Manufacturing

Showing 13–19 of 19 results

-

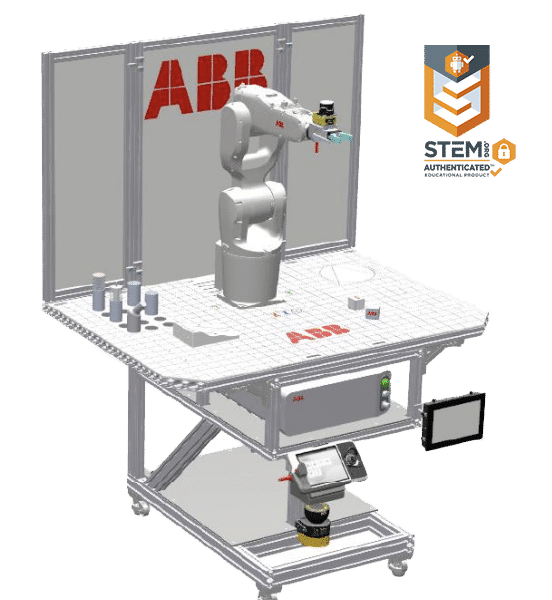

ABB Cobot FlexTrainer STEM Education Cell

Go Faster! Go Farther! Go Further! Go Train on ABB’s new Collaborative Robot, GoFa CRB 15000!

We are thrilled to bring ABB’s newest collaborative robot training system – the ABB Cobot FlexTrainer with ABB’s newest collaborative robot, the GoFa, to education.

The mobile training platform features a sleek design and various industry training applications. Paired beautifully via ABB RobotStudio, students can get hands-on training and virtual/digital solutions with AR/VR.

Now certified and authenticated by STEM.org!

-

ABB Fenceless FlexTrainer Robot Training System

The new ABB Fenceless FlexTrainer Cart was designed specifically for education. To bring students face-to-face with one of industry’s leading robots.The hands-on training cart utilizes ABB’s IRB 1200 or IRB 1100 industrial robots for practical, industry-driven skills training. The fenceless collaborative design allows open site-lines to the robot, maintaining safety with an ABB safety sensor located at the bottom of the cell.Now Certified and Authenticated by STEM.orgOther features of the FlexTrainer include:– ABB STEM Education Activity Tabletop (removable)

– Electric Gripper EoAT

– ABB 3D Printed STEM Education Activity Kit for hands-on training activities

– SMC Linear conveyor system

– HMI

– Integrated vision

– SMART Certification and Curriculum for STEM and Robotics

– Large casters for easy transportation

– Fits through a standard door

-

Robotized Assembly System

SMC’s Robotized Assembly Training System, the RAS-400, allows learners to get a real-world look at fully automated assembly environments featuring your choice of industrial robot(s).

This modular robotized assembly system consists of 4 different industrial robot stations forming a flexible automation cell. The process includes an entire series of

- Feeding

- Material handling

- Assembly verification

- Loading operations

All operations are carried out using components from different technologies (pneumatics, vacuum, sensors, etc.) that students will have to understand and apply. The primary training focus of this training system is industrial robotics, including collaborative robots.

-

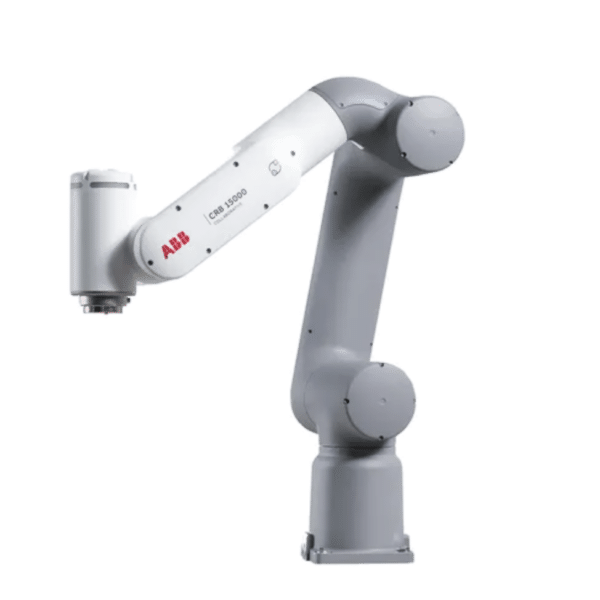

ABB GoFa CRB 15000 Collaborative Robot

Go Faster! Go Farther! Go Further! Go Train!

