Process Control

Showing all 3 results

-

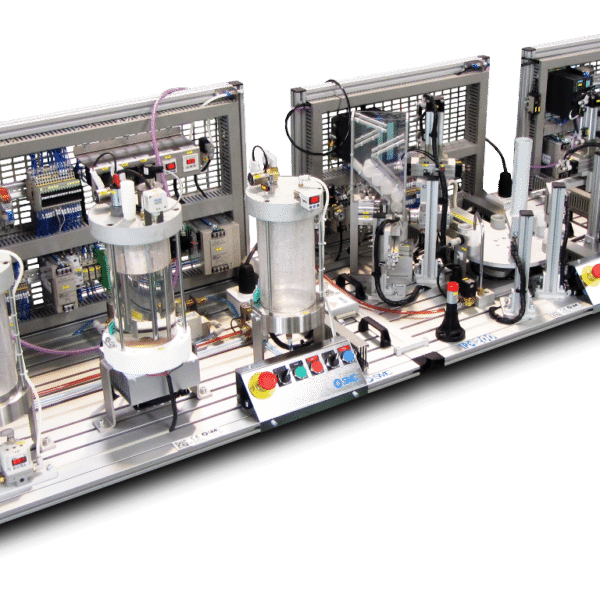

SMC Automated Process Control Training System

The IPC-200 is SMC’s unique training solution specific to automation and process control. Commonly used for training in the food & beverage production and processing industries as well as pharmaceutical industry, the IPC-200 brings real-world industrial skills and technologies to students’ fingertips with an exciting and project-based tabletop training system.

A fully modular and flexible automate process control system, the IPC-200 is comprised of three modules which can work individually or as a complete process line. Various configurations can be created to adapt the IPC-200 equipment to our users different requirements and budgets.

IPC-200 emulates a liquid production and bottling plant and includes the technologies used in a continuous process industry, such as pneumatics, electric motors, sensors, continuous processes, programmable controllers, industrial communications, etc.

It is built entirely from industrial materials so that student works with the same elements found in the working environment.

-

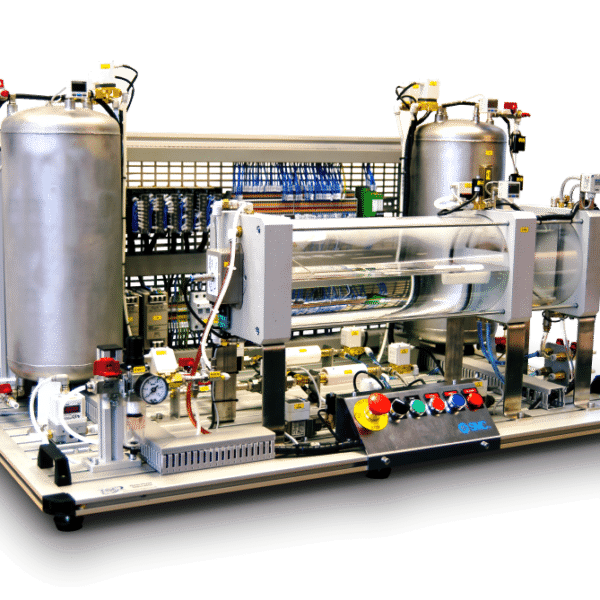

SMC Three-Phase Separator

The new 3-Phase Separator Training System from SMC emulates the industrial separation process of the oil, gas and water obtained from oil wells during the oil production process. The process is performed with all gaseous and liquid components in a pressurized container.

A Three Phase Separator for oil production is a large container designed to separate the fluids obtained from the well into its individual constituent components: oil, gas and water. These types of separators are based on the principle that the three components have different densities. This allows separating them when they move slowly, the gas in the upper part, the water in the bottom and the oil in the middle.

SMC’s new 3-Phase Separator Training System includes all hardware, software, and learning content for effective training in process control and three-phase separation concepts.

-

SMCTwin-400 Digital Twin Software

We are thrilled to bring the first Digital Twin training software to schools across the globe with SMC’s revolutionary Digital Twin-400 software.

SMCTwin-400 is an online, one-for-one emulation platform where students will be able to develop and control digital twin models. All models operate and behave in the exact manner in which they would in the real world, giving students a never-before-seen lens to view automation and industry.

This true Industry 4.0 software provides students with the ability to access virtual replicas of real SMC training equipment and industrial components, allowing them to safely experience industrial technologies and processes, monitor all of the system’s electrical and pneumatic values, program and create various PLC/HMI programs, and witness the results in real time!