Description

What is a Digital Twin?

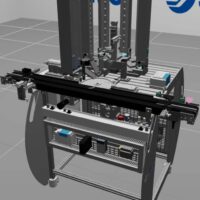

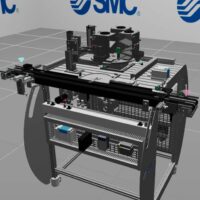

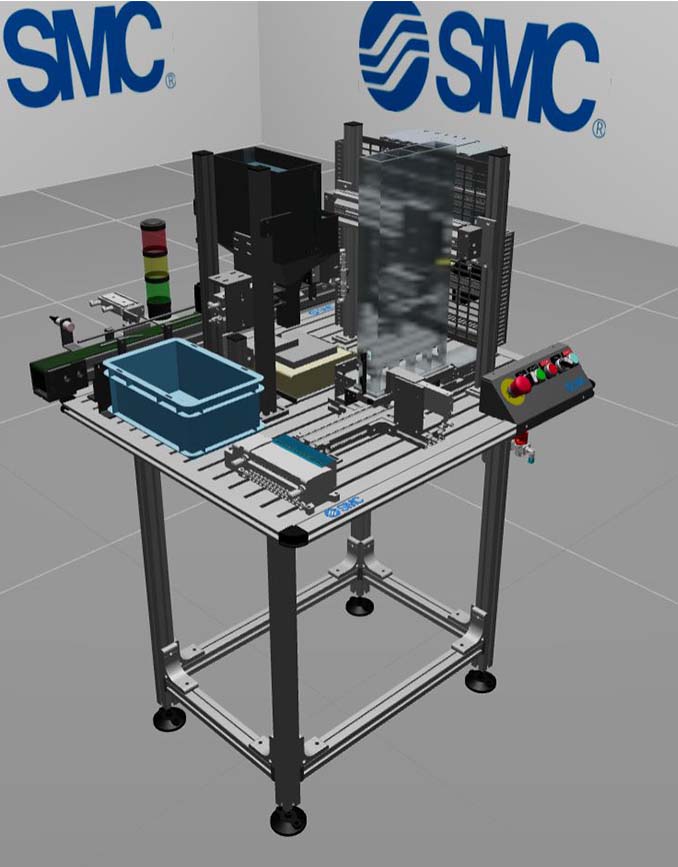

In its simplest form, a digital twin is a digital representation of a real physical system. An environment where the physical and virtual worlds meet to form and act as one.

Through connectivity using the Industrial Internet of Things (IIoT), real-time data is perfectly synchronized between physical and virtual systems to create an environment where conditions and scenarios can be more than simply simulated; they can be emulated, tested, hypothesized and proven, and deployed. We refer to this as a “Digital Shadow.”

