Description

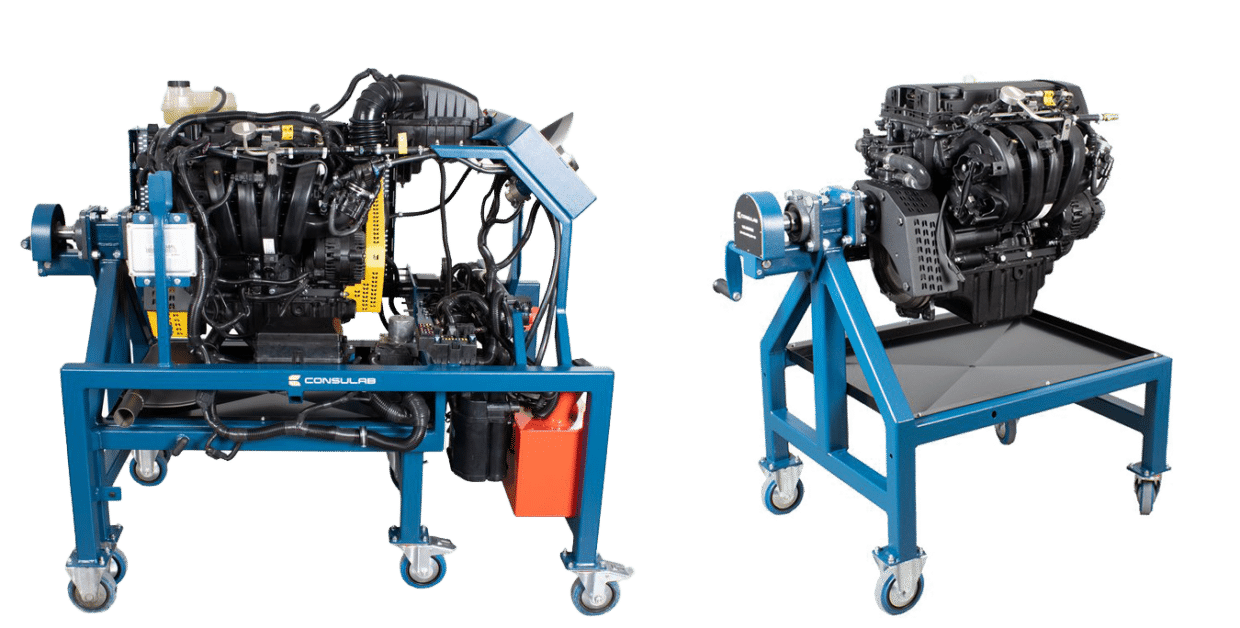

The Ecotec 1.8L engine on a swivel stand is designed for student instruction and practice covering engine mechanical inspection, disassembly, measurement and reassembly. The engine is securely mounted to a heavy duty rotating device to allow full 360 degree rotation. A steel mounting plate is used for engine mounting that allows full access for rear main seal and flywheel service. Each engine comes equipped with a transmission flywheel (manual or automatic). The engine starting station contains all components and systems necessary for the starting and running of the Ecotec 1.8L engine. All necessary engine systems connections are provided to allow live running of each swivel engine stand for verification of proper student assignment completion.

Educational Advantages

- Accessibility of engine components is enhanced by not having the requirement of a whole vehicle in the shop

- Ability to verify proper engine systems operation before and after engine repair assignments are completed

- Provides immediate feedback to students for confirmation of their workmanship and instruction completion

- Provides a single starting station that can be utilized with multiple swivel engine stands

- All rotating components are covered with safety shields or guards to prevent injuries

- Continuity of subject matter is provided by having students working on identical engines

- Multiple NATEF, Red Seal and Alberta tasks in the Engine Repair. Electrical/Electronics and Engine Performance areas can be instructed and practiced on these products

- Possibility to run the engine without starting it to demonstrate the mechanical pressure

- Easy access to the two crankcase seals

Application

- Starting Station : 2013-2015 Chevrolet Sonic

- Swivel Engine : GM Ecotec 1.8L LUW

Standard Equipment and Features

The swivel engine stand comes equipped with:

- Heavy Duty worm/ring gear rotating mechanism that allows slip free position- ing of engine throughout 360 degrees of rotation

- 31” x 24” 14 gauge stainless steel drip pan

- Full access to all internal and external engine components

- Leak proof quick-connect fittings for fuel injection supply and return lines

- OEM Starter and alternator

- OEM Port fuel injectors and throttle body assembly w/attached components

- OEM Engine Management Sensors including: MAP, ECT, TPS, O2S, CKP, CMP and MAT. No need to transfer components from one unit to another

- OEM Sequential Port Fuel injection

- Engine has Camshaft Variable Valve Timing

- OEM COP (Coil On Plug) Ignition system

- Heavy duty 2” x 2” x 1/8 ” square steel frame built specifically for each engine application

- 5” Phenol heavy duty casters (2-fixed and 2-swivel w/locks)

- Powder coated acrylic enamel finish

- Custom machined 5/8” steel engine mounting plate designed to allow full access to flywheel, crankshaft and rear main seal service procedures

- Equipped with a transmission flywheel (manual or automatic) for vibration free operation and starter system longevity

The starting station comes equipped with:

- Vehicle VIN number matching all included components (allows easy replacement of needed components from local suppliers)

- All OEM color matching wiring harnesses and electrical connectors necessary to operate the swivel stand engine

- Quick connect fuel lines for easy disassembly/assembly (Leak proof safety-type quick connect fittings for supply and return fuel lines)

- Fuel tank (22L – 5.8 gals) with OEM fuel cap suitable for EVAP testing

- Fuel tank has OEM fuel pump, sending unit and mounting design

- OEM functional EVAP system with test port

- OEM Catalytic converter

- OEM Radiator and hoses

- OEM Instrument cluster with gauges and indicators.

- OEM Anti-Theft system

- OEM COP (Coil-On-Plug) ignition system

- OBDII DLC (data link connecter) for scan tool hookup

- 12V battery

- Comes with only one OEM ignition key