Description

Features

- Understanding fundamentals of aircraft Cabin Pressurization and its components.

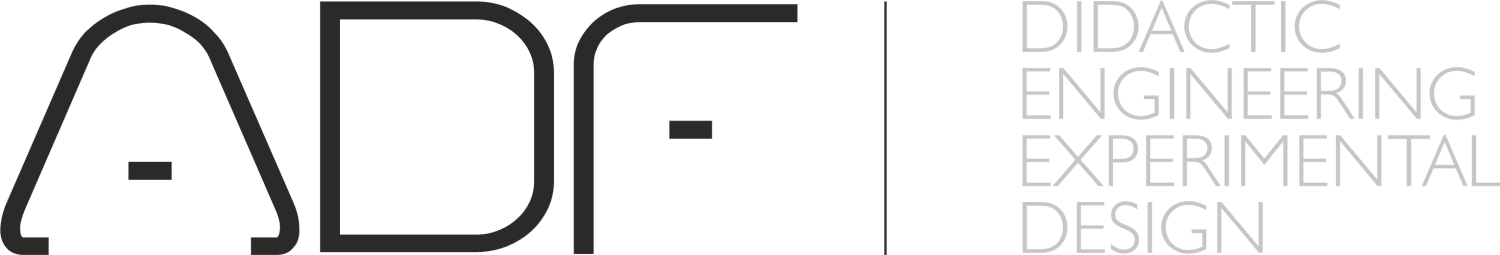

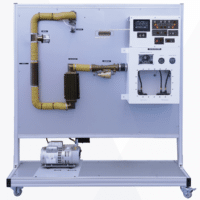

- The training system is functional and configured like a typical aircraft Cabin Pressurization system.

- The trainer include the following panels that will work functionally.

- Aircraft Cabin Pressurization panel

- Aircraft air condition panel

- Aircraft auto-pilot panel

- Test panel

- Master power panel

- Master caution panel

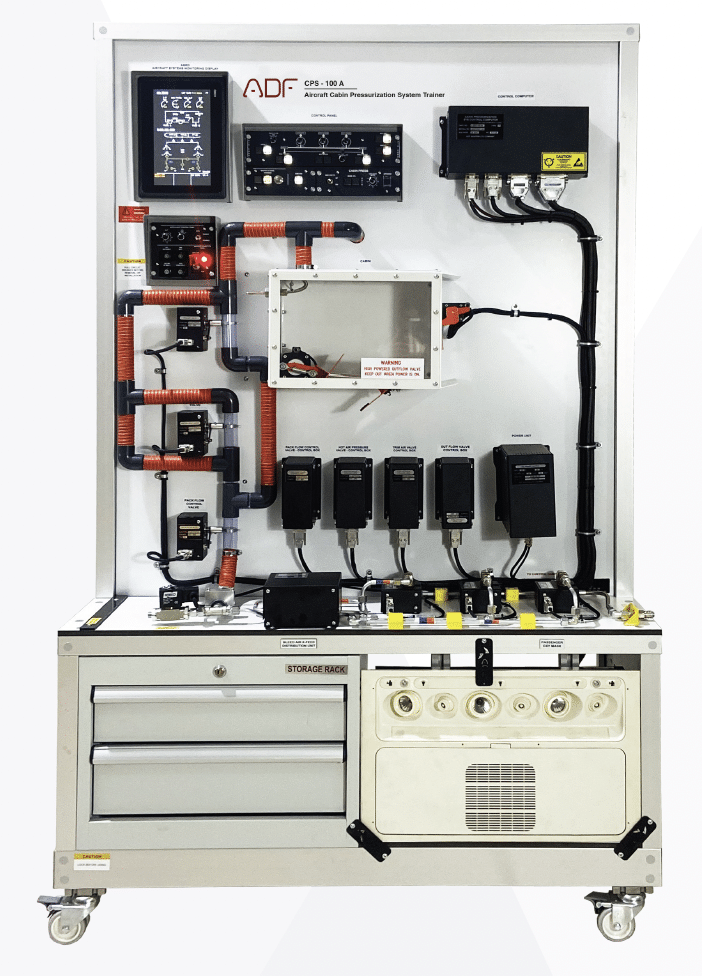

- Two transparent cabin in the training set to simulate the interior of the cabin.

- 2 outflow valves, 1 negative pressure safety valve, and positive pressure safety valve (as a substitution) are in the transparent cabin.

- Out Flow Valves are engine controlled.

- The valves in the cabin pressurization system operate automatically during the take off and landing.

- Cabin pressurization valves are both controlled manually and automatically.

- The trainer is able to perform full automatic take off and landing.

- Indicators, panels and valves work simultaneously in landing and take-off simulations.

- Take off and landing simulations are controlled from the autopilot panel.

- Vertica speed and altitude are determined and selected during take-off and landing.

- Valve failures are easily observed on gauges and panels.

- PACK, BLEED, PACK FLOW and TEMPERATURE selections are made at the air condition panel.

- LDG elevation, MODE SELECT, MAN V/S CONTROL and DITCHING are done at the cabin pressurization.

- The selections made in the panels are visible on the screen.

- Wirings on the trainer are connected via terminals.

- Wires should have clear identification labels for each wire.

- All wires should be coded and labeled for troubleshooting.

- Instructor’s panel for Fault Insertion

- The system mounted on a metal/aluminum mobile stand.

- Metal/aluminum frame with 4 wheels. 2 of 4 wheels are lockable.

- Training video for teachers

- Delivered fully assembled tested and ready to operate

- Colored Ultraviolet printing method on aluminum composite panel

Components

- Heat Exchanger

- Muffler

- Relief Valve

- Shut-Off Valve

- Vacuum Pump

- System Indicators

- PSU( Passenger Service Unit)

- 10 inch Lower ECAM

- Vertical speed indicator

- Altimeter indicator

- Cabin Altimeter

- Cabin pressure

- Air pressure

- Differential pressure

- Status area

- Flow status

- Pack flow status

- Bleed status

- Auto pilot status

- Pressurization mode

- Temp

- Air/ground

- Min 2 Outflow valve

- Min 2 outflow control computers

- Aircraft Cabin Pressurization panel

- Man V/S Control Switch

Component Technical Specs

- NAV/COMM Transceiver

- 200-channel NAV receiver

- Built-in VOR Converter

- Maksimum 25 kHz channel spacing

- Frequency(COM) 118.000 to 136.975

- Nav frequency 108.00 MHz to 117.95 MHz in 50 kHz spacing

- VOR/LOC converter

- Input voltage 28 VDC

- Built-in VOR/Localizer converter

- flip-flop frequencies

- Volume control

- Frequency memory and recall

- Display

- Frequency stability: ±0.0015%

- Original installation manual.