Description

Electrical Troubleshooting

Electrical troubleshooting is one of the most important skills a technician can have in any industry – manufacturing, skilled trades, robotics, etc. – but it can be also be a complex and daunting task, especially for beginners or those lacking proper training. This can lead to costly mistakes and downtime for businesses and can slow a students’ training pathway.

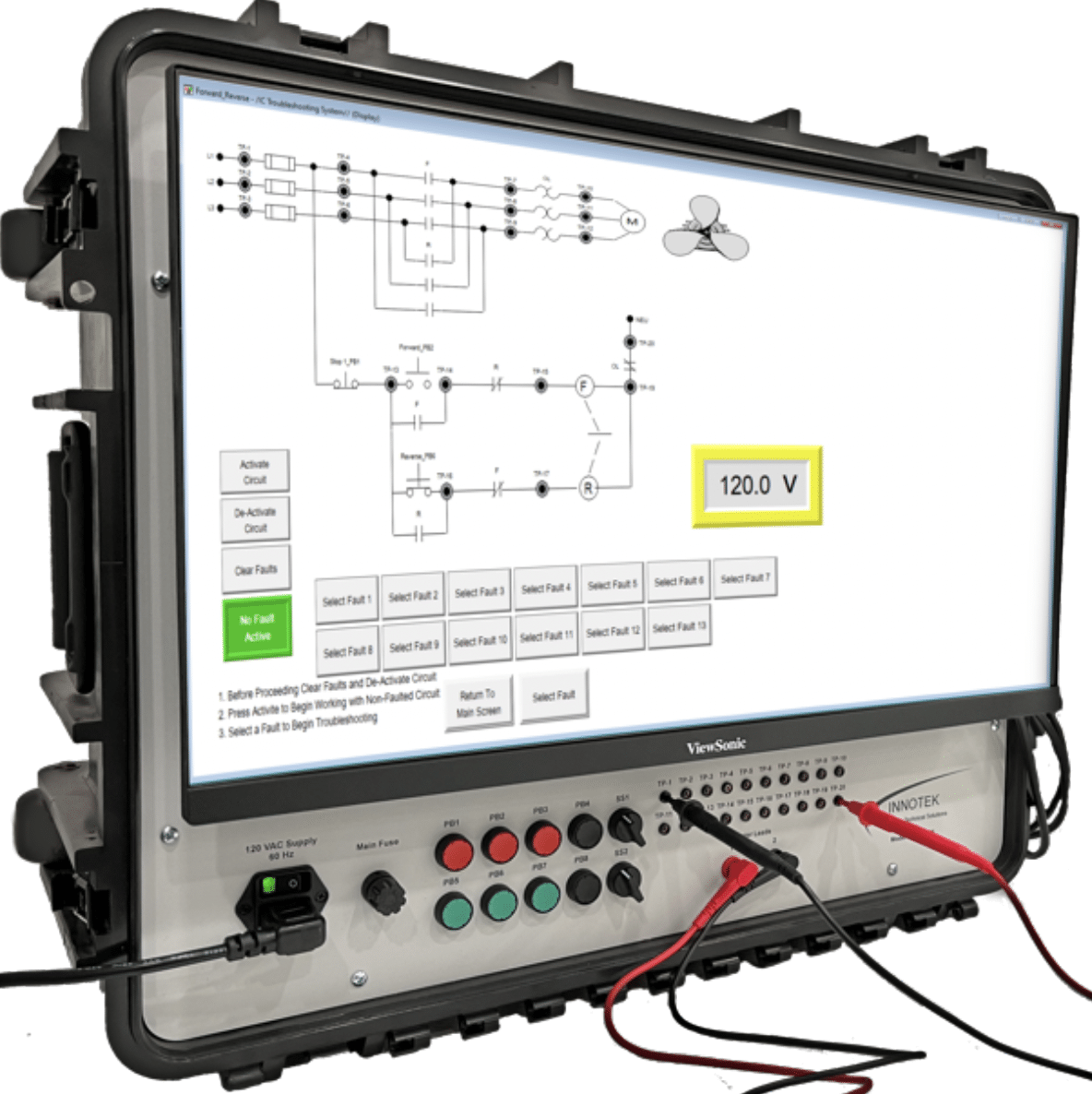

The Electrical Troubleshooting System offers a hands-on and portable training experience that is approachable and effective. Our system introduces the fundamentals of troubleshooting electrical circuits in a way that is practical and understandable, resulting in better troubleshooting skills, better understanding of foundation technologies, and better students.

