Manufacturing

Showing 13–22 of 22 results

-

Tabletop Wiring Training System

The compact, tabletop EW-101 Electrical Wiring Training System allows for hands-on student lab activities in wiring residential, commercial/industrial, HVAC, and low-voltage systems (fire alarm, security system, etc) circuits.

The double-sided, hands-on training system gives students safe and approachable access to wire various circuits and devices commonly found in real world settings.

Customize your system by choosing your training focus (two per training system):

-

Lock-Out Tag-Out Training System

The Innotek Lockout-Tagout Training system provides learners with hardware allowing for demonstration and assessment of LOTO procedures. Lock-Out Tag-Out trainer puts students in the front seat of proper safety procedures in industrial workplaces.

According to the Occupational Safety and Health Administration (OSHA), lock-out/tag-out is one of the Top 10 “”Most Serious Violations”” and “”Most Often Cited Violations”” in industrial workplaces. LOTO must be taken seriously, as lives could be at stake. Workers maintaining equipment can be seriously injured from the unexpected energization of, release of stored energy from, or startup of equipment.

Proper Lock-Out Tag-Out procedures establish standards for the shutdown of equipment, so that energy sources can be isolated to prevent the release of potentially-hazardous energy during routine maintenance activities. Following proper LOTO procedures helps workers to avoid preventable workplace accidents and injuries.

The LOTO-101 training system is a functional system and operates a pump/tank circuit with various power sources and valves for multiple training scenarios. All required safety devices are included with the system for both electrical and mechanical devices.

-

Transformer Training System

We are proud to offer 2 different models of the Transformer Training System:

TRX-101: Fundamental Transformer Training System

TRX-201: Transformer Training System

Both Transformer Training System models provide participants with the necessary hardware for students to learn through hands-on experiments in transformer connections and operation.

-

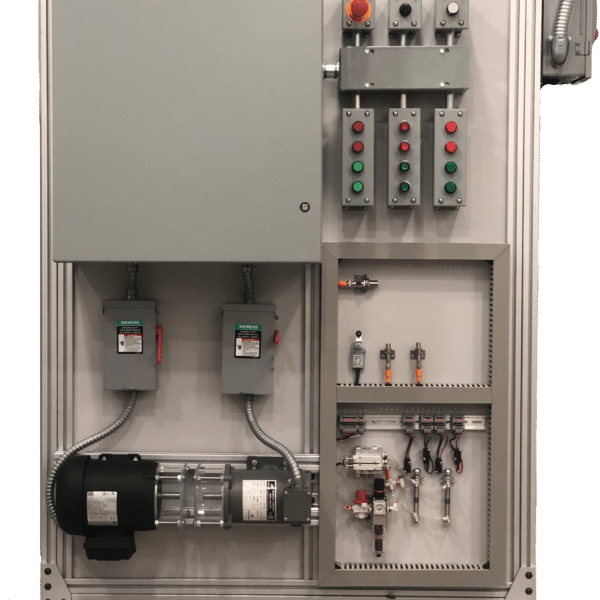

Industrial Wiring Training System

The IW-201 Industrial Wiring Training System is a complete hands-on training solution for teaching the concepts of residential, commercial and industrial wiring in a compact and mobile classroom setting.

The Innotek Industrial Wiring Training System IW-201 allows students to study and practice electrical wiring skills like conduit bending, installing and wiring motor controls in a NEMA Electrical panel, terminating wires and choosing correct wire size, installing wiring into devices, and more!

The skills-based approach of the IW-200 is an invaluable tool for students studying/training to be electricians, industrial maintenance technicians, and/or advanced manufacturing operators, as it builds confidence through hands-on activities and competency-based exercises.

