Fluid Power

Showing all 4 results

-

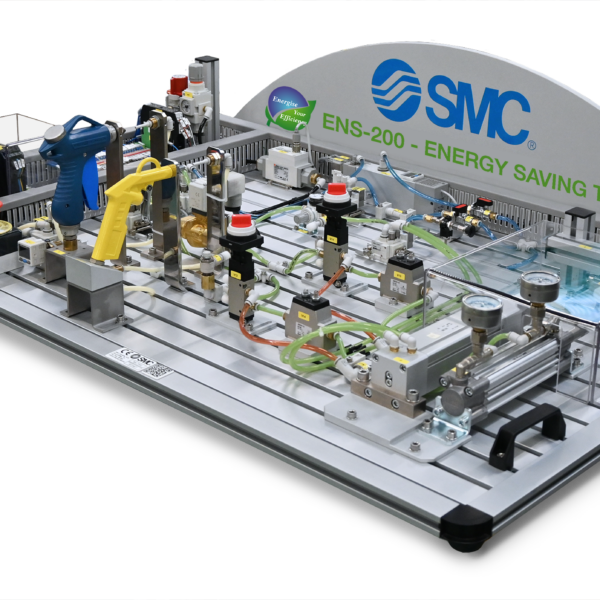

SMC Air Energy Savings Trainer

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed a state-of-the-art training system for teaching students about Sustainability, Energy Efficiency, Green Technologies, and Air Leakage.

The ENS-200 integrates a series of applications (vacuum, actuators and blowing) aimed at getting technicians to understand and implement the proper procedures and standards associated with energy saving in compressed air installations.

Modern Manufacturing needs to be green and companies are adopting these green energy conservation technologies and techniques, so let’s train students to be prepared.

The ENS-200 teaches you how to detect possible excessive consumption and suggest actions to prevent it. Users will analyze different scenarios through a series of guided activities. Each experiment shows how much has been saved, both as a percentage and in the chosen currency.

-

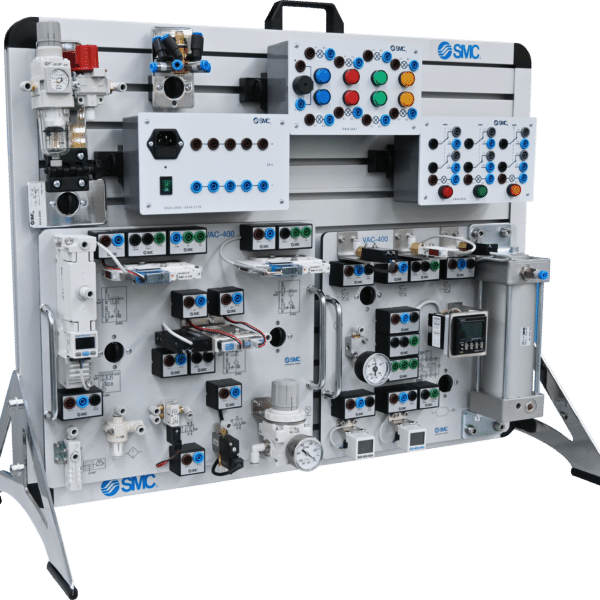

SMC Vacuum Technology Training System

SMC, the worldwide leading manufacturer of Pneumatic Components and Technologies, has developed a training system specifically for hands-on skills development in Vacuum Technology. Featuring the most commonly found vacuum technologies found in industrial companies like Intel, Dell, Apple, Samsung, Toyota, and more, the VAC-400 is the training system needed for skills development training in vacuum technologies.

-

TAP Semiconductor Training Platform

Our TAP Semiconductor Learning Platform transforms Career and Technical Education with an immersive and robust learning environment for the semiconductor industry and industrial automation.

TAP delivers cutting-edge online courses and immersive simulations tailored for career and technical education (CTE) programs, as well as tailored training materials for technicians in the semiconductor industry. Designed in collaboration with leading advanced manufacturers, TAP offers a robust curriculum covering critical skills in the semiconductor industry, such as pneumatics, electrical fundamentals, and multi-axis robotics. The platform features in-simulation quizzes, real-time audio guidance, VR assessments, and comprehensive data dashboards to track student progress. With over 51 years of combined industry expertise, TAP equips educators with tools to prepare students for high-demand technical careers, ensuring graduates are job-ready and productive from day one.Key Benefits for Educators:

- Enhance learning with hands-on, virtual reality training modules.

- Access industry-aligned content for skills in manufacturing and automation.

- Empower students with real-world technical skills.

-

SMCTwin-400 Digital Twin Software

We are thrilled to bring the first Digital Twin training software to schools across the globe with SMC’s revolutionary Digital Twin-400 software.

SMCTwin-400 is an online, one-for-one emulation platform where students will be able to develop and control digital twin models. All models operate and behave in the exact manner in which they would in the real world, giving students a never-before-seen lens to view automation and industry.

This true Industry 4.0 software provides students with the ability to access virtual replicas of real SMC training equipment and industrial components, allowing them to safely experience industrial technologies and processes, monitor all of the system’s electrical and pneumatic values, program and create various PLC/HMI programs, and witness the results in real time!