Does Your Automotive Program Include EV Training? If Not, You’re Falling Behind.

Hybrid and Electric Vehicles (EV) have proven to be the future, but most underestimate just how close that future is and how unprepared the workforce currently is. It’s hard to separate the EV movement from the media buzz around the high-flying Tesla brand and the bravado of its CEO, Elon Musk, but let’s look at the numbers.

Key Drivers of the EV-Hybrid Movement

The shift from traditional combustion engine vehicles to EV is driven by three interrelated factors: Consumer Demand, Product Selection, and Infrastructure. Let’s take a moment to look at each individually.

Demand

Tesla can be called many things, but it’s difficult to deny that the car manufacturer has made electric vehicles “sexy” to the general consumer. With large tablet displays, autopilot capabilities, wireless updates, and consumer perks like “Sentry mode,” “Dog mode,” and falcon-wing doors, Tesla proved electric vehicles don’t have to be a compromise. According to EY Insights

[https://www.ey.com/en_us/emobility], 41% of consumers globally are now willing to purchase an electric vehicle, and EV sales are projected to outpace traditional combustion more than a decade earlier than expected.

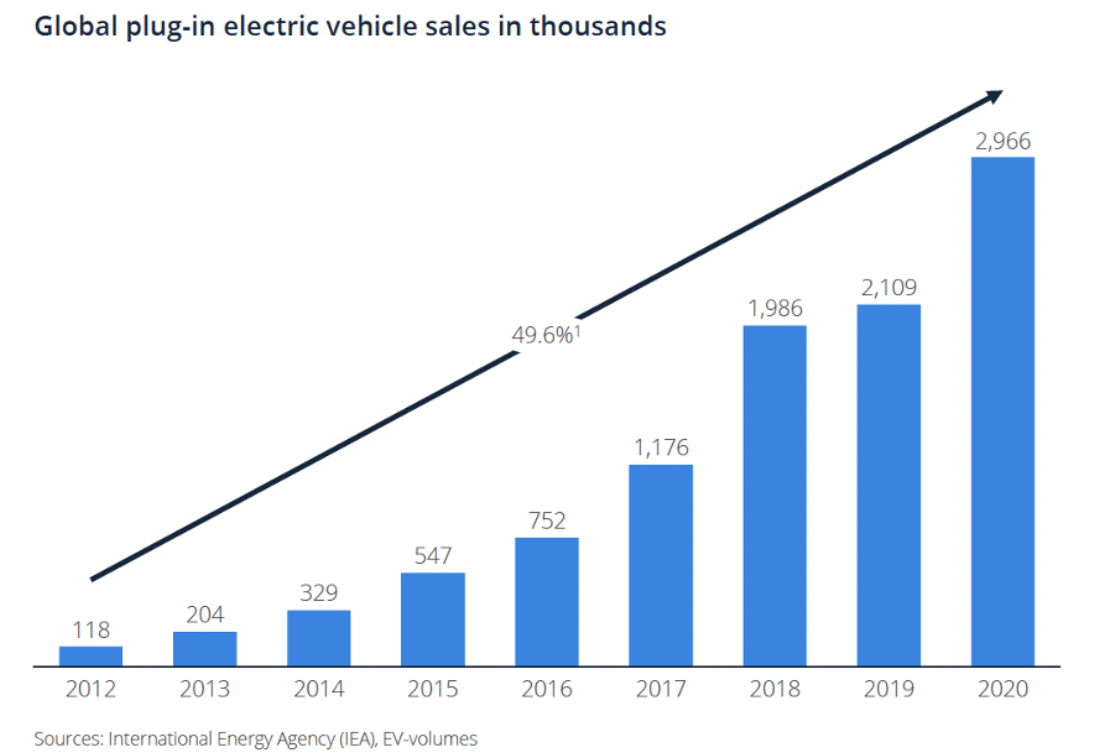

Plug-In Electric Vehicle Sales

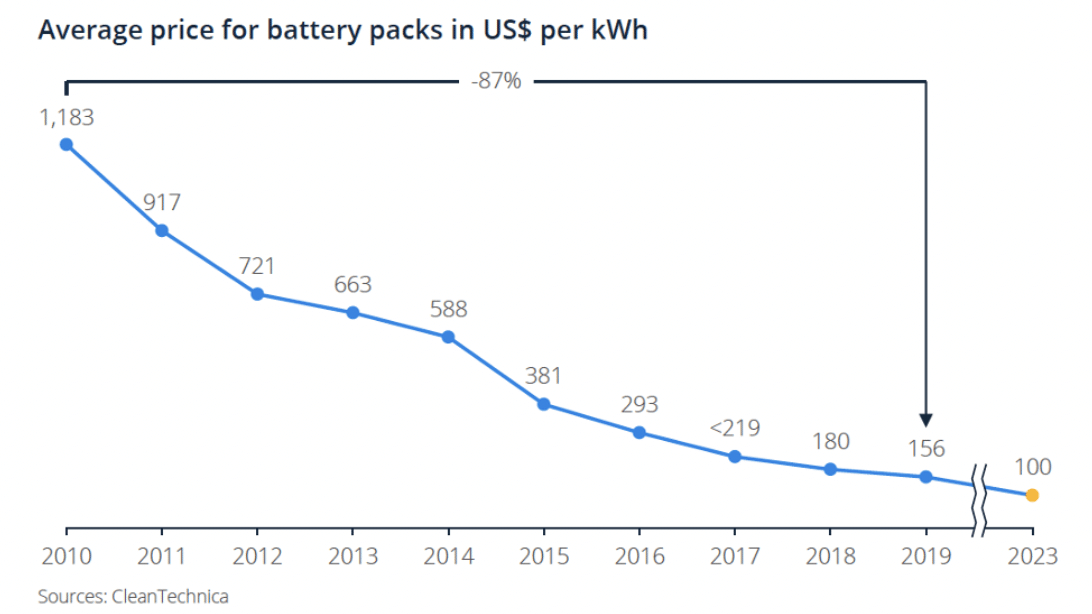

It is clear that consumers are already adopting EV technologies at an unprecedented pace, growing at a compounded annual growth rate (CAGR) of approximately 50% from 2012 to 2020. For those in need of a mathematics refresher, that means from 2012 to 2020, demand for electric vehicles grew, on average, 50% every year, and that is before any meaningful build-out of charging infrastructure or other manufacturers release their answer to electric vehicles. Finally, demand will continue to grow as the cost of battery technology declines. Simply put, the EV snowball is rolling, and automotive technicians must be ready.

