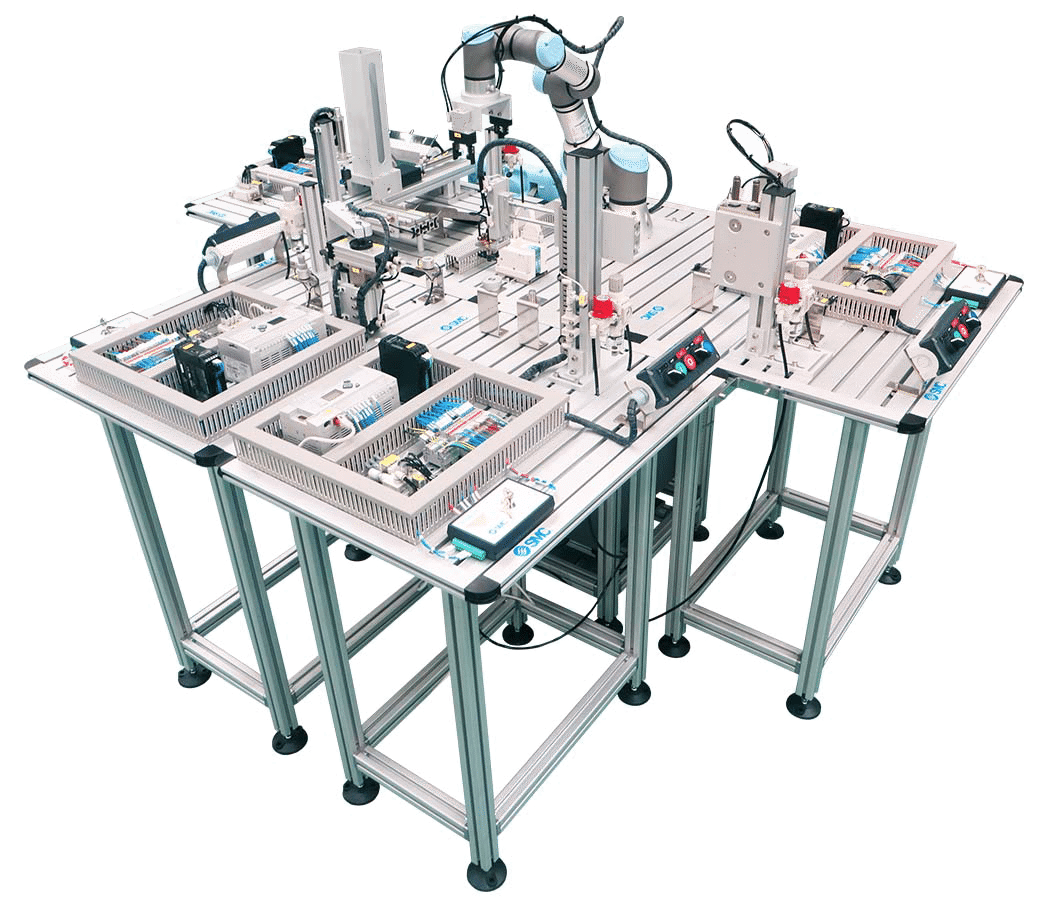

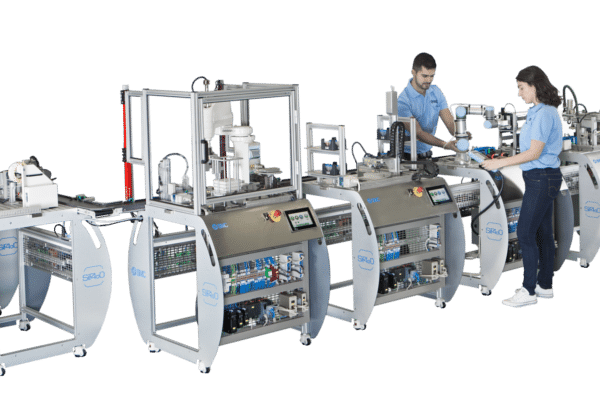

Description

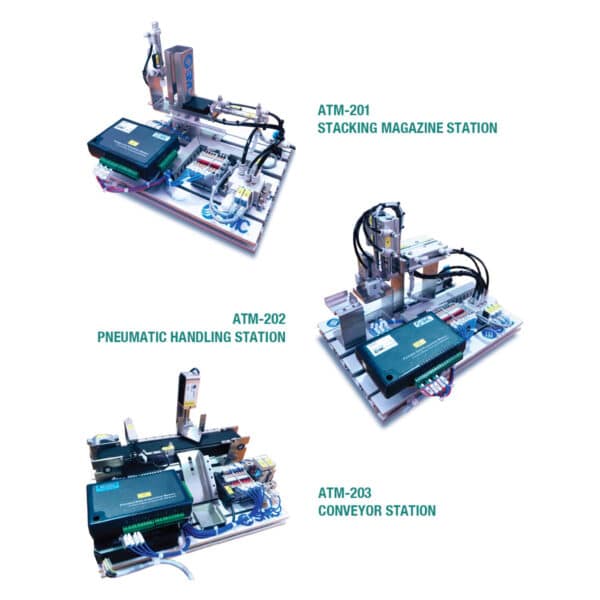

The design of the MAS-200 allows simple and quick extraction of the stations, assisting individual work with each of them. All the components of which the MAS-200 is comprised are used in industry, allowing the user to gain detailed knowledge of the technologies currently used in automated industry.