- Power Distribution, Wiring, and Devices

- Conduits and Enclosures

- Industrial Controls

-

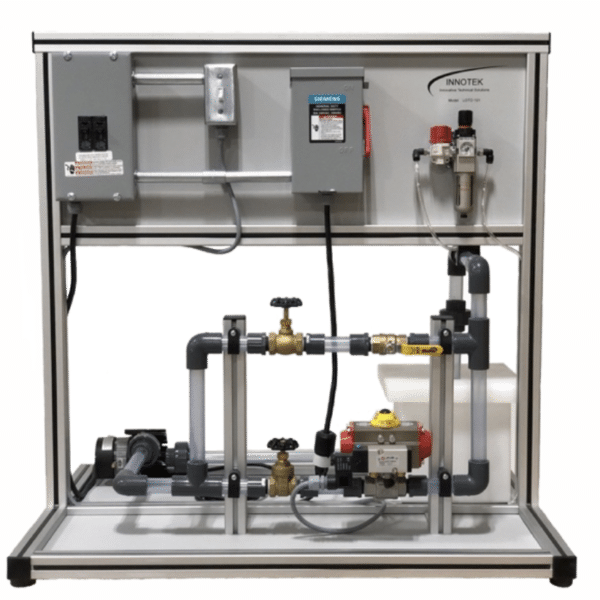

Pumps Training System

The Pumps Training System provides a hardware solution for hands-on training and study in the topic area of pumps and pump characteristics. Students learn how to operate, install, maintain, troubleshoot, analyze performance, and select centrifugal pumps.

The PUMP-200 training system teaches skills related to commonly used pumps in industrial applications, such as centrifugal pumps, which are used in almost every industry to transfer non-hydraulic fluids of various types from one place to another.

-

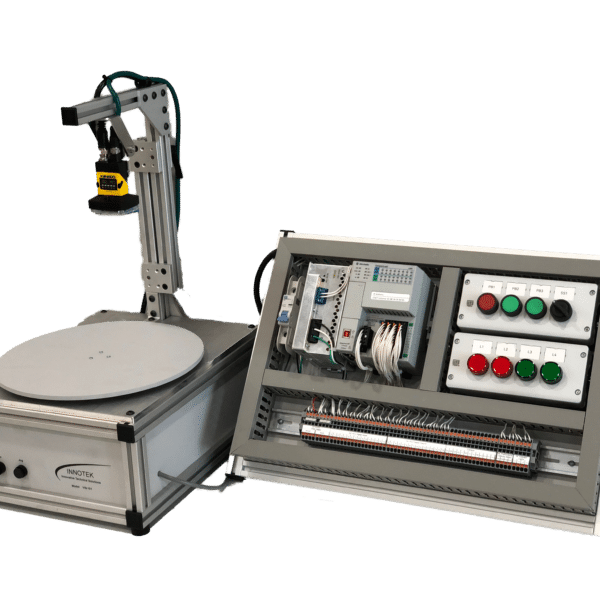

Artificial Vision Training System

Toolkit’s VIS-101 Artificial Vision Training System provides a hardware training solution for introducing the fundamentals of artificial vision to students in mechatronics, automation, robotics, and industrial technology training programs.

The hands-on training system provides components that are used in common industrial applications, allowing participants to perform experiments in camera installation, electrical connections, and configuration of vision jobs via included software.

This Artificial Vision Training System will teach fundamental concepts around artificial vision cameras and technology and will then empower students to take their newly acquired skills to more complex tasks or apply to integrated systems.

-

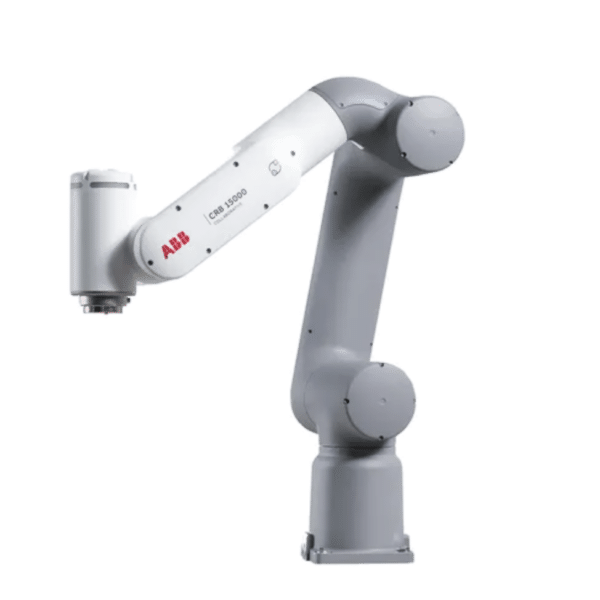

ABB GoFa CRB 15000 Collaborative Robot

Go Faster! Go Farther! Go Further! Go Train!