We are thrilled to bring ABB’s newest collaborative robot, the GoFa, with industry leading speed, precision, reach and more!

Ease-of-use is in focus here – with enhanced user-interaction capabilities, superior lead through, and ABB Wizard easy programming, training robotics and automation has never been more accessible.

Students can get hands-on industry-driven robotics experience from day 1 with unlimited training potential! Understanding the advantages of collaborative robotics and automation, machine tending, welding, pick & place, etc. has never been easier!

-

ABB IRB 14000 YuMi Collaborative Robot

The first robot to do it. Collaboratively. Uniquely and Effectively. She grabs attention and keeps it.

Best-in-class safety. Ultimate flexibility. Approachable design. ABB’s YuMi robot was engineered to work directly alongside your people and students, and boost productivity and training.

YuMi is the first truly collaborative dual-armed robot, designed for a world in which humans and robots work together. It heralds a new era of robotic coworkers which are able to work side-by-side on the same tasks as humans with extreme accuracy while ensuring the safety of those around it.

Available in single or double-arm configurations.

-

ABB IRB 1100 Industrial Robot

The ABB IRB 1100 industrial robot is a compact automation workhorse.

Aimed at increasing manufacturing productivity in highly automated industries – electronics, semiconductors, automotive, manufacturing, deburring, grinding, etc – the IRB 1100 provides up to 35% faster cycle times and best-in-class repeatability for high quality manufacturing. It consistently outperforms similar robots in terms of payload and position repeatability (RP) even when under space constraints.

For the classroom, there is no better compact industrial robot training platform with complete curriculum, training applications, industrial certification, industry-relevance, simulation softwares, and more.

-

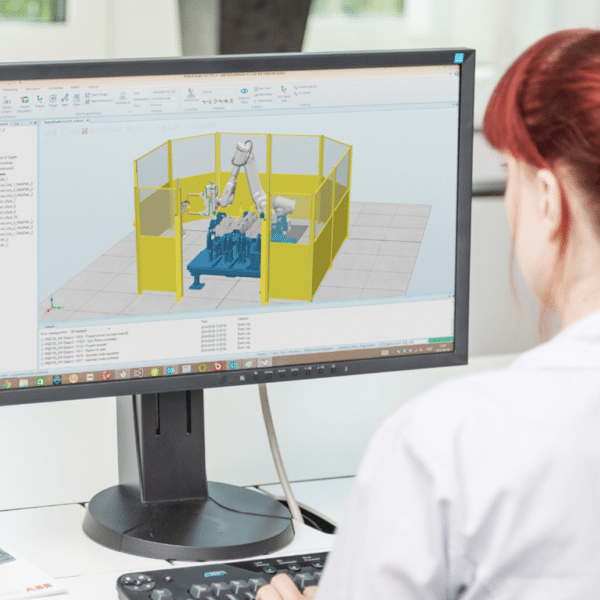

RobotStudio Simulation Software

Offline programming is one of the best ways to maximize return on investment for robot systems in both industry and education. ABB’s simulation and offline programming software, RobotStudio, allows robot programming to be done on a PC in the office without shutting down production, which allows you to perform tasks such as training, programming, and automation optimization with ease and simplicity!

The ABB Virtual Controller, an exact copy of the real software that runs your ABB robots in production, and ABB’s Teach Pendant, is built-into RobotStudio so training in the virtual environment exactly replicates real, hands-on training. This allows very realistic simulations to be performed, using real robot programs and configuration files identical to those used on the shop floor or in the classroom.

RobotStudio is the world’s most used offline programming tool for robotics comes with a holistic package of features and add-ons for various applications.

Ask Us How To Get ABB RobotStudio for FREE!