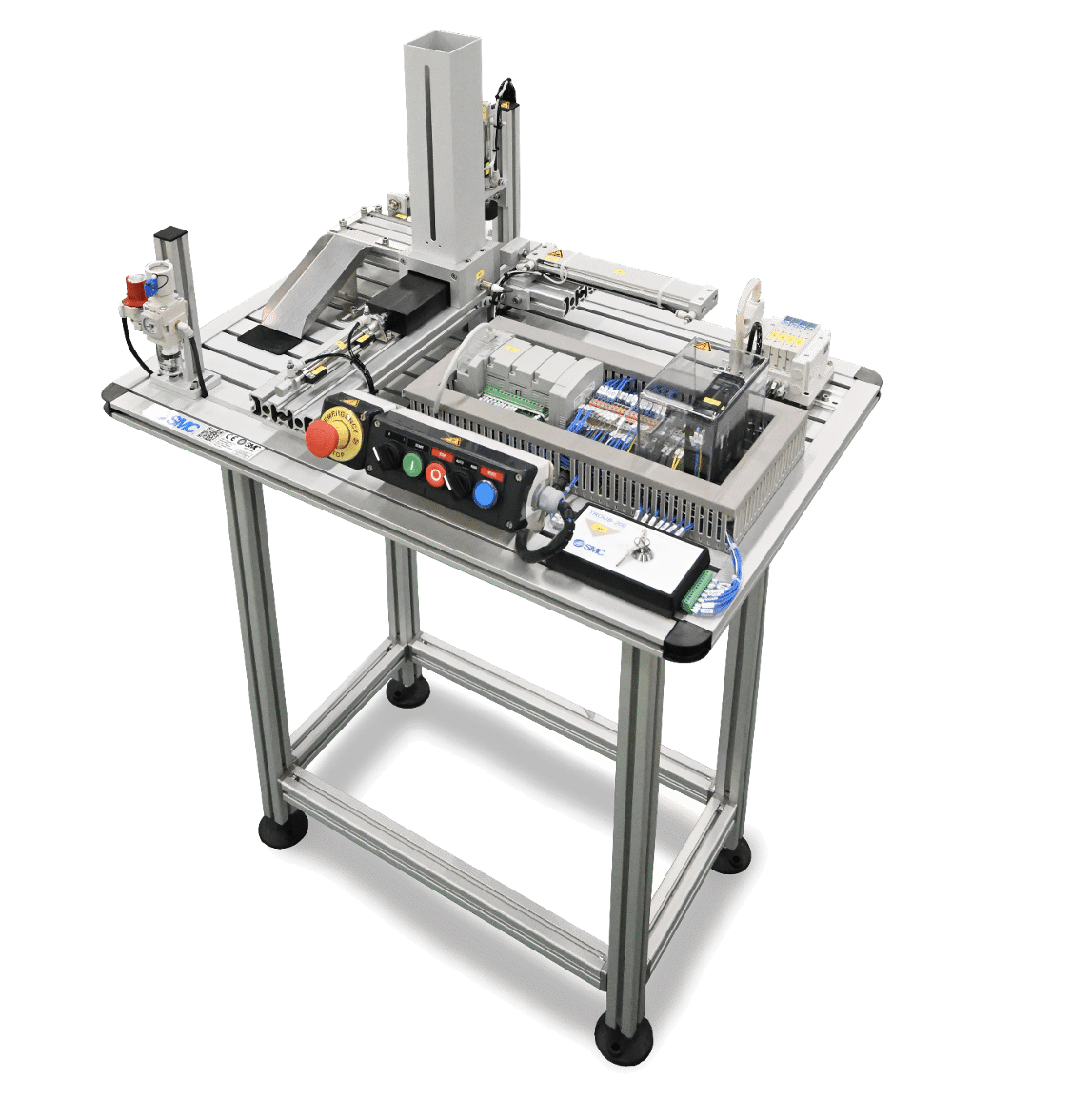

MAS-201: Part Feeder with Detection and Ejection of Incorrect Parts

The function of the station consists of feeding a part and expelling it if it is not in the right position.

– Air treatment unit: Comprised of a manual control 3/2 valve, filter and pressure controller with a pressure gauge.

– Control keypad: It includes a green start button, red stop button, blue reset button with a failure light and on/off and manual/automatic switches.

Part feeder module: This module has a gravity feeder in which the anodized aluminum parts are stored on top of each other, so that when the part at the bottom of the pile is fed the rest fall down due to gravity. The part at the bottom of the pile is removed using a pneumatic cylinder that drives a pusher adapted to the size of the part. An inductive detector signals that there is a part in the warehouse. The components in this module have the following characteristics:

– Storage capacity: minimum 10 parts.

– Actuators: 1 double acting pneumatic pusher cylinder, Ø16 and 100mm stroke, with speed controllers and initial and final position switches and Controlled by a single 5/2 solenoid valve.

– Sensors: 2 auto switches, Reed type. 1 Inductive detector.

Position verification module

A cylinder equipped with a cylinder part screwed into the end of the rod that is inserted in the 32mm diameter opening on the top of the anodized aluminum part verifies that the part is in the right position. The components in this module have the following characteristics:

– Actuators: 1 double acting pneumatic cylinder, Ø12 and 50mm stroke, with speed controllers and final position switches. Controlled by a single 5/2 solenoid valve.

– Sensors: 1 auto switch, Reed type.

Displacement module

Once the position of the anodized aluminum part has been verified, this module displaces the part to an unloading area. The part is displaced by a pneumatic cylinder that drives a pusher adapted to the size of the anodized aluminum part. The components in this module have the following characteristics:

– Actuators: 1 rectangular pneumatic pusher cylinder, Ø25 and 200mm stroke, with speed controllers and final position switches. Controlled by a single 5/2 solenoid valve.

– Sensors: 1 auto switch, Reed type.

Incorrect part rejection module

If the “position verification module” detects that the anodized aluminum part is not in the right position, this module ejects the part through a pusher cylinder onto a stainless steel ramp, in order to leave the path unobstructed for the other parts. The components in this module have the following characteristics:

– Actuators:1 single acting ejecting cylinder, Ø10, 15mm stroke, with speed controller. Controlled by a single 3/2 solenoid valve.

Breakdown generation station:

The module is equipped with a breakdown generation system which generates up to 16 non-destructive anomalies that are activated by switches. This system is inside a locked box.