EV Battery Pack Prices

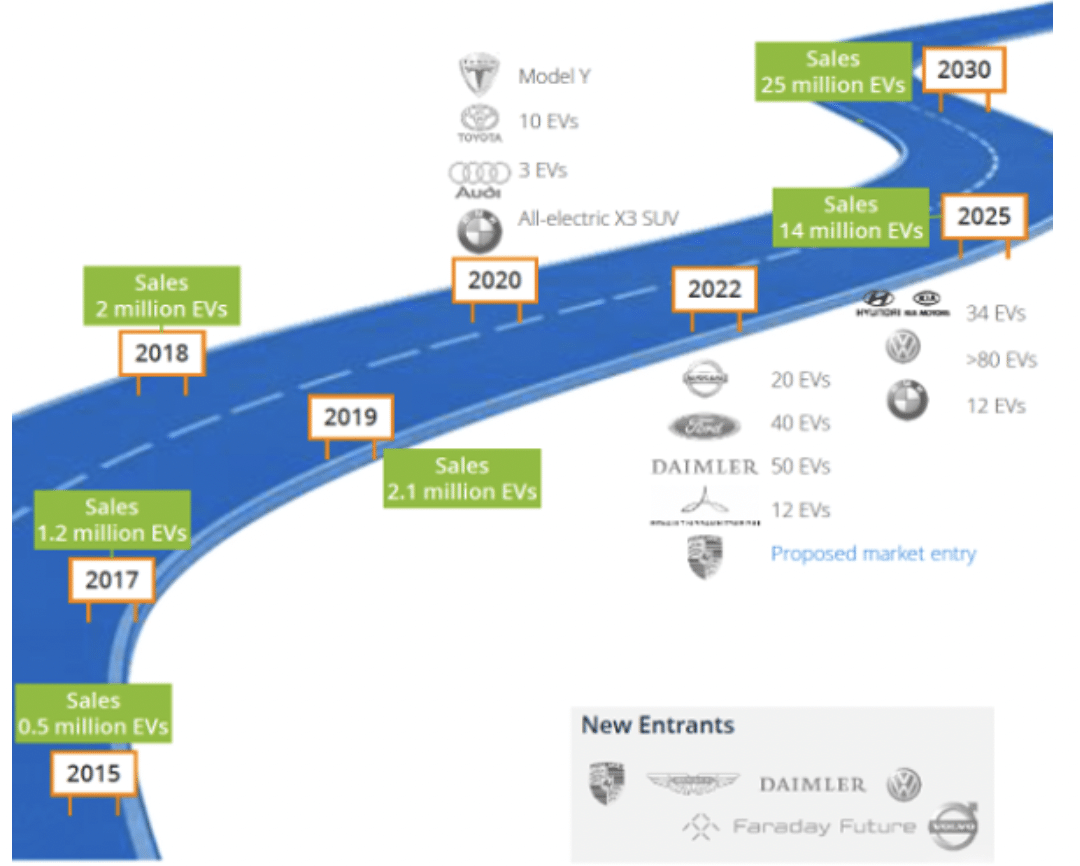

Increasing Electric Vehicle Selection

Tesla may have first-mover advantage, but they will soon be just one of many electric vehicles on the road. Every major manufacturer has committed unprecedented capital to transition their product offer to electric and hybrid.

In the U.S., GM committed $20 billion to electric and autonomous vehicles, with plans to release 20 EV options by 2023 (1 [https://www.govtech.com/fs/transportation/in-the-shift-to-evs-some-worry-workers-could-suffer.html]). In addition, Ford has reserved $11 billion for electric vehicles production by 2022 alone, including battery assembly and production of the new F-150 Hybrid, F-150 Lightning, the all-electric Mach-E, and its electric version of the Transit commercial van. Hummers are back as EVs, too?

That’s not to mention start-up electric vehicle companies like Rivian and Lucid, nor the rumors of Apple wanting to get into the EV game in the near future. What’s the point of all of this? To illustrate that some of the world’s largest and most powerful companies are heading in the direct of complete electrification of their fleets, and we must synchronously prepare ourselves and our workforce.

Key Players in the EV Industry

Charging Infrastructure

The last remaining impediment to complete EV adoption in the U.S. is already showing signs of crumbling, namely charging stations. Early this year, the Biden administration unveiled its plan to award nearly $5 billion over five years to build thousands of electric vehicle charging stations. This infrastructure build-out will enable electric vehicles to be a realistic option to consumers outside of highly urban areas.

