Industry 4.0

With so much noise around Industry 4.0 and contradicting definitions from one person to the next, it’s no surprise to see why so many schools and teachers don’t know where to begin in training students in the classroom. Toolkit is proud to be the undisputed leader in providing schools and industry professionals Industry 4.0 Training Solutions.

How does one identify the important topics and skills to cover in the classroom when there are so many areas and directions one could take?

Toolkit is here to help with this. Lean on us as you prepare your students for the 4th Industrial Revolution, and we will guide you with the industry’s most intuitive and most robust portfolio of Industry 4.0 training solutions on the market.

From smart devices, IO-link, collaborative and industrial robots, networking and communication protocols, mobile robots, Management Execution Softwares, Predictive Maintenance, Cybersecurity, Data Analytics and more – training for a rapidly digitalizing and changing manufacturing world can be a daunting challenge.

History of i4o

The Fourth Industrial Revolution (Industry 4.0) is a term for the current state of digital expansion seen across the globe and within every industry. It’s a new era that builds on and extends the impact of digitization in new and unanticipated ways. Industry 4.0 has been made possible by digitizing and automating the computerization of previous industrial revolutions through autonomous, cyber-physical systems and machine learning. Rapid disruptive advances in technology like artificial intelligence, robotics, blockchain, and 3D printing have created uncertainty and fear of increased unemployment and inequality.

Recent studies from McKinsey estimate that nearly 375 million workers may need to switch occupational categories as a result of the Industry 4.0. For advanced economies, up to one-third of the 2030 workforce in the United States and Germany, and nearly half in Japan may need to learn new skills and find other occupations. Jobs are not as cut and dry as they once were; most occupations require a set of varied skills and tasks. But rather than being replaced by robots, many jobs will see an increase in the amount of tasks which can be automated.

In fact, McKinsey found that less than 5% of global occupations can be replaced by automation. However, in about 60% of occupations, about a third of associated tasks could be automated, causing workers to either find new jobs or upgrade skills to meet demands.

Automation and Jobs

The low-skilled, repetitive jobs that are at highest risk for replacement through automation will also require new high-skilled positions focused on management, quality control, and require increased supervision. Cost savings in production could, in theory, be translated to reduced product price and thus increased demand, actually helping the economy. Which could potentially increase demand for partly automated occupations.

Toolkit prides itself on providing learners with the Industry 4.0 cyber physical training systems and certifications to prepare the next generation of the workforce.

Showing all 9 results

-

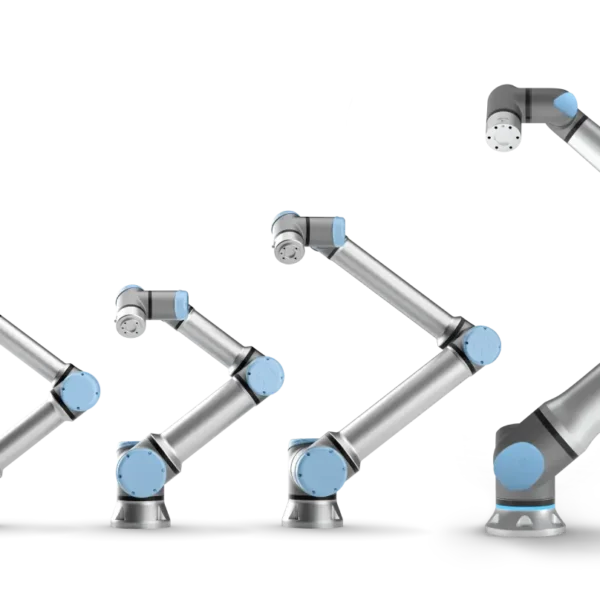

Universal Robots Collaborative Robots

Toolkit Technologies is proud to offer Universal Robots’ industry-leading collaborative robots to education and training institutions around the country.

Empower your students with cutting-edge industrial skills training solutions using Universal Robots’ collaborative robots. Our hands-on training systems, featuring all-industrial technologies sourced from industry leaders like SMC, UR, Miller Electric, and others, immerse learners in real-world applications that prepare them for dynamic careers in today’s tech-driven workforce.

Elevate your educational programs with our state-of-the-art robotics technology, fostering innovation and expertise in your students. Explore our range of training solutions now for comprehensive technical education solutions that drive future success.

We are proud to offer robust curriculum, eLearning, on-site training, and custom training applications with every UR Robot.