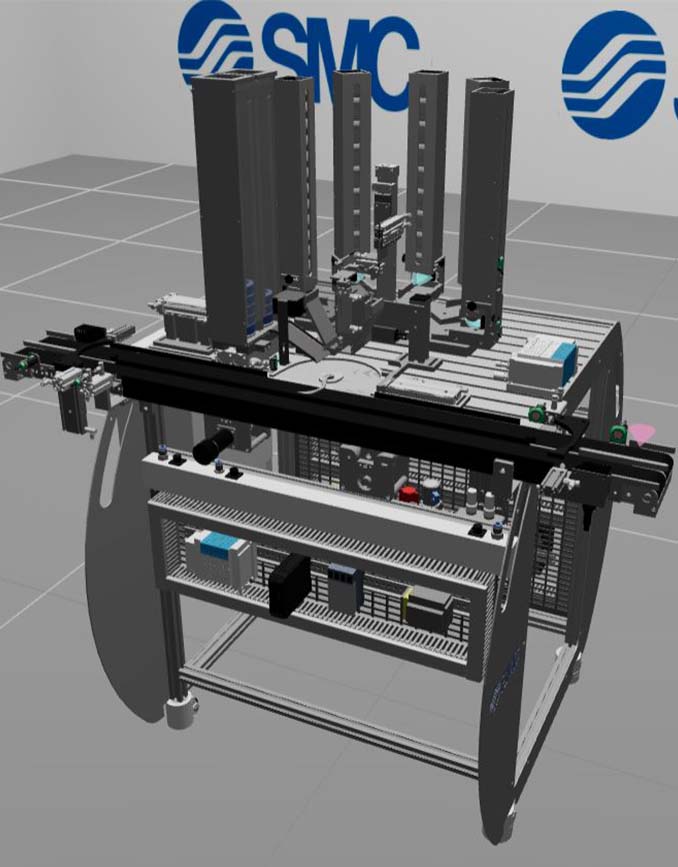

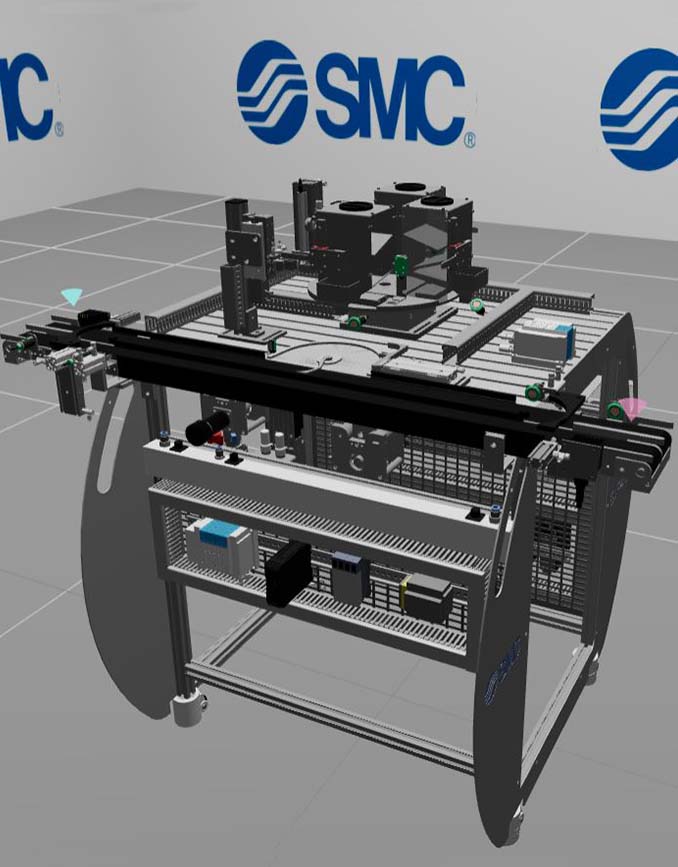

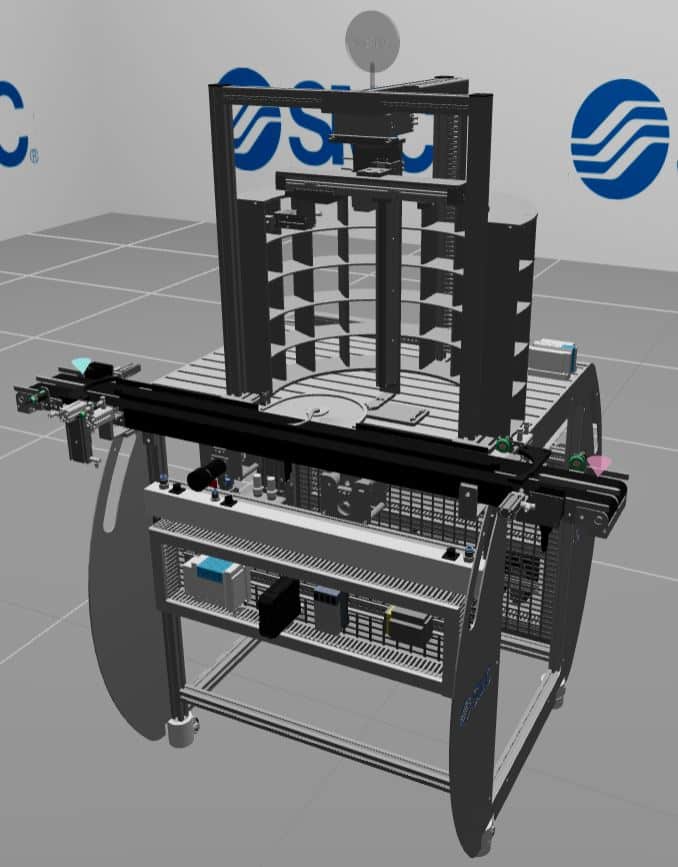

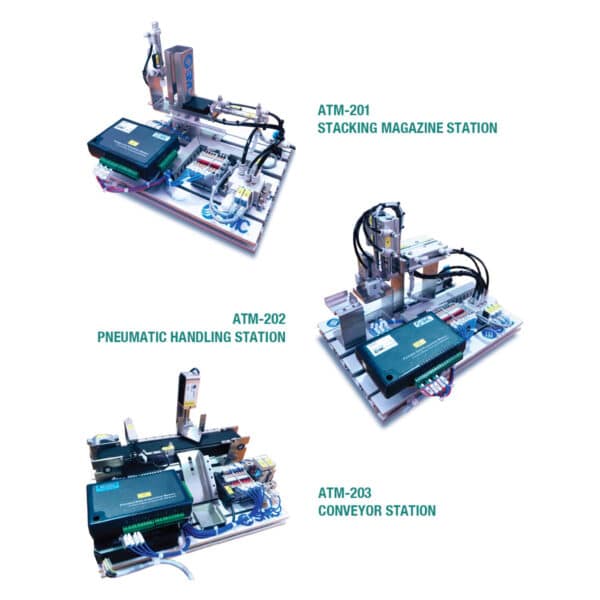

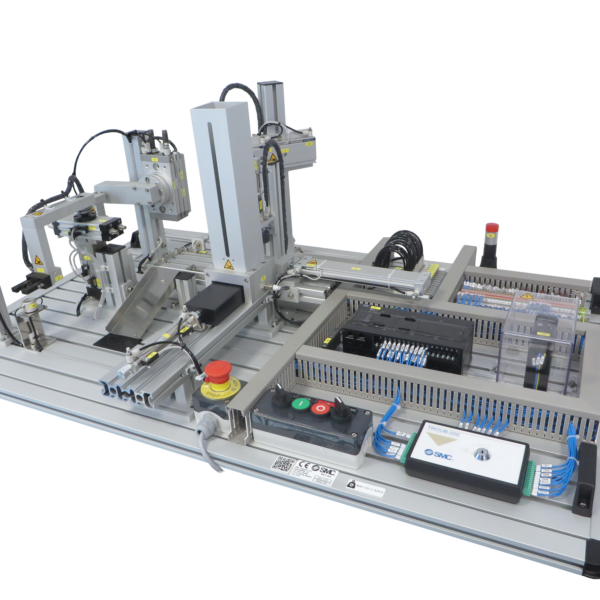

Within the SMCTwin-400 Digital Twin environment, you can do everything from randomizing conditions to fully controlling every single aspect – down to the very physics – of the environment or system.