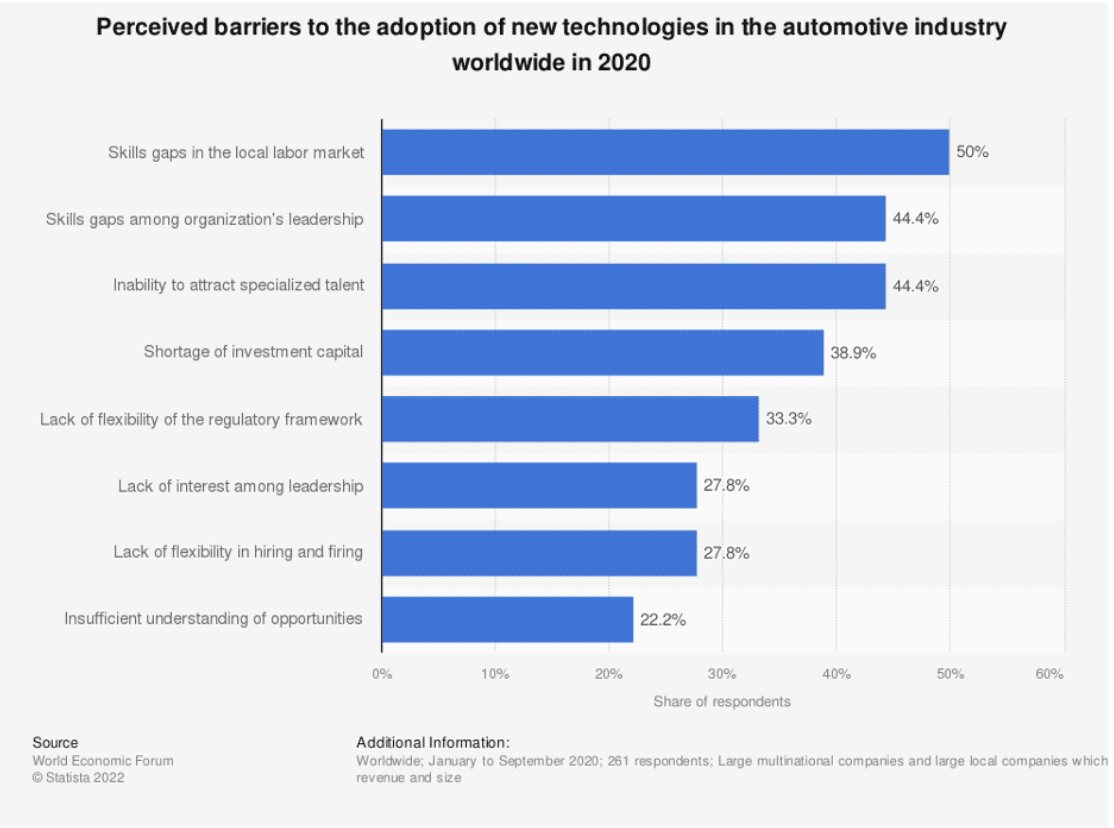

Demand for New Skills for Automotive Technicians

With the transition to electric vehicles comes the need to retrain service technicians, a group that is already strained to meet demand. In fact, according to the annual August report from the TechForce Foundation [https://techforce.org/news/], the demand for new vehicle mechanics outpaced the supply of new graduates by nearly three to one in 2020. Almost 400,000 additional automotive technicians will be needed from 2020 to 2024 to meet current demand. As the industry seeks to address the labor supply, it will also seek to address existing barriers to growth, such as the gap in needed skills.

According to The Economist [https://www.economist.com/science-and-technology/servicing-and-repairing-electric-cars-requires-new-skills/21805752], servicing and repairing electric vehicles will require starkly different skills from past vehicles and the technicians that aren’t retrained may be out of a job. Although the number of moving parts will shift from 20,000 with a standard internal combustion engine to 20 with an electric vehicle, the new technology will require technicians to be adept in concepts of electricity, electronics, and computer software.

With that being said, the data suggests that those who make the leap could enjoy a brighter future in an EV world. The Bureau of Labor Statistics indicates that top performing auto technicians will continue to enjoy salaries as high as $70,000, with the potential for even higher wage growth as demand for electric vehicles increase.

How Can TOOLKIT Help?

(1) DC Circuits and Ohm’s Law Training System – This trainer teaches basic electrical and electronic theory through the most commonly found electrical components found in modern vehicles.. It is designed to help teach Ohm’s Law basics as well as demonstrating common electrical system components and circuit operation – important concepts and skills for all vehicles, especially electric!