MAS-202: Positioning of the Lid Station

The function of the station is to transfer the part from a starting area to an unloading area, using three vacuum pads. These areas are recreated using both parts made from stainless steel.

– Air treatment unit:

Comprising a manual control 3/2 valve, filter and pressure controller with a pressure gauge.

– Control keypad: It includes a green start button, red stop button, blue reset button with a failure light and on/off and manual/automatic cycle switches.

Part transfer module: Comprising two interconnected parallel-rod cylinders forming two shafts, one horizontal and one vertical, that includes a plate with three buffer vacuum pads at the end of the rods. A vacuum sensor or switch signals that there is a part in the feeder position. The components in this module have the following characteristics:

– Actuators:

Horizontal shaft: – Double acting pneumatic parallel-rod cylinder, Ø15 and 100mm stroke, with speed controllers and initial and final position switches. Controlled by a double 5/2 solenoid valve.

Vertical shaft: – Double acting pneumatic parallel-rod cylinder, Ø10 and 50 mm stroke, with speed controllers and initial and final position switches. Controlled by a single 5/2 solenoid valve.

– Fixing arm: 3 Ø8 vacuum pads, with vacuum ejector. Controlled by a single 3/2 solenoid valve.

– Sensors: 4 auto switches, Reed type. 1 PNP output vacuum switch.

Breakdown generation station:

The module is equipped with a breakdown generation system which generates up to 16 non-destructive anomalies that are activated by switches. This system is inside a locked box.

MAS-203: Insertion of the Bearing Station

The function of the station is to transfer the part from a starting area to an unloading area, using an internal gripper. These areas are recreated using both parts made from stainless steel.

– Air treatment unit: Comprising a manual control 3/2 valve, filter and pressure controller with a pressure gauge.

– Control keypad: It includes a green start button, red stop button, blue reset button with a failure light and on/off and manual/automatic cycle switches.

Part transfer module: Comprising a rotary pneumatic actuator with a pneumatic gripper at the end of a fixing arm. A barrier photocell signals that there is a part in the feeder position. The components in this module have the following characteristics:

– Actuators:

1 pneumatic rotary actuator: double rack and pinion, Ø25, µmax 180º with speed controllers and 0º, 90º, and

180º position switch. Controlled by a closed-centre 5/3 solenoid valve.

1 Fixing arm: Pneumatic grippers with two parallel-opening jaws. Controlled by a single 5/2 solenoid valve.

– Sensors: 3 auto switches, Reed type. 2 Barrier photocells.

Breakdown generation station:

The module is equipped with a breakdown generation system which generates up to 16 non-destructive anomalies that are activated by switches. This system is inside a locked box.

MAS-204: Insertion of the Shaft Station

The function of the station is to transfer the part from a starting area to an unloading area. These areas are recreated using both parts made from stainless steel. The movement is through a rotolinear actuator that displaces an external gripper.

– Air treatment unit: Comprising a manual control 3/2 valve, filter and pressure controller with a pressure gauge.

– Control keypad: It includes a green start button, red stop button, blue reset button with a failure light and on/off and manual/automatic switches.

Part transfer module: Comprising a rotolinear pneumatic actuator, with linear and rotary drive, with a pneumatic gripper at the end of a fixing arm. A barrier photocell signals that there is a part in the feeder position. The components in this module have the following characteristics:

– Actuators:

Compact linear and rotary drive cylinder, Ø32, 25mm stroke, with speed controllers and initial and end of stroke position switches during linear movement

and 0º and 180º during rotary movement. Controlled by two single 5/2 solenoid valves.

Fixing arm: Pneumatic gripper with two parallel-opening jaws. Controlled by a single 5/2 solenoid valve.

– Sensors: 4 auto switches. Reed type. 2 solid state auto switches. 2 fibre optic photocells.

Breakdown generation station:

The module is equipped with a breakdown generation system which generates up to 16 non-destructive anomalies that are activated by switches. This system is inside a locked box.

