Ag Mechanics

Toolkit is proud to offer the very best Ag Mechanics Training Systems for schools and workforce development programs.

The heartbeat of America’s farmland, nothing would be possible in modern agriculture practices with machinery and technicians who know how to operate, fix, repair, and maintain this machinery.

Ag Mechanics Job Outlook

Ag Mechanics refers to the people and technology that helps farmers and ranchers maintain their lands – from building or troubleshooting hydraulic circuits to welding or diagnosing/repairing a diesel engine.

Known as Agricultural Equipment Mechanic, Combine Mechanic, Dairy Equipment Mechanic, Dairy Equipment Repairer, Harvester Mechanic, Irrigation Equipment Mechanic, Milking Machine Mechanic, or Tractor Mechanic.

The overall job outlook for Farm Equipment Mechanic or Service Technician careers has been positive since 2004. Vacancies for this career have increased by 16.09 percent nationwide in that time, with an average growth of 1.01 percent per year. Demand for Farm Equipment Mechanics and Service Technicians is expected to go up, with an expected 5,580 new jobs filled by 2029. This represents an annual increase of 1.74 percent over the next few years

Toolkit is here to bring hands-on and exciting Ag Mechanics Training Systems to CTE classrooms.

Showing 1–12 of 20 results

-

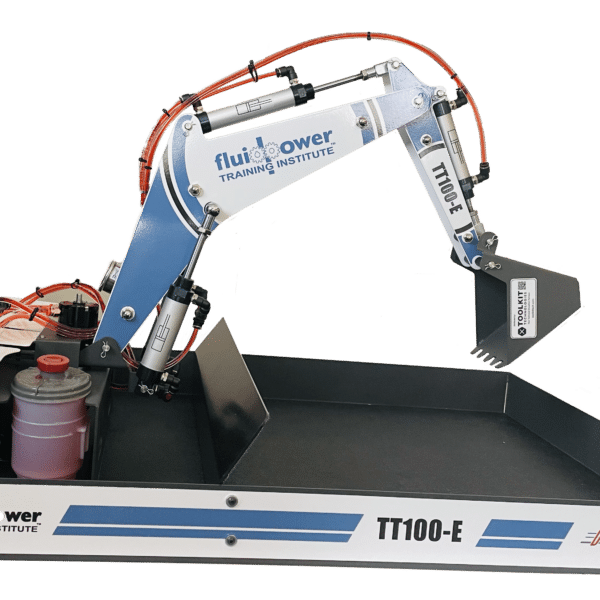

Tabletop Hydraulic Excavator Kit

Our brand new tabletop hydraulics excavator kit brings real-world hydraulic principles to life for students to explore hydraulics in an engaging and project-based approach!

Build your excavator and learn the basic hydraulic concepts necessary for industrial skills in agriculture, industrial maintenance, heavy truck, and manufacturing careers.

Build, Create, Dig, and Learn!

-

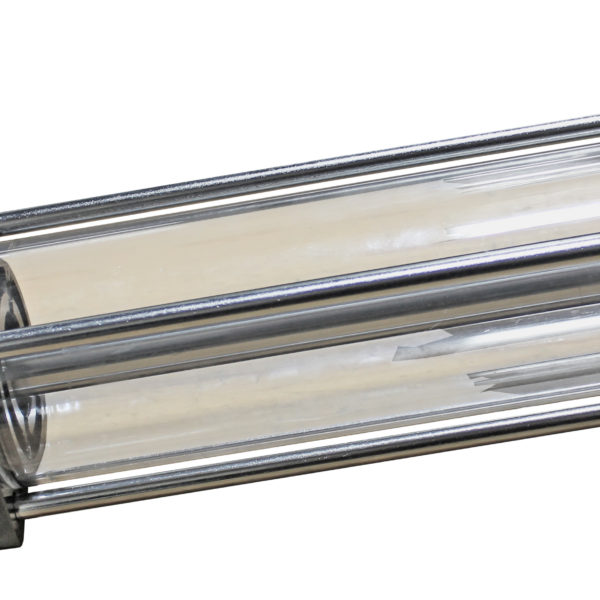

Cutaway Hydraulic Cylinder

Enhance hands-on hydraulics training with our clear acrylic cutaway hydraulic cylinder. Designed for educational environments, this fully functional, double-acting, single-rod cylinder features a transparent body that reveals the internal piston, rod, seals, and flow paths in real time. Ideal for teaching hydraulic flow and pressure intensification, seal function, and component interaction, it includes breathable ports for smooth rod movement and visual learning. Perfect for technical training labs and fluid power courses.

-

FPTI Hydraulics Training System MF-102-H

Upgrade your hydraulics training with the Fluid Power Training Institute’s MF-102-H Hydraulic Training System by Toolkit Technologies. This USA-made, industrial-grade system delivers over 40 hours of hands-on learning in hydraulics, safety, schematics, and advanced concepts. Perfect for technical classrooms, it features robust components, flexible configurations, and optional modules to expand capabilities. With expertly designed educational materials and real-world applications, the MF-102-H is the ultimate solution for teaching foundational and advanced hydraulics. Discover unmatched quality and performance with this industry-leading training system today!

The hydraulics trainer comes in either single- or double-sided configurations and comes complete with instructional materials for teaching industrial hydraulics.

-

FPTI Hydraulics Training System with Troubleshooting MF-102-H-TSE

Our Fluid Power Training Institute FPTI MF-102-H-TSE Hydraulic Training System with Troubleshooting and Electronic Fault Insertion takes hydraulics training to a whole new level.