We are thrilled to bring ABB’s newest collaborative robot, the GoFa, with industry leading speed, precision, reach and more!

Ease-of-use is in focus here – with enhanced user-interaction capabilities, superior lead through, and ABB Wizard easy programming, training robotics and automation has never been more accessible.

Students can get hands-on industry-driven robotics experience from day 1 with unlimited training potential! Understanding the advantages of collaborative robotics and automation, machine tending, welding, pick & place, etc. has never been easier!

-

ABB IRB 14000 YuMi Collaborative Robot

The first robot to do it. Collaboratively. Uniquely and Effectively. She grabs attention and keeps it.

Best-in-class safety. Ultimate flexibility. Approachable design. ABB’s YuMi robot was engineered to work directly alongside your people and students, and boost productivity and training.

YuMi is the first truly collaborative dual-armed robot, designed for a world in which humans and robots work together. It heralds a new era of robotic coworkers which are able to work side-by-side on the same tasks as humans with extreme accuracy while ensuring the safety of those around it.

Available in single or double-arm configurations.

-

ABB IRB 1100 Industrial Robot

The ABB IRB 1100 industrial robot is a compact automation workhorse.

Aimed at increasing manufacturing productivity in highly automated industries – electronics, semiconductors, automotive, manufacturing, deburring, grinding, etc – the IRB 1100 provides up to 35% faster cycle times and best-in-class repeatability for high quality manufacturing. It consistently outperforms similar robots in terms of payload and position repeatability (RP) even when under space constraints.

For the classroom, there is no better compact industrial robot training platform with complete curriculum, training applications, industrial certification, industry-relevance, simulation softwares, and more.

-

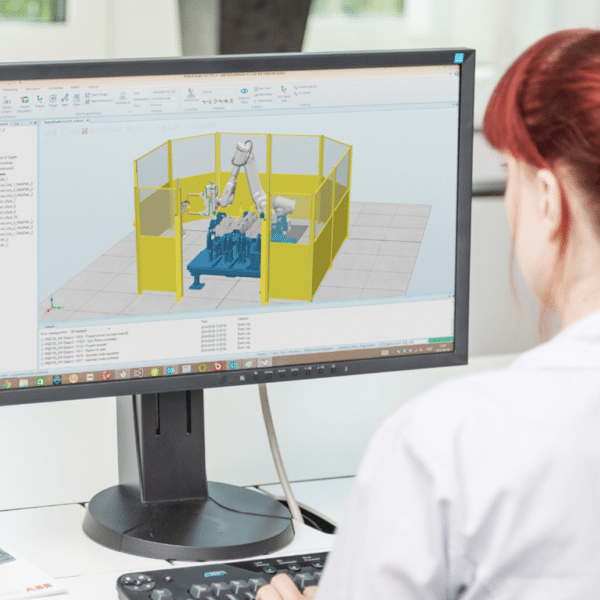

RobotStudio Simulation Software

Offline programming is one of the best ways to maximize return on investment for robot systems in both industry and education. ABB’s simulation and offline programming software, RobotStudio, allows robot programming to be done on a PC in the office without shutting down production, which allows you to perform tasks such as training, programming, and automation optimization with ease and simplicity!

The ABB Virtual Controller, an exact copy of the real software that runs your ABB robots in production, and ABB’s Teach Pendant, is built-into RobotStudio so training in the virtual environment exactly replicates real, hands-on training. This allows very realistic simulations to be performed, using real robot programs and configuration files identical to those used on the shop floor or in the classroom.

RobotStudio is the world’s most used offline programming tool for robotics comes with a holistic package of features and add-ons for various applications.

Ask Us How To Get ABB RobotStudio for FREE!