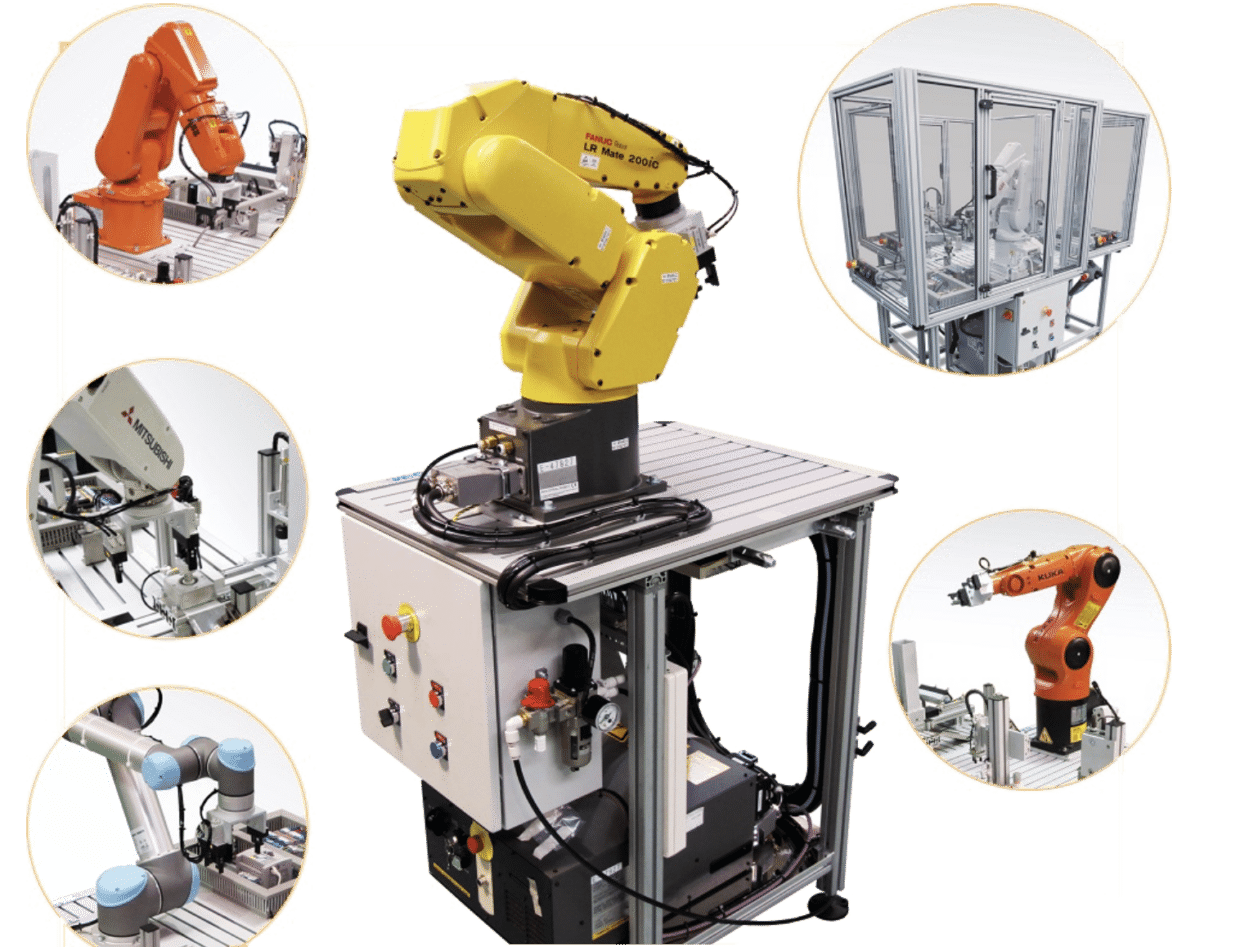

MAS-205A: Pneumatic Part Transfer Station

The function of the station is to transfer the parts between the stations to assemble and disassemble a turning mechanism and to synchronize communications between the controls of the other stations.