The Training Process

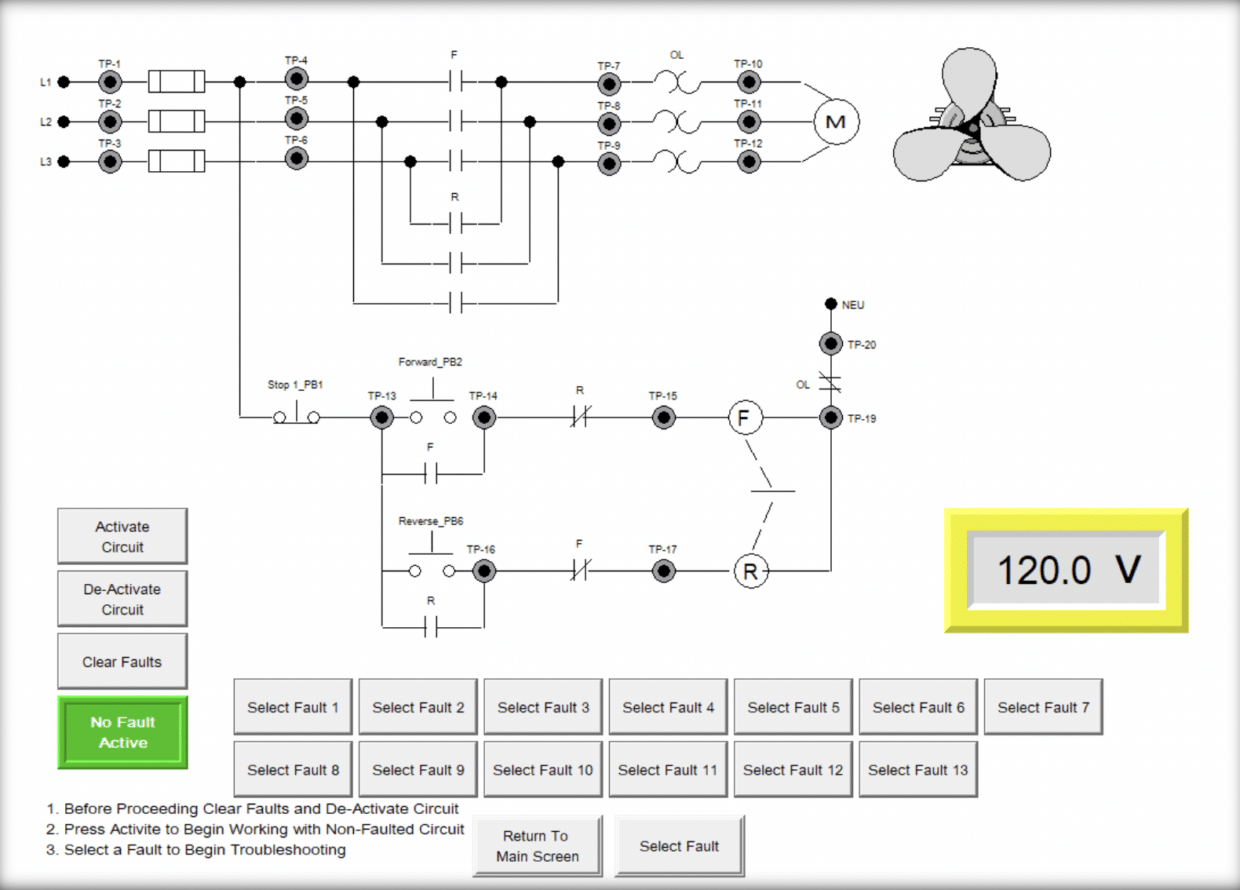

The custom software interface displays a control circuit for troubleshooting exercises. Test points are clearly identified and reference the actual test points on the front panel.

Participants can work with non-faulted circuits to gain familiarity, and then insert a fault from the interface. Actual test leads are used to measure values and determine if the circuit is faulty.

While in operation, the circuit is live and will animate during operation showing the condition of devices. Upon completion, the identified fault can be selected from a menu.

Training Focus Areas

- Basic Electricity

- Residential Circuits

- Industrial Motor Controls

- Programmable Controllers

- HVAC Controls

Specifications

- Hard-shell Portable Suitcase

- Casters and Removable Cover

- 120Vac Power Entry

- Main Fuse Protection

- Operator Control Devices

- (3) Red Pushbutton

- (3) Green Pushbuttons

- (2) Black Pushbuttons

- (2) 2-Position Selector •

- (20) Test Points

- (2) Voltmeter Lead Connections

- Integrated Monitor and PC with Preinstalled Software