Ag Mechanics

Toolkit is proud to offer the very best Ag Mechanics Training Systems for schools and workforce development programs.

The heartbeat of America’s farmland, nothing would be possible in modern agriculture practices with machinery and technicians who know how to operate, fix, repair, and maintain this machinery.

Ag Mechanics Job Outlook

Ag Mechanics refers to the people and technology that helps farmers and ranchers maintain their lands – from building or troubleshooting hydraulic circuits to welding or diagnosing/repairing a diesel engine.

Known as Agricultural Equipment Mechanic, Combine Mechanic, Dairy Equipment Mechanic, Dairy Equipment Repairer, Harvester Mechanic, Irrigation Equipment Mechanic, Milking Machine Mechanic, or Tractor Mechanic.

The overall job outlook for Farm Equipment Mechanic or Service Technician careers has been positive since 2004. Vacancies for this career have increased by 16.09 percent nationwide in that time, with an average growth of 1.01 percent per year. Demand for Farm Equipment Mechanics and Service Technicians is expected to go up, with an expected 5,580 new jobs filled by 2029. This represents an annual increase of 1.74 percent over the next few years

Toolkit is here to bring hands-on and exciting Ag Mechanics Training Systems to CTE classrooms.

Showing 1–12 of 17 results

-

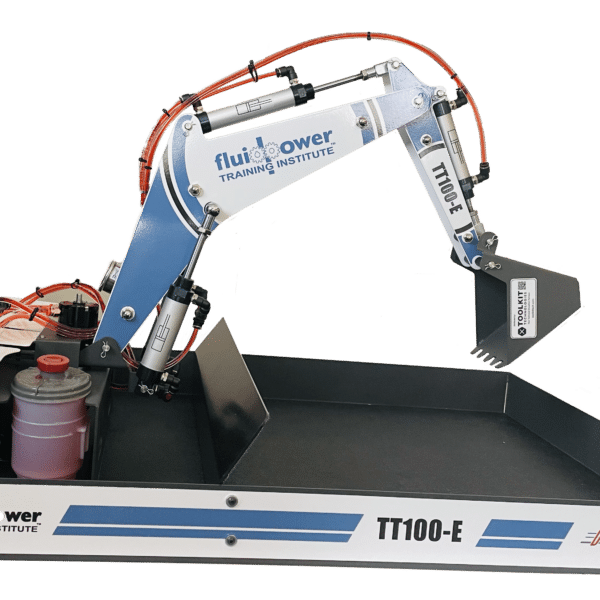

Tabletop Hydraulic Excavator Kit

Our brand new tabletop hydraulics excavator kit brings real-world hydraulic principles to life for students to explore hydraulics in an engaging and project-based approach!

Build your excavator and learn the basic hydraulic concepts necessary for industrial skills in agriculture, industrial maintenance, heavy truck, and manufacturing careers.

Build, Create, Dig, and Learn!

-

Tenstar Heavy Equipment Operator Simulator

The most exciting and immersive driving simulator available to students for real-world training on real equipment and machines.

Our unique Virtual Reality Simulator offers the unique ability to combine several machine types all on the same platform for varied and robust training capabilities! Train on over 27 industrial equipment types and machines all on the same simulator!

With our modular design, you can always adapt the simulator platform to create your optimal solution by combining professional components from the industry – steering wheel, joysticks, pedals, control systems, screens, VR headsets, etc.

Each machine education driving simulator has a set of carefully developed exercises, optimized to train the students in areas of maintenance, driving, maneuvering, safety and special handling.

-

Series-Parallel Circuit Trainer

The Modular Magnetic Training System – MagMat – is a cutting-edge teaching tool designed to help students grasp fundamental electrical concepts and vehicle-specific circuits. Ideal for classroom settings, this system combines hands-on learning with real-world applications, making complex electrical theory accessible and engaging. Learn electrical fundamentals and take your circuit directly to the car, vehicle, tractor, and beyond!

Why Choose the MagMat?

- Interactive and Engaging: Leverage magnetic surfaces like classroom whiteboards to create dynamic and hands-on learning experiences.

- Practical Diagnostics: Teach students how to design circuits, introduce or remove faults like high resistance and open circuits, and understand real-time diagnostics for practical problem-solving.

