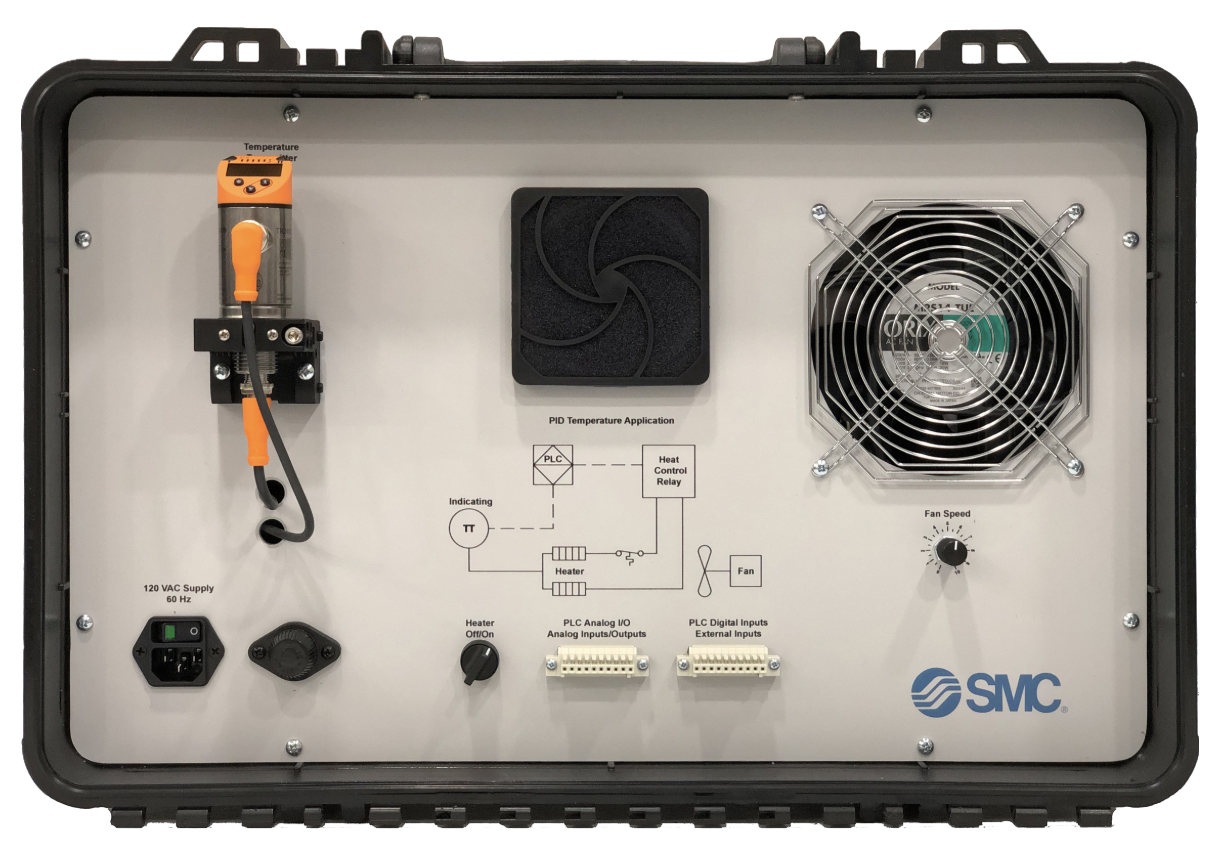

PLC Training Application – PID Temperature Control Application

Portable PID Temperature Simulation for Hands-On PLC Learning

SMC’s PID Temperature Control Application is a compact, suitcase-based training unit that teaches the principles of closed-loop temperature regulation using PLC-based PID control. It allows learners to observe, tune, and optimize heating cycles using live sensor data, PLC outputs, and real-time process response.

By bridging classroom theory with industrial realism, this application helps students and professionals gain confidence programming PID loops for thermal systems using Toolkit’s PLC Trainers or industry-standard controllers such as Siemens, Allen-Bradley, and Mitsubishi.

Key Features

Real-Time PID Temperature Regulation

-

Simulates a real-world heating process

-

Controlled via PLC analog output to a heating element

-

Feedback from a precision temperature sensor (temperature transmitter)

Practical PID Tuning Experience

-

Program P, I, and D values via the PLC

-

Monitor temperature rise, overshoot, and stability

-

Includes job sheets for typical tuning scenarios (Ziegler-Nichols, trial-and-error)

Easy PLC Integration

-

Connects to Toolkit PLC Trainers or other brands

-

Analog input/output terminals for sensor and actuator wiring

-

Includes reference ladder logic examples and student worksheets

Portable & Classroom-Ready Design

-

Packaged in a rugged SmartCase™ for protection and portability

-

Built-in safety features: thermal cutoff, visual indicators

-

Clear wiring layout for instructional use

What’s Included

-

SMC PID Temperature Control Unit

-

Heating Element (Low Voltage)

-

RTD or Thermistor Sensor

-

Pre-wired Analog I/O Connectors

-

Real-Time Temperature Display or Gauge

-

24V Power Supply

-

PID Tuning Worksheets & Instructor Guide (Digital PDF)

Who This Is For

-

Technical Schools & University Engineering Programs

-

Industrial Controls & HVAC Training Centers

-

Automation Technician Bootcamps

-

STEM & Mechatronics Labs