Why are Digital Twins Valuable?

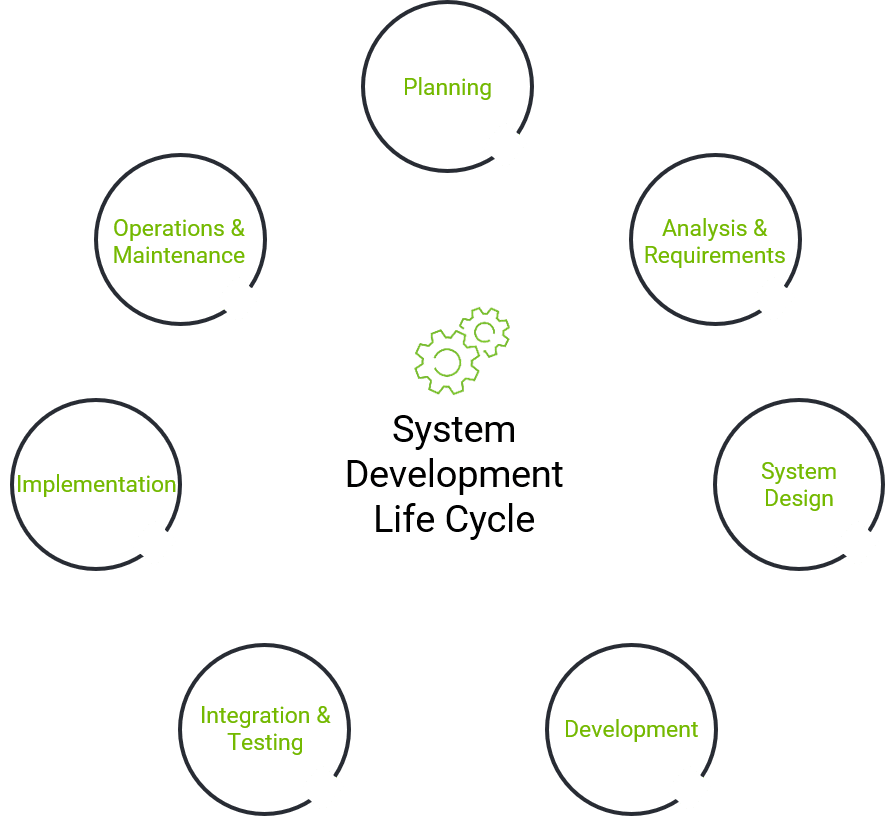

Imagine what you can learn about a manufacturing system, process, or environment by controlling time itself and analyzing system performances. You could rewind, stop, slow down, or speed up entire manufacturing processes and record years of data in minutes.