Key Features of the MagMat:

- Magnetic Circuit Components: Includes printed circuit boards with integrated resistors, LEDs, switches, and wiring diagrams for seamless learning and experimentation.

- Versatile Nodes: Wires, LEDs, switches, and splices allow students to create, modify, and troubleshoot various circuit configurations with ease.

Empower your students with the Magnetic Mat Electrical Training System, the ultimate classroom solution for mastering electrical fundamentals and diagnostics with hands-on practice.

-

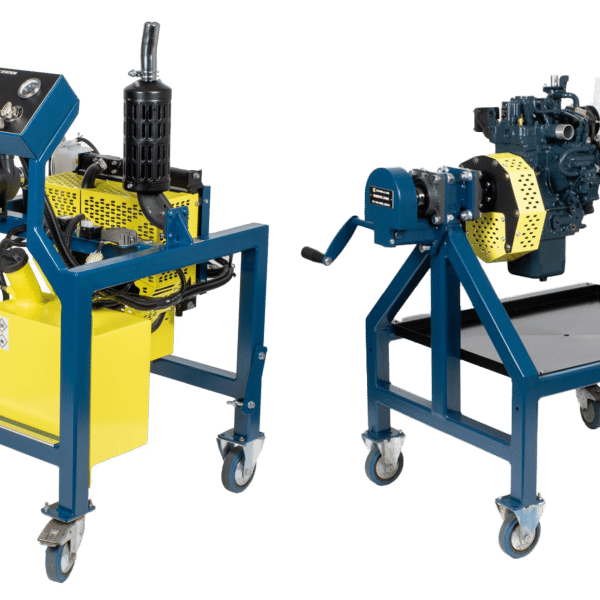

Diesel Engine Repair Trainer 2-Cylinder Mechanical Injection

The ConsuLab HV-145S Diesel Repair Trainer (2-cyl mechanical injection) is a complete running diesel engine for your classroom. A teardown station for teaching engine mechanical, with low-cost consumables, small package size and brand-new components. Teach the fundamentals of diesel engines, mechanical fuel injection systems, injectors, pumps, component identification all on this Kubota 2-cylinder engine from ConsuLab.

- Engine may be run prior to disassembly and after reassembly.

- Functional fuel control lever.

- Bell housing plate allows access to crank pulley bolts and rear main oil seal

- Robust connectors between the starting station and swivel for all connection points.

- Flat-faced leak-less fuel line connections between the two units.

-

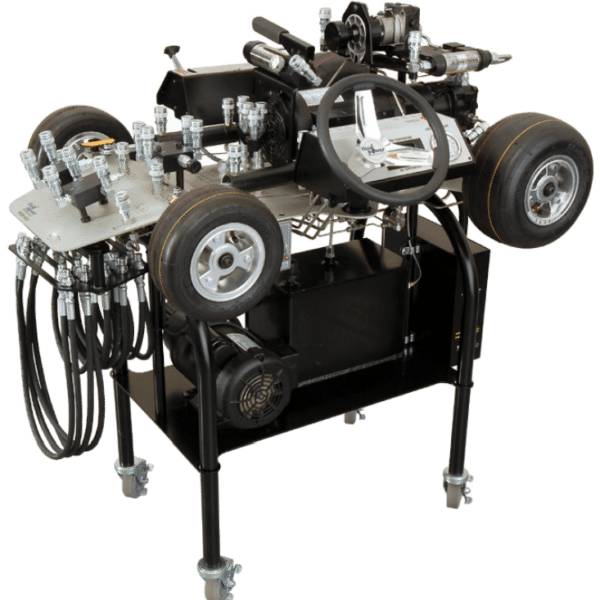

Hydrostatic Transmission – Implement and Steering

The FP-MF500-IS-TSE Hydrostatic Transmission Trainer features the exact transmission found in the vast majority of skid-steer loaders, mini-backhoes, and numerous other mobile and industrial machines. This trainer is provided with hydraulic steering and implement, and is available as a diesel engine-driven simulator or an electric motor-driven simulator. The trainer is equipped with a state-of-the-art, dual-drive, hydrostatic transmission system. The dual-pumps are electronically controlled with independent joysticks – just like the actual vehicle. The state-of the-art, electronically-controlled, wheel load system is designed to simulate any driving conditions, regardless of severity, that a typical hydrostatic drive might experience.

