Can Hands-on Training Be Remote?

The list of things the Covid-19 Pandemic taught us as a society is quite endless. For Career and Technical Education programs, it reinforced the notion that industrial technology and skilled trades courses must be taught in-person and hands-on.

At the same time, school shutdowns and lockdowns highlighted that perhaps more can be done to provide immersive and holistic training outside of the classroom or lab that is still meaningful. While nothing can replace hands-on, tactile training, we want to highlight some of the incredible tools that we believe provide great value to any technical education program – lockdown or not.

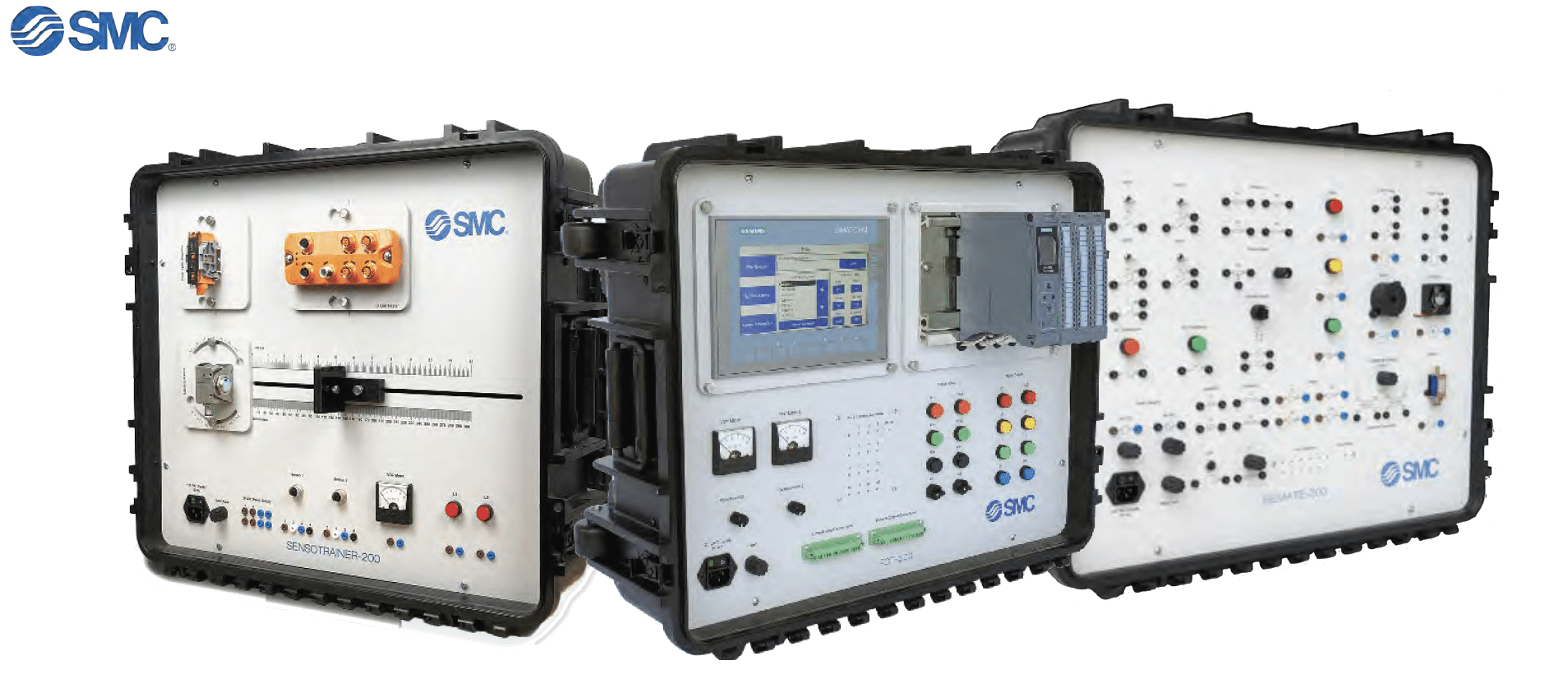

SMC Remote Access Box

SMC International Training – the training division of the world’s largest manufacturer of automation components for industry – created the RAB-400 – Remote Access Box for schools to provide access to technologies and training systems in classrooms and labs for students to view, monitor, control and program systems regardless of their location.

The RAB-400 includes a camera and stand, ethernet connection box, and software package that allows students from home to log in and use the training equipment in which schools have invested so much. Instructors can provide training from the labs, facilitate training activities and exercises, and can monitor students while they remotely train on Robots, PLCs, Integrated Mechatronics and Industry 4.0 Systems, and more. Up to 100 systems can be connected to the RAB-400 for students to remotely access and train.

How Can Remote Access Training Be Used in Post-Pandemic Classrooms?

There is great value in providing communities equitable access to learning despite socioeconomic conditions, geographic constraints, and general access to such training systems. As such, the RAB-400 enables schools to reach broader geographic areas and diverse groups of learners otherwise impossible to reach. More so, as schools look to become innovative training hubs whereby multiple school districts, technical colleges, communities, and industry partners work together, the RAB-400 empowers multiple stakeholders to “pull resources”, reach broader audiences, and achieve a greater ROI through industry training.