Let us know what robotics application you want to teach, and we’ll build it!

-

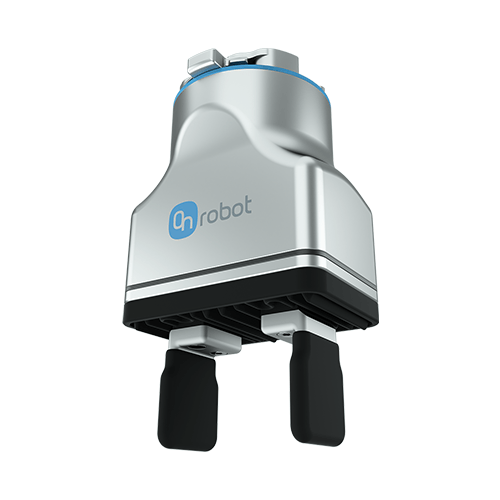

OnRobot RG2 Robot Gripper

ASK FOR EDU DISCOUNTS!

The OnRobot RG2 – 2kg payload robot arm gripper is a flexible, collaborative gripper with built-in Quick Changer and is the perfect 2-Finger Adaptive Robot Gripper for your robot needs.

With OnRobot, swapping in- and- out grippers is as easy as the push of a button! Quick-Change Grippers for all of your robot gripper needs!

-

OnRobot RG6 Robot Gripper

ASK FOR EDU DISCOUNTS!

The OnRobot RG6 – 6kg payload robot arm gripper is a flexible, collaborative gripper with built-in Quick Changer and is the perfect 2-Finger Adaptive Robot Gripper for your robot needs.

With OnRobot, swapping in- and- out grippers is as easy as the push of a button! Quick-Change Grippers for all of your robot gripper needs!

-

OnRobot 2FG7 Parallel Gripper

ASK FOR EDU DISCOUNTS!

OnRobot’s 2FG7 is the tried-and-true, complete, low-cost, off-the-shelf electric parallel gripper that can be deployed within minutes and requires no custom engineering for installation, programming, or maintenance. The 2FG7 is easily redeployed on any major collaborative or light industrial robot, making it ideal for low-volume, high-mix production, and enabling fast ROI for many different applications.

Like all OnRobot grippers, the 3FG15 offers seamless integration with the robots of your choice, and is quickly swappable with the press of a button.

-

OnRobot 3FG15 3-Finger Gripper

ASK FOR EDU DISCOUNTS!

OnRobot’s 3FG15 3-Finger Gripper is ideal for gripping a wide range of cylindrical objects in machine-tending applications such as CNC lathe machines. The gripper’s design automatically centers workpieces, resulting in fast deployment with a strong, stable grip and precise placement. With a payload of up to 15kg, the 3FG15 competes with larger, bulkier, and much less flexible finger grippers.

Like all OnRobot grippers, the 3FG15 offers seamless integration with the robots of your choice, and is quickly swappable with the press of a button.

-

OnRobot VGC10 Electric Vacuum Gripper

ASK FOR EDU DISCOUNTS!

The OnRobot VGC10 is the COMPACT, versatile electric vacuum gripper for all different types of robotic pick & place applications! Adjust the fingers, footprint, and suction independently.

With OnRobot, swapping in- and- out grippers is as easy as the push of a button! Quick-Change Grippers for all of your robot gripper needs!

-

OnRobot VG10 Electric Vacuum Gripper

ASK FOR EDU DISCOUNTS!

The OnRobot VG10 is the versatile electric vacuum gripper for all different types of robotic pick & place applications! Adjust the fingers, footprint, and suction independently.

With OnRobot, swapping in- and- out grippers is as easy as the push of a button! Quick-Change Grippers for all of your robot gripper needs!

-

OnRobot Eyes (Robot Vision)

ASK FOR EDU DISCOUNTS!

OnRobot’s Eyes, a robot camera solution, makes it easy and affordable to deploy vision for almost any collaborative application. Eyes is ideal for sorting a variety of objects, CNC machine tending with metal parts that are defined by outer shape, and many other pick-and-place applications where orientation is important.

-

OnRobot Screwdriver (Automated Robotic Assembly)

ASK FOR EDU DISCOUNTS!

You can easily automate assembly processes with the new intelligent OnRobot Screwdriver for light industrial and collaborative robots. Intelligent error detection and multiple screw size handling will ensure consistent results while helping you assemble the product of your desires!