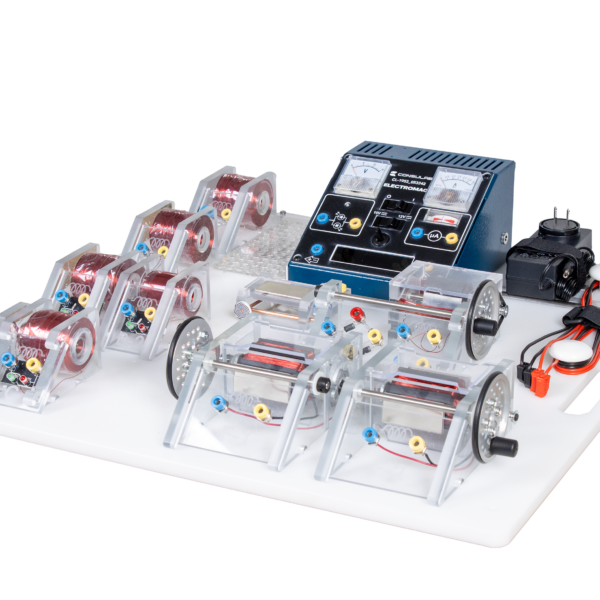

Description

Educational Advantages

- Demonstration of systems to groups of students without the access limitations of a complete vehicle

- Engine and A/C systems respond to inserted faults with real world symptoms, OEM DTC’s and check engine light operation

- Visually demonstrates refrigerant change of state

- Hands on demonstration of electric assist power steering

Standard Equipment and Features

- Automatic transaxle (4T45E)

- OBDII data link connector

- Integrated ECM breakout box w/ test points and ECM terminals identified with OEM terminology

- Refrigerant high and low-side pressure gauges

- Exhaust system w/ catalytic converter

- Safety covers for all rotating components

- Fuel tank

- 12V battery included with automatic charger

- HD square tubing mobile stand with phenol casters (2-fixed and 2- swivel w/locks)

- Emergency stop button

- Manual fault box for engine performance

Fully Functional OEM Vehicle Systems

- Sequential fuel injection w/electronic ignition

- Electronic ignition

- CAN (controller area network)

- ETC (electronic throttle control)

- Adapting charging

- Starting

- EVAP (evaporative emissions) w/test port

- Underhood power distribution center

Optional Equipment

- Electronic programmable fault box with 16 faults capable of programming intermittent fault insertion

- Coolant flow sight glass

- TXV H-Block A/C system with sight glasses

- Manual fault box for A/C

- Refrigerant high and low-side pressure gauges

- Electric assist power steering system w/hand grips to demonstrate system function

- Protective instrument panel cover

- Vinyl dust cover

- Fork lift bars

- Secondary key for engine bench with programming

Applications

- 2010-2009 Chevrolet Cobalt or Pontiac G5 with vehicle identification number (VIN) provided

- 2.2L ECOTEC global engine platform