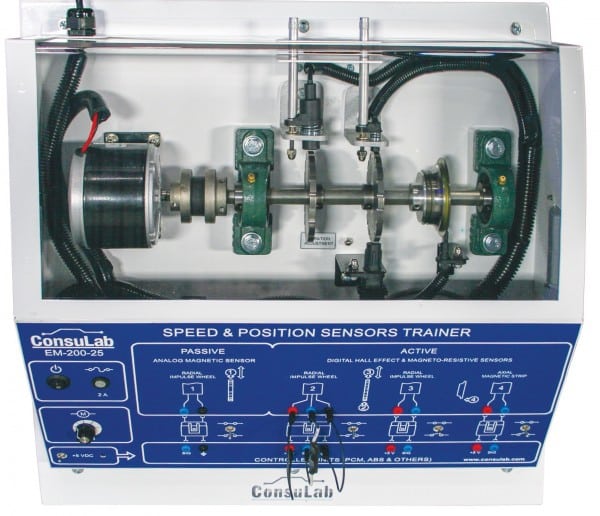

(2) Speed and Position Sensors Trainer – Providing a safe and effective method of demonstrating the operating principles of different types of speed and position sensors that are common on today’s cars and trucks. Normally used for wheel speed, engine speed and vehicle speed, all sensors are mounted on a common shaft which is driven by a variable speed electric motor to create different operating conditions.

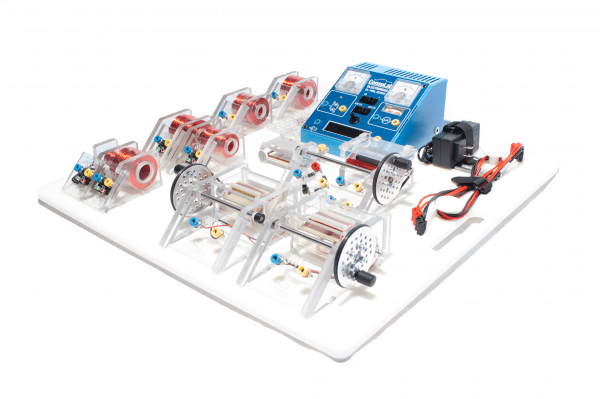

(3) Electromagnetism Training Systems – Designed for students to physically demonstrate, test, measure, and experience electromagnetism using a “hands-on” approach to learning, this trainer teaches the principle concepts and technologies around electromagnetism as it is applied to modern vehicles. Many aspects of a modern vehicle, whether a car, truck, combustion powered, hybrid or electrically driven, depend on some form of electromagnetism.

(4) Electric Vehicle Technology Trainer – The goal of this training equipment is to get students to know electric vehicle technology and the main technologies currently used in electric vehicles, as well as the behavior depending on the route and type of driving. See how acceleration, braking, inclines/slopes, etc affect the battery and performance of actual EVs.

(5) Hybrid Planetary Gearset Training System – This trainer is thoughtfully designed to illustrate the somewhat complex operation of a typical hybrid vehicle drivetrain. Based on a common Toyota Prius hybrid vehicle, the trainer provides easy visualization of driveline component operation including: ICE (Internal Combustion Engine), MG1 (Motor/generator # 1), MG2 (Motor/generator # 2), and Drive wheels.

(6) Toyota Prius Hybrid Engine Trainer with Faults – a complete Toyota Hybrid Engine Trainer designed specifically for teaching how a typical hybrid drive train operates. This trainer consists of all cutaway drive train components from a Toyota Hybrid Synergy Drive system including ICE (internal combustion engine), Torque damper assembly, MG1 (motor/generator #1), Planetary gearset (power split device), MG2 (motor/generator #2), Transaxle, Inverter, and HV (high voltage) battery (non-functional).

(7) Switch Electric Vehicle Kit – one of the most exciting education training systems available on the market today, our reusable Switch EV Kits allow students to build, wire, and drive a street-legal and fully-functioning electric vehicle! Complete with curriculum, instructor training, and classroom resources to teach Electric Vehicle concepts, technologies, and safety procedures, our Switch EV Kit is the perfect teaching platform for modern automotive and STEM classrooms.

GET IN TOUCH