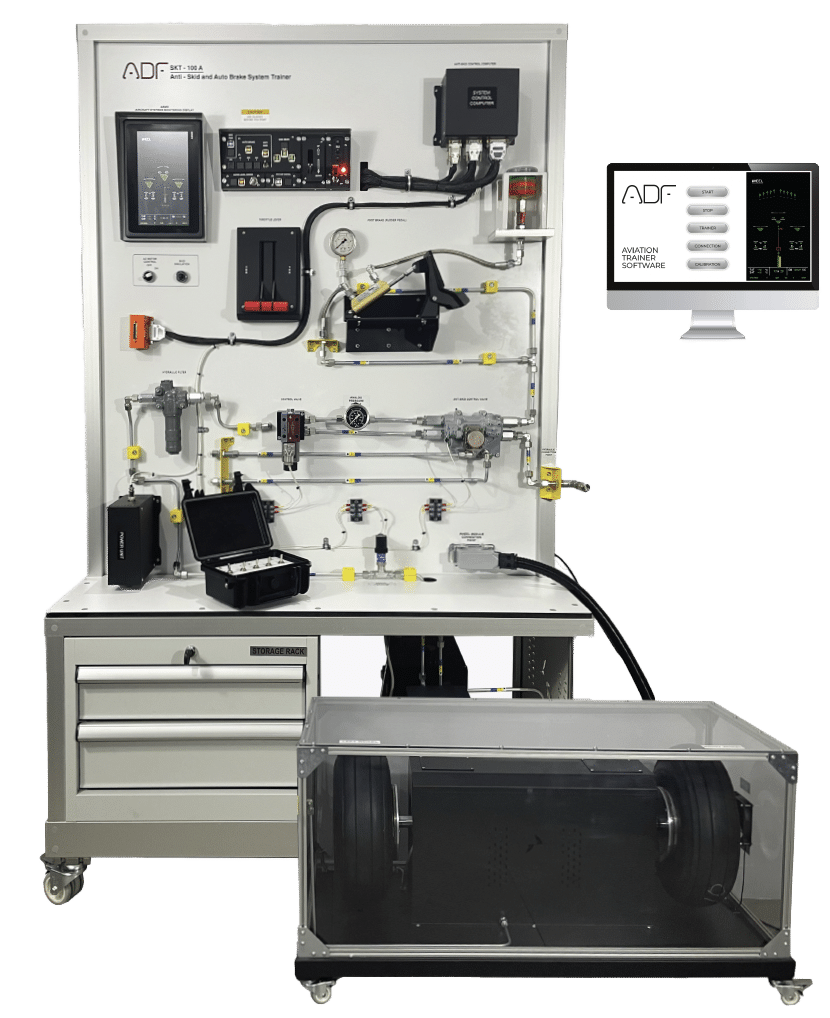

Description

Features

• Understanding fundamentals of aircraft auto-brake/anti-skid and its

components.

• Anti-skid and auto-brake system able to work together and independently

• Non operations of auto-brake scenario are implemented

• Operations of auto-brake scenario are implemented

• Take off scenario is implemented

• Landing scenario is implemented

• Auto-brake scenarios is implemented

• Rejected take off scenario is implemented

• Some of Trainer Functions

• Auto-brake function

• Anti-skid function

• Food brake function

• Rejected take off function

• WOW switch function

• Brake fan function

• Pumps fault function

• ECAM functions

• Single chime functions

• Master caution functions

• Master warning functions

Components

• Control Panel

• Aural warning horn

• Master warning resettable illuminated pushbutton

• Master caution resettable illuminated pushbutton

• Auto brake – low illuminated pushbutton

• Auto brake – medium illuminated pushbutton

• Auto brake – max illuminated pushbutton

• Auto brake – RTO illuminated pushbutton

• Auto brake – disarm instrument

• Anti-skid INOP instrument

• Brake fan control illuminated pushbutton

• Brake fan hot instrument

• Nose landing gear instrument light

• Left wing landing gear instrument light

• Right wing gear instrument light

• Landing gear unlock instrument light

• Hydraulic pump control illuminated pushbutton

• Hydraulic pump fault instrument light

• Three (3) aircraft circuit breaker

• Guarded master power switch

• Master power lamp

• Lockable Landing gear control lever

• AC engine on/off switch

• Air/ground switch

• Skid simulation panel

Training System Processes

• Take-off process

• Landing process

• Anti-skid fault process

• System test process

Training System Cases

• Brake hot

• Park brake fault

• Hydraulic fault

• Auto brake fault

• Instructor’s panel for Fault Insertion

• The system mounted on a metal/aluminum mobile stand.

• Metal/aluminum frame with 4 wheels. 2 of 4 wheels are lockable.

• Training video for teachers

• Delivered fully assembled tested and ready to operate

• Colored Ultraviolet printing method on aluminum composite panel• 10” inch screen (like EICAS or ECAM)

• Landing gear position

• Landing door position

• Numeric pressure value

• Sensor’s status

• Anti-Skid/Auto-Brake position status

• Numaric Simulated air speed value

• Electronic Control Box (Antiskid Control Computer)

• Antiskid Valve

• TQ – throttle quadrant

• Electrically Driven Hydraulic Pump

• Hydraulics Filter

• Hydraulic Fluid Reservoir

• Hydraulics tank Drain Valve

• Check valve

• Brake fan

• 0-100 bar Hydraulic System analog pressure gauge

• 0-100 bar Hydraulic System Pressure sensor

• Aircraft landing gear module

• Two(2) pieces Aircraft Tire

• Two(2) pieces Aircraft Wheel

• Two(2) pieces Aircraft Brake system

• Two(2) pieces AC motor for turning the wheels

• Plexiglass cover

• Aircraft foot Brake Pedal

• Aircraft foot Brake master cylinder

• Brake microswitch

• Two(2) pieces AC motor for turning the wheels

• Two(2) pieces AC motor driver

• Fault & instructor port

• Lockable Fault & instructor box

Documentation and Power Specs

• User’s Manual

• Study Guide

• Instructor’s Guide

• Components Diagrams

• Electrical box

• Residual current device

• Emergency Button

• Energy Signal Lamp

• 110 VAC 60 Hz or 220-240 VAC 50 Hz