Description

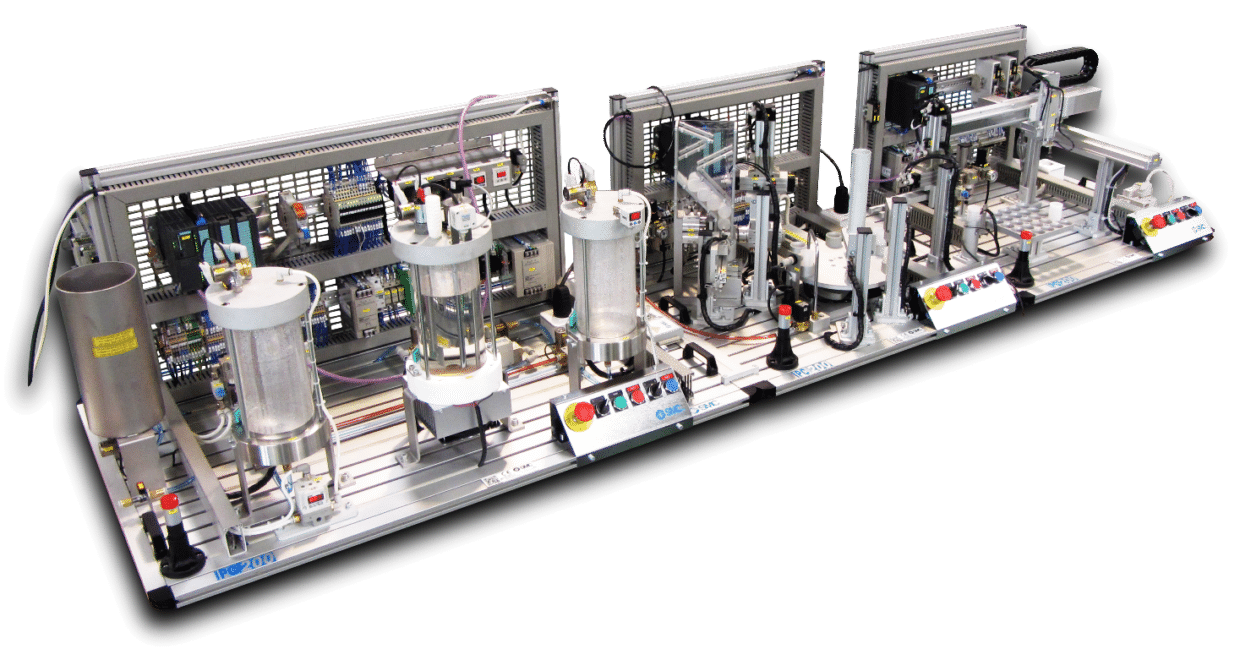

The system emulates an automated drink bottling and production plant. The system consists of three modules that share information through an industrial communications network and can be controlled through a SCADA application. The three modules are:

- Production

- Bottling

- Warehousing/Palletizing

IPC-201: Production Station

This first station represents the production and mixing of the liquid. It has three tanks: two at the side which store the raw material (liquid) and another in the middle where the mixing takes place.

This version of the production station can control digital variables.

IPC-201C: Production Station with Regulation and Control of Analog Variables

This version of the production station incorporates a series of elements regulate and control TEMPERATURE, LEVEL, PRESSURE and FLOW RATE.

This equipment is specially designed for the development of professional skills required in continuous process industry (in sectors such as food, pharmaceutical, chemical, petroleum, etc.).

The troubleshooting simulation system TROUB-200 is included, which generates up to 16 different breakdowns to be diagnosed by the user.

IPC-202: Bottling Station

The second IPC-200 station fills the bottles and feeds and positions lids. The bottles then move on to a third station for storage. All the operations carried out are distributed around a 6 positions index plate.

There are two versions of this station, depending on the bottle feeding module selected: a version with a gravity bottle feeder and another with a more complex feeder with position detection and automatic correction.

IPC-203: Warehouse and Palletizing Station

This station reproduces a 25 positions automatic warehouse by using a system based on three cartesian coordinate (two horizontal electric axes and one vertical pneumatic axis).

Supervisory Control and Data Acquisition System

It allows the following processes in the first module:

- Supervise variables such as pressure, flow, level and temperature.

- Change PID setpoint and control parameters.

- Open-loop mode.

- Closed-loop via PLC mode.

- Closed-loop via PID mode.

It also allows the three system modules to be controlled and monitored remotely through a graphic interface implemented in a software application: