Mechatronics

Mechatronics is the big-strange word that covers so much. The marriage of mechanical, electrical, computer and software skills in order to work with smart technologies, TOOLKIT prepares students for various career pathways within the ever-changing landscape of Mechatronics.

Students learn integrated systems that combine electrical technologies with mechanical technologies and computer programming for real-world skills that directly relate to modern jobs in manufacturing and automation.

Mechatronics sits at the intersection of mechanics, electronics, and computing, and is built on the idea of creating simpler and smarter systems. Toolkit provides the training systems that empower mechatronics technicians and specialists with the skill sets to thrive in contemporary, advanced automated manufacturing industries.

Electro-mechanical technologists and technicians combine knowledge of mechanical technology with knowledge of electrical and electronic circuitry. They operate, test, and maintain unmanned, automated, robotic, and/or electromechanical equipment.

Electro-mechanical and mechatronics technologists and technicians typically do the following:

- Read blueprints, schematics, and diagrams to determine the method and sequence of assembly of a machine or a piece of equipment

- Verify dimensions of parts, using precision measuring instruments

- Operate metalworking machines to make housings, fittings, and fixtures

- Inspect parts for surface defects

- Repair and calibrate hydraulic and pneumatic assemblies

- Use instruments to test the performance of electromechanical assemblies

- Use soldering equipment and hand tools to install electronic parts and hardware

- Operate, test, or maintain robotic equipment

- Analyze and record test results

They install, maintain, and repair automated machinery and computer-controlled mechanical systems in industrial settings, and also test, operate, and/or maintain robotic equipment at worksites. This equipment may include unmanned submarines, aircraft, or similar types of equipment for uses that include oil drilling, deep-ocean exploration, or hazardous-waste removal.

They average pay for someone with these skills is over $61,040.00.

Showing all 5 results

-

SMC Flexible Manufacturing System – Industry 4.0

The best just got better with this incredible training from SMC! SMC’s FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market for mechatronics and industrial troubleshooting training and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training.

The SMC Flexible Manufacturing System is used by countless companies and schools across the globe for real industry training.

-

SMC Flexible Assembly System FAS-200

SMC’s FAS-200 Flexible Assembly System is a tried-and-true industrial training system for automation, advanced manufacturing, industrial maintenance, and industrial technology students. Featuring all industrial components and technologies from industry leading manufacturers, the FAS-200 exposes students to industry’s most common technologies with hands-on skills development in pneumatics, hydraulics, PLCs, robotics, troubleshooting, and more!

Customize your modular training system with your choice of Stations, PLCs, Robots, and More!

-

Highly Automated Training System HAS-200

Train your students with the same Industry 4.0 training system used by companies like Intel and Boeing for their workforce training!

The HAS-200 SE i4o brings SMC’s industry leading technologies into a modular, customizable smart factory for education with training options in PLC programming, HMI programming, Management Execution Systems software, interconnected systems, smart devices, robotics, and more.

-

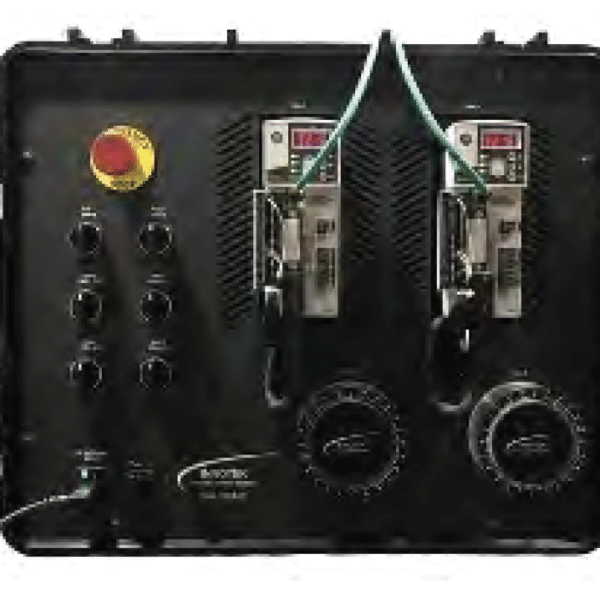

Servo (Drives) Motion Training System

The Servo Motion Training System provides participants with hardware allowing for hands-on experiments in setup,

configuration and programming and servo drives for rotary or linear motion. The system gives access to onboard input and

output devices in addition to providing connectivity for external devices.

The system can be purchased with a Motion-Capable PLC or utilized in combination with an existing motion-capable PLC.

Tabletop or Suitcase Form Factor

- 120Vac Power Entry

- Emergency Stop

- (3) Selector Switches (Enable, + Over-Travel, – Over-Travel)

- (2) Homing Sensors

- (2) Servo Rotary Axis

- (2) Servo Drives

-

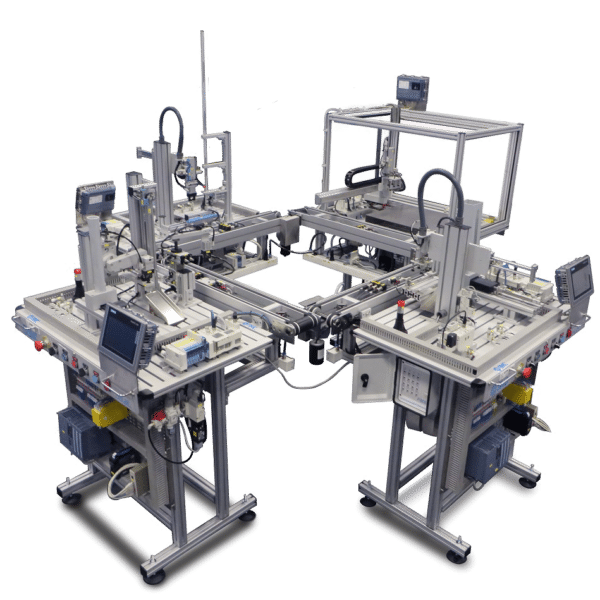

4-Station Flexible Manufacturing System i4o

The best just got better with this incredible training from SMC! The FMS-200 Special Edition Industry 4.0 takes the most popular industrial advanced mechatronics training system on the market and combines it with advanced Industry 4.0 technologies for real-world, skills-driven training for industry.

The 4-Station Configuration brings classrooms a compact and expandable solution for hands-on Industry 4.0 training with built-in troubleshooting.

Students will get industry-relevant hands-on training around the crucial skills demanded by manufacturing and industry. Industrial manufacturing skills student expect to receive include automation processes, safety, PLC programming, Distributed IO, smart devices, artificial vision, and more!