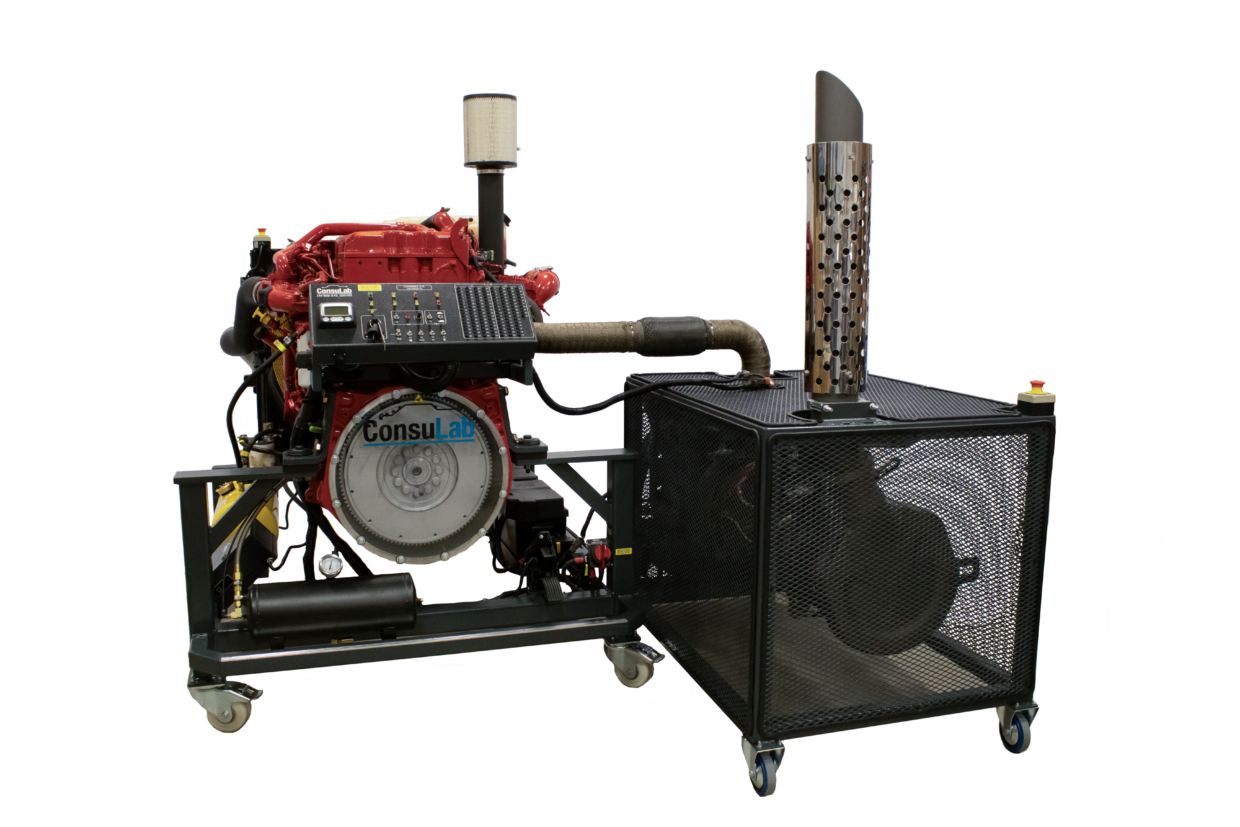

Description

Educational Advantages

- Includes Student activities

- Demonstration of major engine systems to groups of students without the access limitations of a complete vehicle

- Engine systems respond to inserted fauts with real world symptoms, OEM DTC’s and check engine light operation

- Functional DLC using SAE J1939 protocols

Application

- Cummins X15 EPA 2017 w/EGR, DPF, SCR

Standard Equipment and Features

- Recycled OEM In-line 6-cylinder, 4-stroke cycle diesel engine

- Interfaces with OEM diagnostic electronic service tools

- OEM Engine management system

- Air intake system with turbocharger and air filter

- Complete engine cooling system with fan, air-to-air, radiator, and fuel system

- OEM cold start system

- OEM ECM and wiring

- Master control panel with DLC (9-pin J1939 Deutsch connector) with:

- Keyed ignition system with two (2) keys and testing points

- Indicator lights

- Enable/disable switches

- PTO controls

- ECM breakout box with OEM pinout identification

- LOFA CANPlus display with J1939 parameters for installed components

- Complete intake and exhaust system with diesel particulate filter (DPF), maintenance indicators and muffler

- Engine lubrication system with filters

- Complete and operable fuse-protected electrical/electronic system (12 VDC)

- Fuel pedal

- 22L fuel tank with filters

- Heavy-duty batteries (2) with smart charger

- Battery cut-off switch

- Emergency stop buttons (2)

- Electronic programmable fault box with 12 faults with intermittent fault capability

- Safety guards on all rotating components in compliance with CSA regulation Z432-04 and on high temperature components

- DET frame:

- Heavy duty 3” (76.2 mm) powder enamel coated square tubular steel frame

- Four (4) removable heavy-duty casters, two (2) locking swivel, two (2) fixed

Functional Aftertreatment Systems

- DOC (Diesel Oxidation Catalyst)

- EGR (Exhaust Gas Recirculation)

- DPF (Diesel Particulate Filter)

- SCR (Selective Catalytic Reduction)