Portable + “Library-Enabled” Training Systems

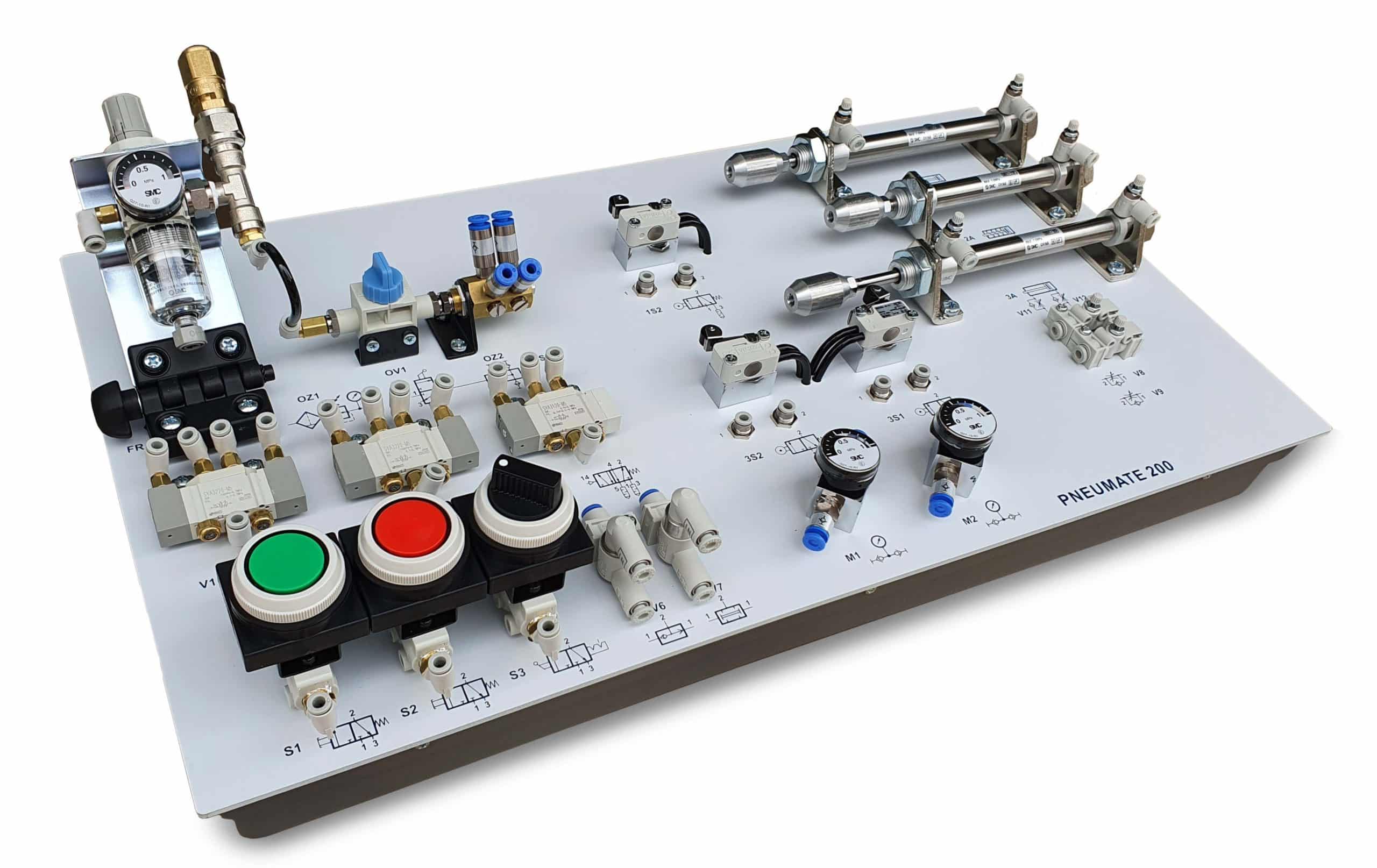

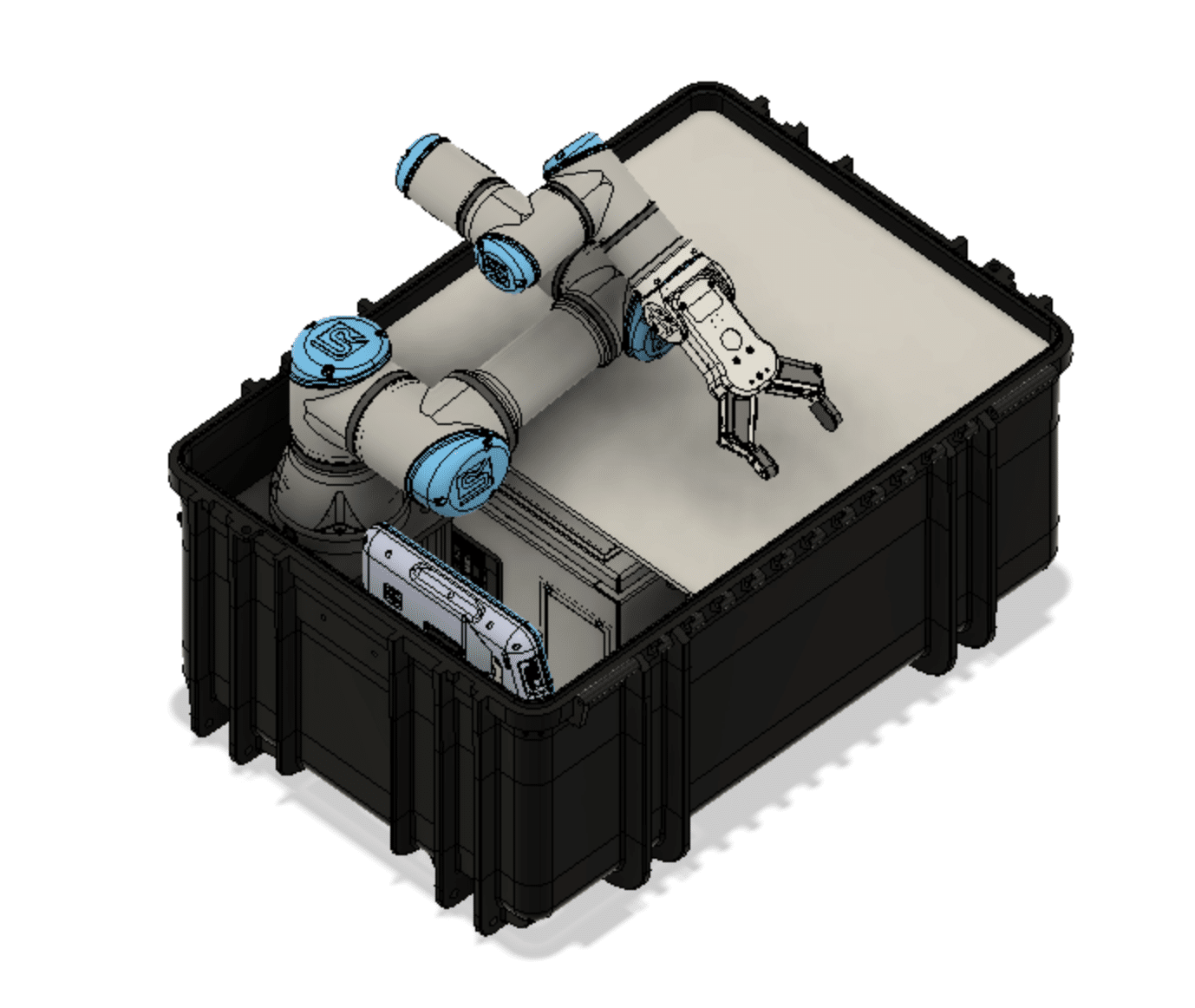

One of the simplest and most effective methods for providing “hands-on” training in remote learning environments is to actually provide students with physical training systems to take home with them. Our partners at ConsuLab and SMC International Training have created the perfect solution for this with Portable Suitcase Training Systems that enable students to take industry-relevant technologies home with them and learn hands-on industry-relevant skills.

In hybrid and remote learning environments, schools simply treat these training systems in the same manner as they treat library books: students check out for anywhere from 1-2 days or 1-2 weeks at a time, and return for the next learner.

It is remarkable to see the types of portable training systems that students now have access to, anywhere in the world!

Portable Suitcase Training Systems

- AC/DC Training System with Solid State

- Motor Controls

- Smart Sensors

- PLCs + HMIs

- Pneumatics + Electro-pneumatics

- Hydraulics – Excavator Kit

- Industrial Robotics *NEW

- Renewable Energy (Solar, Wind, Hydrogen)

Digital Twins: Industry 4.0 Benefits in the Classroom

One of the most exciting advancements currently taking place in industry currently revolves around Industry 4.0 and the use of Digital Twins in the manufacturing environment. Also known as “digital shadows” or “digitalization”, these software tools recreate real automation systems and processes in a digital environment in the exact same manner as the real-world. They are not simulations, but rather emulations that inform users exactly how real equipment, hardware, and technologies will operate in a particular environment with high fidelity and accuracy.

SMC is leaps and bounds above all others in terms of bringing this remarkable innovation and industrial tool to education with the release of their new SMCTwin-400 – Digital Twin Tool. The SMCTwin-400 allows users to emulate SMC Industrial Technologies and Integrated Training Systems for Mechatronics and Industry 4.0 from anywhere in the world via an internet browser.

Learners can view, program, monitor and make improvements to real industrial systems found in their classrooms (or real industrial environments) in a virtual environment, and experience them in the same manner they would expect as if they were standing directly in front of it.

One of our favorite ways of using this tool is for PLC programming – students can program any equipment or system in this virtual environment and see exactly how it would operate, before trying on the real system.

If you’re interested in learning more about any of these concepts, technologies, and general ideas for your program – reach out to TOOLKIT TECHNOLOGIES and speak with one of our technical education consultants for free.