Description

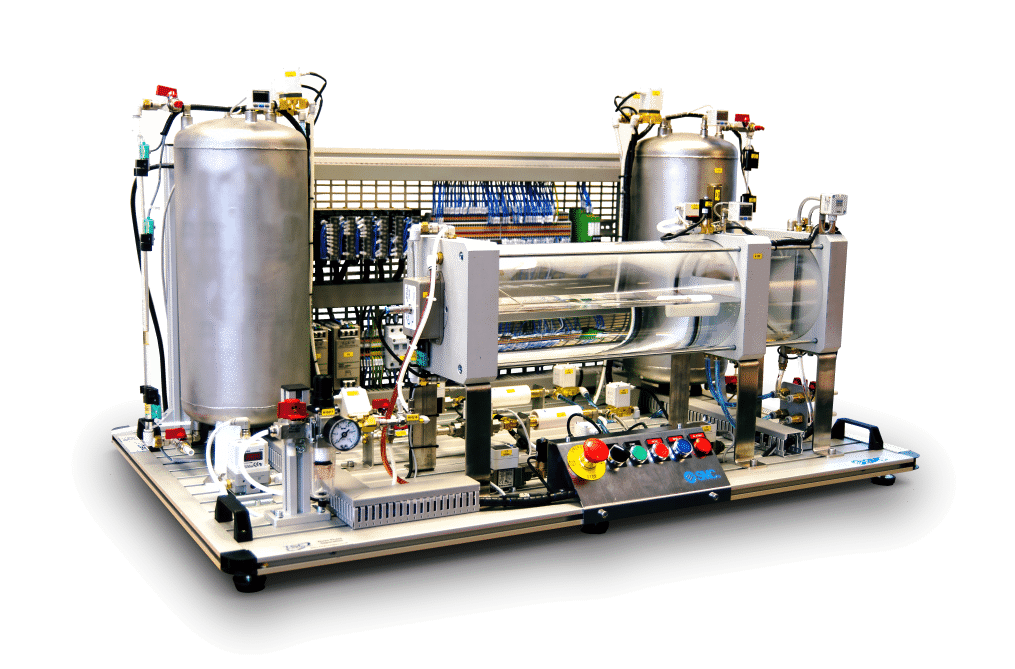

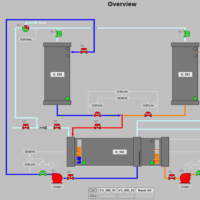

SMC’s low cost, tabletop 3 Phase Separator training system delivers a wide range of basic and advanced technologies, fully integrated with Dynamic System Control software.

TPS 200 is a Desktop Three Phase Separator that utilizes standard industrial hardware, non-toxic oil and a PC-based DCS style control interface.

Fundamentals

TPS-200 system allows the user to explore more about the fundamentals of three phase separation. The oil, gas, water separation basics can be learned with this system:

- Physical layout (visual and practical)

- Flow vs. residence time (visual and theoretical)

- Flow vs. compositions (visual and using sim model)

- Pressure vs. flow/gas rates (visual and theoretical).

- Pressure vs. compositions (using sim model).

- Temperature vs. compositions (using sim model).

Activities

With the new TPS-200 system the user will be able to work and develop different skills using the following control systems:

- Transmitters (pressure, flow, level and interface level).

- Level Control (several sensor types, PID tuning and variable cascade control).

- Pressure control (PID tuning and several sensor types).

- Flow control (fluid flow control, ratio flow control and direct flow control).

- PLC system (PLC ladder may be viewed and limit switches).

- Safety Systems (ESD and cause and effect)

Separation Basics include:

- Physical layout – visual and practical

- Flow vs. Residence Time – visual and theoretical

- Flow vs Composites – using sim model (multiple); visual (2 component)

- Pressure vs Flow/Gas Rates – visual and theoretical

- Press vs Composites – using sim model (multiples)

- Temp vs Compositions – using sim model (multiple)

DCS System includes:

- Introduction to Graphics Style

- Line color / pipe color

- Line following

- Several Control Type Examples

- Measurement Unit Conversion

- Alarms

- Trend Displays

- Action Replays

- Pre-Prepared Sequencing

Simulation Model includes:

- Separation Fundamentals

- Multiple Component

- DCS Introduction

- Practice the Procedures

- Practice the Measurements

- Effect of Temperature

- Tune the Controllers

- Safety Systems

Control System includes:

- Transmitters

- Level Control

- Pressure Control

- Flow Control

- PLC System

- Safety System