This USA-made, industrial-grade system delivers over 40 hours of hands-on learning in hydraulics, safety, schematics, and advanced concepts. Perfect for technical classrooms, it features robust components, flexible configurations, and optional modules to expand capabilities. With expertly designed educational materials and real-world applications, the MF-102-H-TSE is the ultimate solution for teaching foundational and advanced hydraulics as well as troubleshooting. Discover unmatched quality and performance with this industry-leading training system today!

The MF-102-H-TSE includes Electronic auto-fault insertion through a built-in PC panel with 22” touch-screen makes, which makes it possible for almost every component on the hydraulics training system to automatically “wear out.” The MF-102-H-TSE hydraulics training system with troubleshooting emulates real-world wear patterns in hydraulic components for students to gain real-world skills.

The hydraulics trainer comes in either single- or double-sided configurations and comes complete with instructional materials for teaching industrial hydraulics.

-

Load-sensing Mobile Directional Control Valve Cutaway

Cutaway Load-Sensing Mobile Directional Control Valve – MDCV-LS-CM

Turn complex hydraulics into clear, visual learning with this advanced load-sensing mobile directional control valve trainer. Featuring a dissected valve body and a transparent-mounted shuttle valve, this fully functional model visually demonstrates how a single load-sense line monitors pressure in both A and B ports. Ideal for teaching mobile hydraulic systems, pump communication, and load-sense behavior, it’s the perfect training tool for simplifying system diagnostics and student understanding.

-

Mobile Directional Control Valve Cutaway Model

Cutaway Mobile Directional Control Valve – Fully Functional Sectional Valve Trainer

Bring hydraulic concepts to life with this sectional mobile directional control valve, precision-cut to reveal all seven internal valve functions. Students can interact with the moveable spool using the included control lever and explore integrated anti-cavitation valves, cylinder port reliefs, and load check valves. This hands-on training tool offers unmatched visibility and clarity, transforming complex valve systems into tangible, easy-to-understand mechanics.

-

Over-Center, Variable Displacement Pump Cutaway

Cutaway Over-Center Axial Piston Pump – Hydrostatic Training Model

This handcrafted axial piston pump cutaway is the ultimate hands-on teaching tool for hydrostatic drive systems. Featuring over-center swashplate movement, a cutaway barrel to the drive shaft, dual main pressure relief valves, and a transparent rear-mounted gerotor charge pump, it offers unmatched visibility into internal pump dynamics. Students can manually operate the swashplate and rotate the input shaft to see how reversing flow is achieved without changing shaft direction—bringing advanced fluid power concepts vividly to life.

-

Two-Stage Directional Control Valve Cutaway

Cutaway Two-Stage Hydraulic Directional Control Valve – Sizes 03 & 08

Demystify advanced hydraulics with this handcrafted, cutaway two-stage directional control valve—featuring fully functional solenoid-controlled, pilot-operated spools. Designed for fluid power training, the internal and external drain paths and sub-plate mount are clearly visible. Every internal oil passage is exposed, revealing how the pilot valve actuates the main valve. This interactive model transforms complex hydraulic concepts into instant “aha” moments for students.

-

MF102 Hydraulics Trainer + Troubleshooting

We are proud to bring this incredible hydraulics training system to schools whereby students can get invaluable hands-on training in the fundamentals of Hydraulics, Hydraulics Safety, Advanced Hydraulics, and now the added training benefit of Troubleshooting capabilities.

The MF102-H-TS includes 40-hours of possible training on the base model PLUS an additional 40-hours of training in troubleshooting possible. Unparalleled in terms of craftsmanship and curriculum, this trainer is proudly designed and built in the USA.

Available Single-Sided or Double-Sided

-

MF102 Hydraulics Trainer with Troubleshooting and Touchscreen

The best hydraulics training system on the market keeps getting better! Fluid Power Training Institute’s MF102-H-TSE Hydraulics Training System with Troubleshooting now includes a built-in Touchscreen Monitor and PC for practical lab activities, troubleshooting, and student tracking!

Students get in-depth, hands-on training in the fundamentals of hydraulics, advanced hydraulics, troubleshooting, safety, and more with over 40 hours of curriculum in the base system, additional 40 hours in troubleshooting, and more with additional options.

With the built-in monitor, instructors can automatically track student activity to determine whether they truly understand how to effectively diagnose hydraulics problems or are just “replacing parts” at random!

Available in single-sided or double-sided systems.

-

Hydrostatic Transmission + Driving Simulator

The MF500-HT-TSE is an instructor’s “dream-come-true” with respect to teaching state-of-the-art, electronically-controlled hydrostatic transmission systems – hands-on. It can even be driven as if it were on a construction site, in real-time!

Driving a skid-steer loader around a construction site and operating the MF500-HT-TSE in the lab amounts to the same thing – without the hazards!

Designed for instructors who want to teach hydrostatic transmission and steering systems with the same components found in popular front-end loaders but without the safety hazards and physical limitations of operating a loaded, faulty skidsteer in a shop full of students.

Teach basic concepts to advanced applications + troubleshooting in a classroom-friendly manner where students can gather around to see real-time symptoms of faults as you drive the simulator through a variety of scenarios.

-

Pump Cavitation Trainer

The FP-MF200-CAV simulator is the most advanced trainer in the world for teaching students everything they need to know about cavitation, its common causes, and its devastating effect on a hydraulic system.

Much thought went into the design of this training masterpiece. The transparent reservoir, transparent pump suction line, and transparent pump outlet port transmission line are backlit to enhance the stunning visual impact this simulator offers.

Students learn:

- How the inlet side of a hydraulic pump works

- Why it is critical to establish a “trend” for pump inlet restriction

- How and why cavitation occurs

- Safe and effective diagnostic procedures for determining the root-cause of cavitation