This station handles the following parts:

- Bearing

- Shaft

- Lid

Module for handling parts by external gripper.

This part handling module consists of two Cartesian axes driven by two pneumatic actuators, with final handling by a pneumatic gripper that clamps the parts to be handled on the outside, with jaws adapted to the size of those parts.

– Actuators:

Horizontal shaft: Double acting double rod cylinder, Ø20 and 150mm stroke, with speed controllers and initial and final position switches. Controlled by a single 5/2 solenoid valve.

Vertical shaft: Double acting double rod cylinder, Ø15 and 50mm stroke, with speed controllers and initial and final position switches. Controlled by a single 5/2 solenoid valve.

Fixing arm: Pneumatic grippers with two parallel-opening jaws. Controlled by a single 5/2 solenoid valve.

– Sensors: Auto switches, Reed type.

Module for handling parts by internal gripper.

This part handling module consists of two Cartesian axes driven by two pneumatic actuators, with final handling by a pneumatic gripper that clamps the parts to be handled on the inside, with jaws adapted to the size of those parts.

– Actuators:

Horizontal shaft: Double acting double rod cylinder, Ø20 and 150mm stroke, with speed controllers and initial and final position switches. Controlled by a single 5/2 solenoid valve.

Vertical shaft: Double acting double rod cylinder, Ø15 and 50mm stroke, with speed controllers and initial and final position switches. Controlled by a single 5/2 solenoid valve.

– Fixing arm: Pneumatic grippers with two parallel-opening jaws. Controlled by a single 5/2 solenoid valve.

– Sensors: Auto switches, Reed type.

Module for dividing plate

This module is used as an alternative rotary drive system, such that with each rotary movement it advances a certain number of degrees. To achieve this, a pneumatic pusher cylinder with oscillating drive and another two stopper cylinders operating alternately is included. To verify the position of the dividing plate, a barcode reader is used.

– Actuators:

Double acting pusher cylinder, Ø25 and 40mm stroke, with speed controllers and final position switch. Controlled by a single 5/2 solenoid valve.

Double acting clamp cylinder, Ø16 and 10mm stroke, with fittings. Controlled by a single 5/2 solenoid valve.

Double acting clamp cylinder, Ø16 and 10mm stroke, with fittings. Controlled by a single 5/2 solenoid valve.

Double acting cylinder with guides, Ø12 and 20 mm stroke, with speed controllers and final position switch. Controlled by a single 5/2 solenoid valve.

– Sensors:

– Auto switch, Reed type.

– Bar code reader

Air treatment unit:

It includes a compressed air general intake with an air treatment unit, with a filter, pressure controller, pressure gauge and manual valve.

Control and command cabinet (master cabinet)

A locked cabinet houses the station’s control panel. There are buttons on it, including: start, stop and reset buttons, manual/automatic switch, failure indicator light, main switch and endorsed emergency stop button. The following components are inside:

– 1 24VDC 60W power supply.

– Magneto-thermal switch.

– 110-240VAC 50/60Hz single-phase mains connection.

All of the pneumatic cables and tubing are properly identified and labelled at both ends.

The electrical and pneumatic control required for the handling device to operate in stand-alone mode is included on the station desktop, with the following components:

– Electrical connection terminal box with power input and coded I/O.

– Block of solenoid valves.

Distribution module

This station has a plate at the bottom of it to allow the distribution of the power network, the compressed air and the communication network to all the stations. The air, power and communications connections have an accessible layout to ease connection with the relevant station connections.

Breakdown generation station:

The module is equipped with a breakdown generation system which generates up to 16 non-destructive anomalies that are activated by switches. This system is inside a locked box.

The MAS-200 system includes an optional SCADA tool which enables:

- Access to the status of the various field devices.

- Display, management and storage in the PC of information collected during the process.

- Control and modification of the process in real time.

- Display of the various phases of the process via a graphical interface.

- Recognition of alarms in the event of system failures.

- Generation of data logs and statistical data.