Description

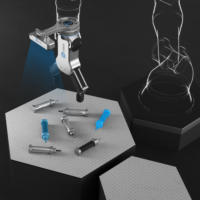

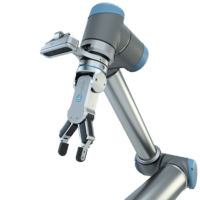

With the OnRobot Eyes you can now easily sort, pick and place unstructured applications with high reliability using any robot arm. Eyes can be mounted on the robot wrist or externally, with position adjustments to adapt to your application, and integrates seamlessly with the robot interface and gripper through the OnRobot Quick Changer. Deployment is fast, so there is minimal downtime for changeovers to new products or processes. One-picture calibration and part recognition takes just minutes, and programming is intuitive and fast. And with Eyes’ advanced, affordable 2.5D vision, you get depth perception and the ability to stack parts, without adding complexity.

Easy One System setup for any leading robot brand with software that is easy to install and program, so even employees with no technical background can set it up.

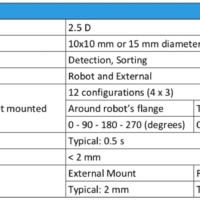

The Eyes can be mounted on the robot arm or externally. There are multiple reconfigurations available – around the robot flange and tilt orientation.

Simply take a picture of the work surface to calibrate camera view, and a picture for each workpiece the system should detect.

Depth perception used for application such as stacking or handling items of various heights

- Quickly and easily add vision to robotic applications with one-picture calibration, fast programming and seamless gripper integration

- Affordable, efficient 2.5D vision offers depth perception for varying heights or stacked objects

- Flexible, adaptable vision system with on-robot or external mounting is ideal for almost any collaborative application

- Easily sort, pick and place unstructured applications with high reliability using any robot arm

- One-shot detection for multiple objects minimizes cycle time

- Inspect objects using color and contour detection—with or without a robot, and ensure consistent quality

- Automatic landmark enables dynamic working environments and mobile robot setups