Mechanical

Mechanical technologies and concepts are another foundational technology skillset that can differentiate a good student from a mediocre student, and another important backbone of so many industrial professions.

Mechanical technologies influence all modern integrated manufacturing systems, vehicles, and careers.

With Toolkit, we make sure students are well-prepared with mechanical concepts and skills by introducing them to industry-relevant hands-on training systems, simulators, and software solutions that ensure a successful future in industry.

Discover the mechanical training systems from Toolkit that teach hands-on skills like drives, motors, alignments, gears, pulleys, and more.

Showing all 8 results

-

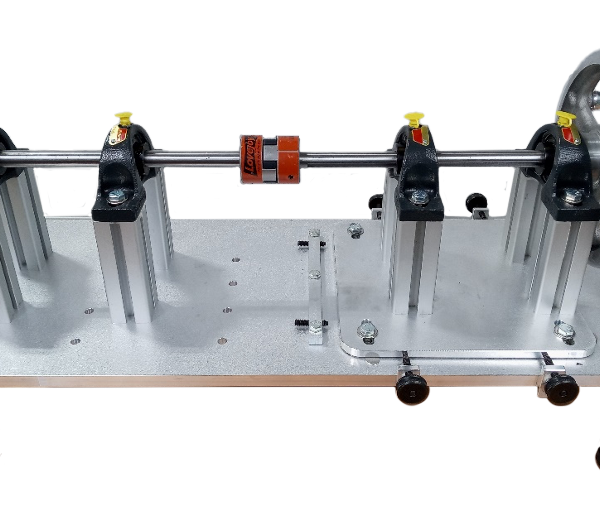

Tabletop Mechanical Shaft Alignment Trainer

Explore the low-cost, tabletop Mechanical Shaft Alignment Trainer from Innotek. This is a low cost alternative to the SMC Full Mechanical Drives Training System, the MEC-200. Robust but small enough store easily or take to off-site training locations.

The flexible design allows learners to explore and practice various alignment techniques and explore various outcomes and impacts of their actions.

-

SMC Mechanical Training System

The SMC MEC-200 Mechanical Training system provides participants with hardware allowing for hands-on experiments in the use, troubleshooting, installation, and maintenance of mechanical drive technologies.

Topic coverage includes mechanical shaft alignment, pulley alignment, belt installation, sprocket alignment, chain installation, gear alignment practices and speed ratios, and is all based around practical, real-world activities and tasks.

Learners will practice industry-driven hands-on skills such as leveling an electric motor, calculating mechanical efficiency, installation of jaw couplings, and installation and alignment of a sleeve coupling and shaft, and more.

-

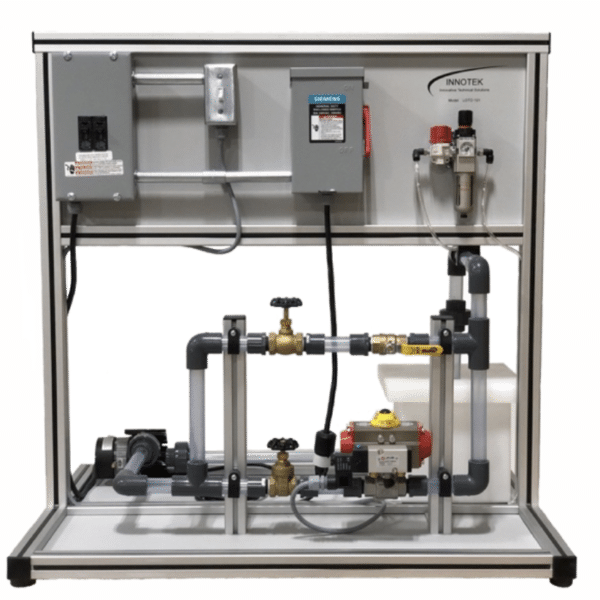

Lock-Out Tag-Out Training System

The Innotek Lockout-Tagout Training system provides learners with hardware allowing for demonstration and assessment of LOTO procedures. Lock-Out Tag-Out trainer puts students in the front seat of proper safety procedures in industrial workplaces.

According to the Occupational Safety and Health Administration (OSHA), lock-out/tag-out is one of the Top 10 “”Most Serious Violations”” and “”Most Often Cited Violations”” in industrial workplaces. LOTO must be taken seriously, as lives could be at stake. Workers maintaining equipment can be seriously injured from the unexpected energization of, release of stored energy from, or startup of equipment.

