Diesel and Heavy Truck

Toolkit’s Diesel and Heavy Truck Training Systems give students real-world access to the technologies and systems found in their future careers/industries, along with practical and realistic training activities and exercises. Toolkit is proud to prepare the next generation of Heavy Truck and Diesel technicians and mechanics for successful careers.

Job Outlook

Careers in diesel and heavy truck fields have been growing steadily and are forecasted to continuing growing in demand through 2030. Diesel service technicians and mechanics (also known as diesel technicians) inspect, repair, or overhaul buses and trucks, or maintain and repair any type of diesel engine.

Because of their efficiency and durability, diesel engines have become the standard in powering trucks and buses. Other heavy vehicles and mobile equipment are commonly powered with Diesel Engines, including bulldozers, cranes, and common construction vehicles.

Job Duties

Diesel and Heavy Truck service technicians and mechanics wear many hats, but working on diesel engines and hydraulic systems is a common job duty. Diesel technicians make major and minor engine repairs, and work on a vehicle’s electrical and exhaust systems to comply with pollution regulations.

Engine maintenance and repair is becoming more complex as engines and other components use more electronic systems to control their operation. For example, fuel injection and engine timing systems rely on microprocessors to maximize fuel efficiency and minimize harmful emissions. In most shops, workers often use hand-held or laptop computers to diagnose problems and adjust engine functions.

Mechanics and technicians also use a variety of power and machine tools, such as pneumatic wrenches, lathes, grinding machines, and welding equipment. Hand tools, including pliers, sockets and ratchets, and screwdrivers, are commonly used.

Employers typically provide expensive power tools and computerized equipment, but workers generally acquire their own hand tools over time.

TOOLKIT Diesel and Heavy Truck

Changing technologies and increasing job roles requires schools to reevaluate their Diesel and Heavy Truck labs to ensure students are receiving up-to-date training aligned with industry needs. Toolkit is here to help schools provide up-to-date and exciting training in Diesel and Heavy Truck technologies with unparalleled training solutions for diesel, diesel hydraulics, Ag Mechanics, and heavy truck simulators.

Showing all 3 results

-

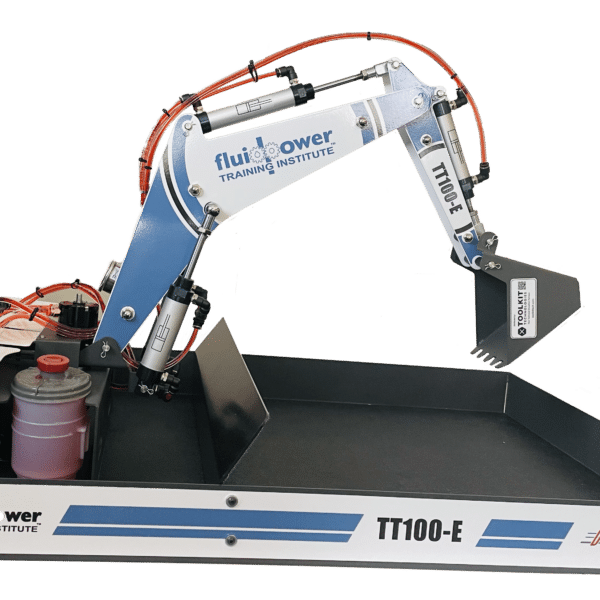

Tabletop Hydraulic Excavator Kit

Our brand new tabletop hydraulics excavator kit brings real-world hydraulic principles to life for students to explore hydraulics in an engaging and project-based approach!

Build your excavator and learn the basic hydraulic concepts necessary for industrial skills in agriculture, industrial maintenance, heavy truck, and manufacturing careers.

Build, Create, Dig, and Learn!

-

Werk Wagon Portable Training Center

Toolkit is proud to offer schools and training facilities a completely customizable and mobile solution for workforce training, STEM education, CTE skills development with our new WERK WAGON portable training centers!

Completely customizable, modular and portable training in a whole new way. Our Werk Wagon is perfect for schools looking to bring their training and expertise into the community, or share resources between schools, or with physical space limitations that require larger bond and/or construction money. Toolkit’s Werk Wagons are mobile, portable Workforce Training Centers and simply amazing!

Customizable sizes, dimensions, and physical features allow these mobile training centers to fit perfectly to your needs and to focus on your needed training areas.

-

MF102 Hydraulics Training System

TOOLKIT is proud to offer the flagship hydraulics training system from the Fluid Power Training Institute (MF102-H), which includes 40-hours of possible training in hydraulics.

From foundational hydraulics skills and safety to advanced hydraulic concepts, this system features unparalleled design, craftsmanship, ergonomics, and robustness perfect for any classroom or training program. Featuring all industrial components, this system is made and manufactured in the USA.

Single-Sided or Double-Sided