- You can re-organize, re-position, re-program, and re-think your automation systems.

- You can plan, map, and structure automation environments before deployment.

- The possibilities and benefits are truly limitless.

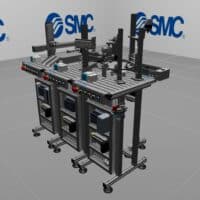

SMCTwin-400 is the ideal and versatile training solution for acquiring skills in:

- Equipment Analysis

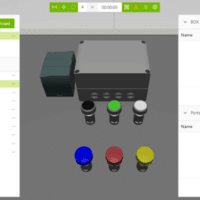

- PLC Programming

- HMI Programming

- Design and Interpretation of Documentation

- Systems Modeling

All systems and models operate and function in the exact same manner as they would in a real industrial environment!

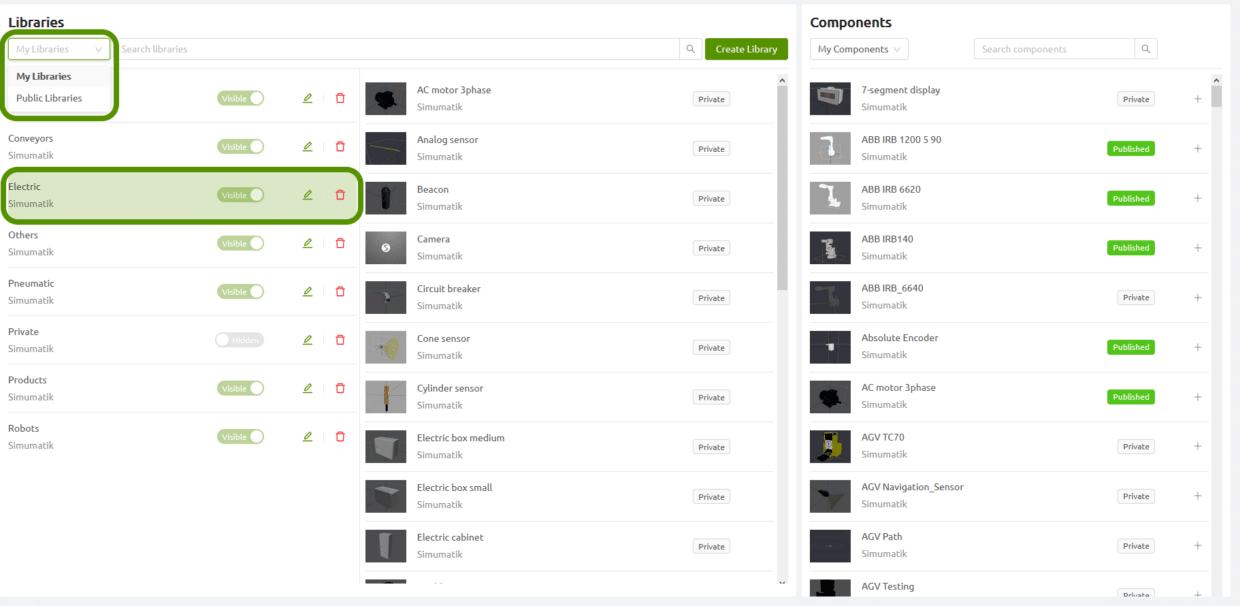

Complete library with all the components of each model: Users are able to visualize and use each component that makes up each SMC training system model and access their information.

The Perfect Complement to Classroom/Lab Activities

- See inside each component and truly discover how they work – a lifelike cutaway that works!

- The possibility of using emulations to make teaching more attractive and intuitive.

- Create, make modifications to, and test PLC programs with no risk of damaging equipment or downtime!

Be part of a community: The components or systems created can be stored privately or publicly. The latter allows the created components or systems to be shared with other people in other organizations. In this way, it is also possible to use components created by other users.