Description

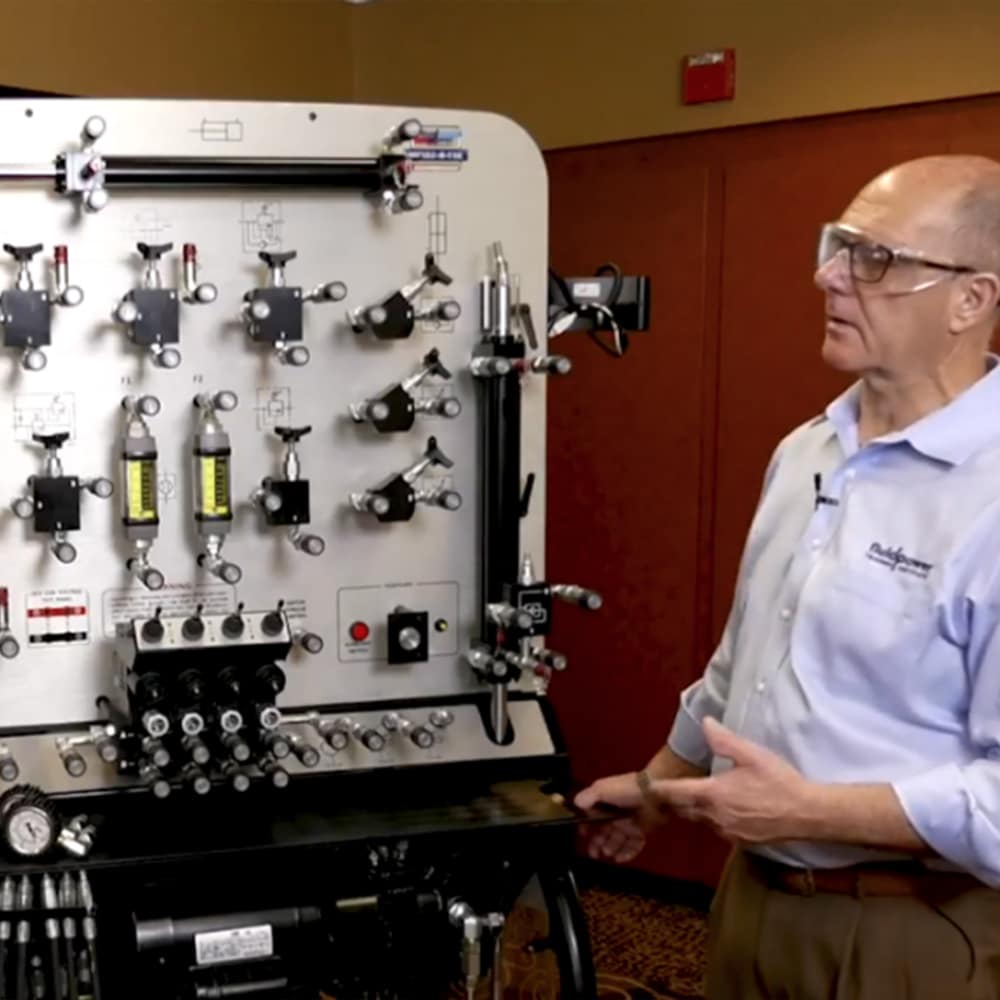

The electronically-controlled, infinitely variable, wheel-load system allows students to drive the hydrostatic transmission under any type of operating condition, i.e., up-hill, downhill, level surface – it can even simulate a runaway condition.

Learning Activities

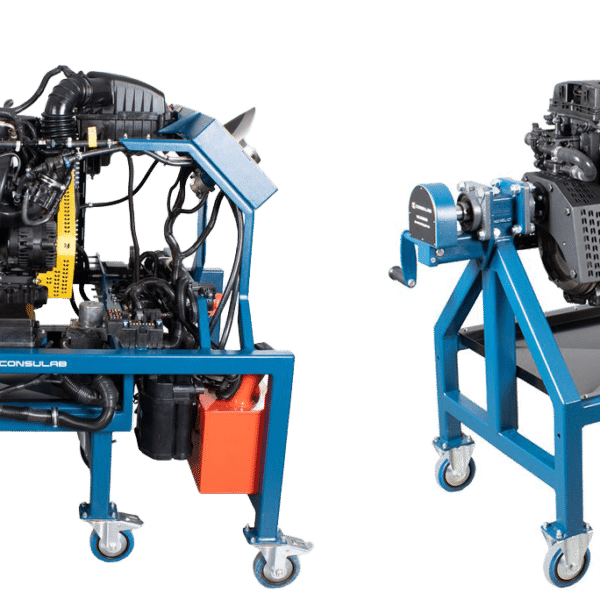

- Pump and/or motor installation procedures

- Pump and/or motor pre-start checks and adjustments

- Pump and/or motor start-up checks and adjustments

- How to set charge pressure relief valves on systems with and without hot oil shuttle valves

- How to set main pressure relief valves and pressure over-ride valves

- How to perform null adjustments on electronic displacement control valves

- How and where to check pump and motor case pressures

- How to perform mechanical adjustments on electronic and mechanical displacement control valves

- How to perform *diagnostic procedures on a hydrostatic transmission system

Options:

- Prime mover: Diesel drive

- Pumps: Any make or type currently available, e.g., Sauer Danfoss®, Rexroth®, Eaton®, Linde®, etc.

- Pump controls: Mechanical, hydraulic pilot

- Motors: High-speed/Low torque, fixed or variable displacement motors

- Hydraulic Implement and Articulated Steering System Module (FP-MF500-IS-TSE)