-

MF102 Hydraulics Training System

TOOLKIT is proud to offer the flagship hydraulics training system from the Fluid Power Training Institute (MF102-H), which includes 40-hours of possible training in hydraulics.

From foundational hydraulics skills and safety to advanced hydraulic concepts, this system features unparalleled design, craftsmanship, ergonomics, and robustness perfect for any classroom or training program. Featuring all industrial components, this system is made and manufactured in the USA.

Single-Sided or Double-Sided

-

MF102 Hydraulics Trainer + Troubleshooting

We are proud to bring this incredible hydraulics training system to schools whereby students can get invaluable hands-on training in the fundamentals of Hydraulics, Hydraulics Safety, Advanced Hydraulics, and now the added training benefit of Troubleshooting capabilities.

The MF102-H-TS includes 40-hours of possible training on the base model PLUS an additional 40-hours of training in troubleshooting possible. Unparalleled in terms of craftsmanship and curriculum, this trainer is proudly designed and built in the USA.

Available Single-Sided or Double-Sided

-

MF102 Hydraulics Trainer with Troubleshooting and Touchscreen

The best hydraulics training system on the market keeps getting better! Fluid Power Training Institute’s MF102-H-TSE Hydraulics Training System with Troubleshooting now includes a built-in Touchscreen Monitor and PC for practical lab activities, troubleshooting, and student tracking!

Students get in-depth, hands-on training in the fundamentals of hydraulics, advanced hydraulics, troubleshooting, safety, and more with over 40 hours of curriculum in the base system, additional 40 hours in troubleshooting, and more with additional options.

With the built-in monitor, instructors can automatically track student activity to determine whether they truly understand how to effectively diagnose hydraulics problems or are just “replacing parts” at random!

Available in single-sided or double-sided systems.

-

Hydrostatic Transmission with Hydraulic Steering

The Hydrostatic Transmission with Hydraulic Steering trainer is a “lean, mean troubleshooting teaching machine.”Almost every hydraulic component can “fail” at the flick of a switch for your students to master hydraulics troubleshooting skills.

The MF300 is an extremely versatile 2-in-1 training system designed for teaching and learning hydraulic steering and hydrostatic transmissions.

This is a great option for people who need to teach the basic concepts behind hydrostatic transmission and steering systems, but are short on funds and/or space. You can fault everything in the steering system, but only the pump can be faulted on the transmission end of the trainer.

-

Hydrostatic Transmission + Driving Simulator

The MF500-HT-TSE is an instructor’s “dream-come-true” with respect to teaching state-of-the-art, electronically-controlled hydrostatic transmission systems – hands-on. It can even be driven as if it were on a construction site, in real-time!

Driving a skid-steer loader around a construction site and operating the MF500-HT-TSE in the lab amounts to the same thing – without the hazards!

Designed for instructors who want to teach hydrostatic transmission and steering systems with the same components found in popular front-end loaders but without the safety hazards and physical limitations of operating a loaded, faulty skidsteer in a shop full of students.

Teach basic concepts to advanced applications + troubleshooting in a classroom-friendly manner where students can gather around to see real-time symptoms of faults as you drive the simulator through a variety of scenarios.

-

Pump Cavitation Trainer

The FP-MF200-CAV simulator is the most advanced trainer in the world for teaching students everything they need to know about cavitation, its common causes, and its devastating effect on a hydraulic system.

Much thought went into the design of this training masterpiece. The transparent reservoir, transparent pump suction line, and transparent pump outlet port transmission line are backlit to enhance the stunning visual impact this simulator offers.

Students learn:

- How the inlet side of a hydraulic pump works

- Why it is critical to establish a “trend” for pump inlet restriction

- How and why cavitation occurs

- Safe and effective diagnostic procedures for determining the root-cause of cavitation

-

Hydraulic Cylinder Training System

The MF400-HCTS is designed to help instructors teach and students learn how to safely and correctly perform the following skills:

• Overhaul a hydraulic cylinder.

• Identify and use the tools needed to overhaul a hydraulic cylinder.

• Inspect the components in a hydraulic cylinder to determine the root cause of a failure.

• Replace piston and gland seals.

• Test a hydraulic cylinder.

• Air bleed a hydraulic cylinder.