Proper Lock-Out Tag-Out procedures establish standards for the shutdown of equipment, so that energy sources can be isolated to prevent the release of potentially-hazardous energy during routine maintenance activities. Following proper LOTO procedures helps workers to avoid preventable workplace accidents and injuries.

The LOTO-101 training system is a functional system and operates a pump/tank circuit with various power sources and valves for multiple training scenarios. All required safety devices are included with the system for both electrical and mechanical devices.

-

Pumps Training System

The Pumps Training System provides a hardware solution for hands-on training and study in the topic area of pumps and pump characteristics. Students learn how to operate, install, maintain, troubleshoot, analyze performance, and select centrifugal pumps.

The PUMP-200 training system teaches skills related to commonly used pumps in industrial applications, such as centrifugal pumps, which are used in almost every industry to transfer non-hydraulic fluids of various types from one place to another.

-

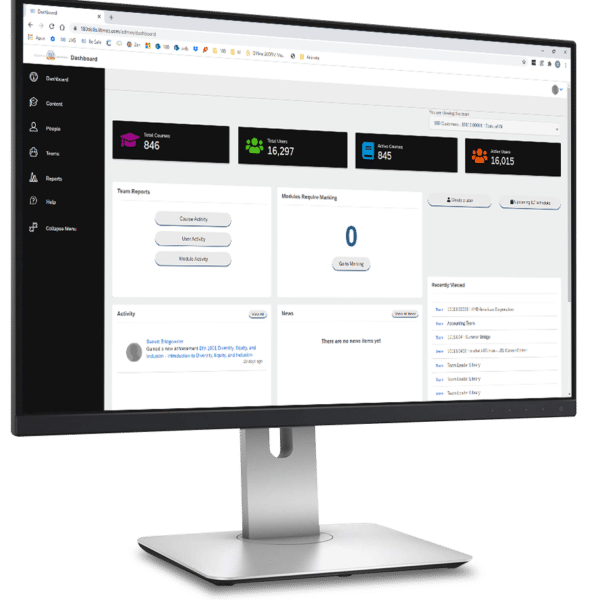

CTE + Workforce eLearning

Toolkit is proud to partner with Valor, 180 Skills, and SMC to bring you the most complete, thorough, and comprehensive eLearning solution for Career and Technical Education. An AWARD-WINNING Learning System for CTE, Workforce Development, and Industry Training.

Web-based eLearning content in over 900 courses – ranging from Career and Technical Education skills, Workforce Development training, Soft Skills development, and more!

Our new eLearning is the most comprehensive skills-based training program out there for real-world skills, certifications, and job-ready outcomes.

Over 600 Technical Skills Courses!

Over 200 Employability and Soft Skills Courses!

Over 80 Quality + Compliance Skills Courses!

-

SMC eLearning

SMC eLEARNING-200 is a flexible, web-based learning platform for skills-based, industry-driven learning to take place anywhere, anytime there is the motivation to learn!

Users can develop skills and theoretical knowledge around Automation and Technical topics such as Robotics, PLCs, Electrical, Pneumatics, Hydraulics, Motors, Sensors and More.

-

SMCTwin-400 Digital Twin Software

We are thrilled to bring the first Digital Twin training software to schools across the globe with SMC’s revolutionary Digital Twin-400 software.

SMCTwin-400 is an online, one-for-one emulation platform where students will be able to develop and control digital twin models. All models operate and behave in the exact manner in which they would in the real world, giving students a never-before-seen lens to view automation and industry.

This true Industry 4.0 software provides students with the ability to access virtual replicas of real SMC training equipment and industrial components, allowing them to safely experience industrial technologies and processes, monitor all of the system’s electrical and pneumatic values, program and create various PLC/HMI programs, and witness the results in real time!

-

Hand Tools Fundamentals Training Bench

TOOLKIT’s Hand Tools Fundamentals Training System is a versatile foundational training package key to careers in the modern Construction industry.

Paired with hands-on lab activities, this courseware will help to teach students fundamental concepts in measurement, cutting, power tools, fasteners, hand tools, material handling, workplace and soft skills, etc.

The optional workbench provides additional storage capabilities and doubles as a student activity platform.